KIA Niro: Fuel Pressure Sensor (FPS)

Description

Installed on top of the low pressure fuel pump, the Fuel Pressure Sensor (FPS) measures the pressure in the low pressure fuel line.

Based on the fuel pressure measured by the FPS and the amount of fuel consumed,

the fuel pump

control module (FPCM) determines whether to activate the low pressure fuel pump.

After activating

the low pressure fuel pump, the FPS continues to send the fuel pressure to the

FPCM and the FPCM

keeps controlling the fuel flow rate using the feedback from the FPS.

Circuit Diagram

Fail-Safe Mode

Warning

If the fuel pressure sensor malfunctions, it enters fail safe mode. This means that the fuel pressure rises to match the increased level of current while the pressure in the low pressure fuel line remains static despite the rise in fuel pressure.

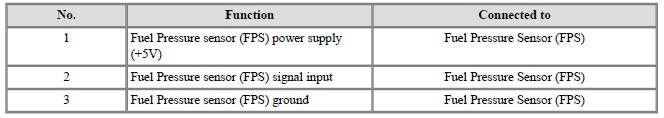

Terminal

Information

Terminal Illustration

Terminal Function

Inspection

- Connect the KDS on the Data Link Connector (DLC).

- Check that the output voltage is within the specification.

Fuel Pump Control Module (FPCM) Repair procedures

Removal

- Release the residual pressure in fuel line.

(Refer to Fuel Delivery system - "Release Residual Pressure in Fuel Line")

- Switch "OFF" the ignition and disconnect the negative (-) battery terminal.

- Remove the rear seat cushion.

( Refer to Body - "Rear Seat Assembly" )

- Remove the fuel pump service cover (A).

Warning

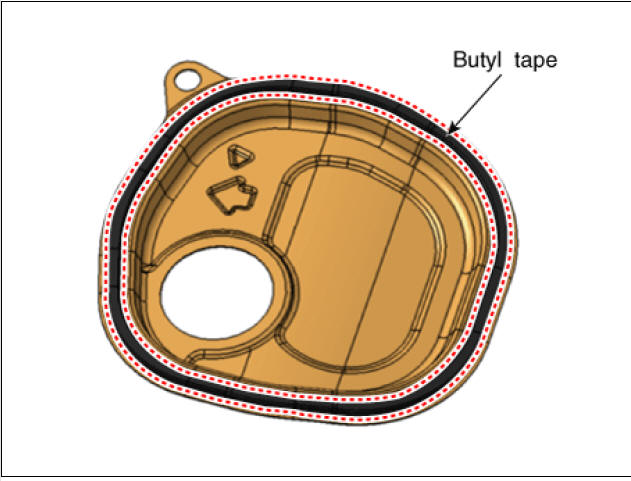

- When reinstalling a protective cover for a fuel pump, remove the existing butyl tape and apply a new one.

- Before assembling the protective cover, ensure that the

temperature of the butyl is about 30º

C using a hair dryer or a heat gun.

Warning

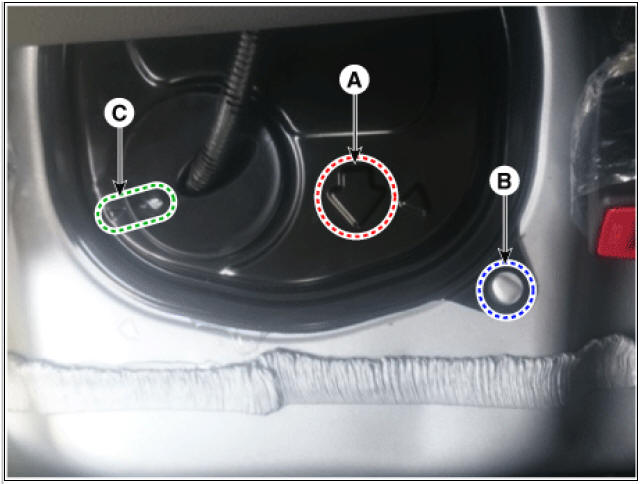

When installing the protective cover for the fuel pump, pay attention to the installation direction of the grommet and the protective cover.

- The arrow (A) should be in the forward direction of the car.

- Align the bulging part of the vehicle body (B) with the hole of the protective cover.

- Align the bulging part of the grommet (C) with the bulging part

of the protective cover.

- Disconnect the fuel pressure sensor connector (A).

- Remove the fuel pressure sensor fixing pin (A).

- Remove the fuel pressure sensor (B) from the fuel pump.

Installation

- Install in the reverse order of removal.

READ NEXT:

Delivery Pipe Repair procedures

Delivery Pipe Repair procedures

Removal

Warning

In case of removing the high pressure fuel pump, high pressure fuel

pipe, delivery pipe, and injector, there

may be injury caused by leakage of the high pressure fuel. So don't do any

repair work right after engine

stops.

High Pressure Fuel Pump Repair procedures

High Pressure Fuel Pump Repair procedures

Warning

In case of removing the high pressure fuel pump, high pressure fuel

pipe, delivery pipe, and injector, there may be injury

caused by leakage of the high pressure fuel. So don't do any repair work right

after engine stops.

Release th

Engine Clutch System

Engine Clutch System

Specifications

Clutch Cover and Disc

Engine Clutch Actuator

Service Standard

Tightening Torques

Lubricants

Special Service Tools

Tool Name /

Number/

Illustration / Description

Clutch disc

guide

09411-1P000/ /Use

SEE MORE:

Sun Visor | Roof Trim Assembly

Sun Visor | Roof Trim Assembly

Sun visor

Retainer

Replacement

Remove the cap (A) by using a remover.

Remove the retainer (A) after loosening the screw.

Remove the sun visor (A) after loosening the screws.

Install in the rever

Replacing inner panel

fuse

Replacing inner panel

fuse

Operation

Turn the vehicle and all other switches

off.

Open the fuse panel cover.

Pull the suspected fuse straight out.

Use the removal tool (1) provided in

the main fuse box in the engine compartment.

Check the remove

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us