KIA Niro: High Pressure Fuel Pump Repair procedures

Warning

In case of removing the high pressure fuel pump, high pressure fuel pipe, delivery pipe, and injector, there may be injury caused by leakage of the high pressure fuel. So don't do any repair work right after engine stops.

- Release the residual pressure in fuel line.

(Refer to the Fuel Delivery System - "Release Residual Pressure in Fuel Line").

- Switch "OFF" the ignition and disconnect the negative (-) terminal of the auxiliary 12V battery.

- Remove the air cleaner and intake hose.

(Refer to Mechanical System - "Air Cleaner")

- Disconnect the fuel pressure control valve connector (A).

- Disconnect the feed tube quick-connector (B) by using a clip tool.

Warning

Open the clamp cover (B) before disconnecting the quick connector

(if the clip is applied).

Warning

When removing the quick-connnector with the clip removing tool (A), be careful not to damage the plastic clip (B).

Damaged clip can result in fuel line leakage due to bad connection.

- Remove the high pressure fuel pipe.

(Refer to Fuel Delivery System - "Fuel Line")

- Remove the installation bolts (A), and then remove the high pressure fuel pump (B) from the cylinder head assembly.

High pressure fuel pump mounting bolt: 12.8 - 14.7 N*m (1.3 - 1.5 kgf*m, 9.4 - 10.9 lb*ft)

Warning

Unscrew in turns the two bolts in small steps (0.5 turns). If one of the two bolts is fully unscrewed with the other still intact, the housing surface of the cylinder head may get broken due to the tension of the pump spring.

Installation

Warning

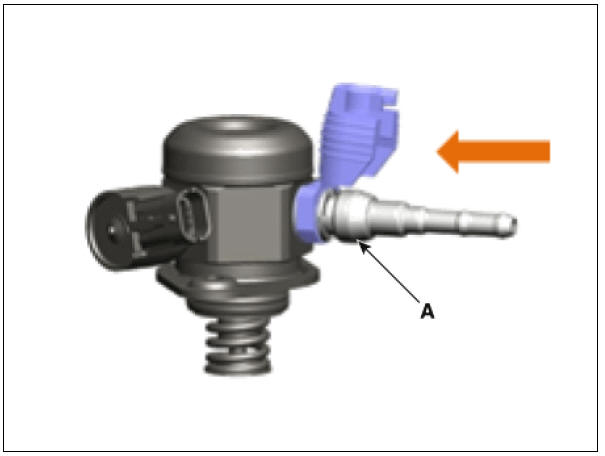

To ensure that the low pressure fuel hose quick-connector (A) is

completely engaged to the high pressure fuel pump, push it in

until it clicks.

- To double check that the low pressure fuel hose is completely engaged to the high pressure fuel pump, pull it after connecting.

- Install the clamp cover (A) to tighten the quick-connector

completely.

- Be sure to install the high pressure fuel pipe (B) to the

specified torque.

- Securely inspect leakage of all fuel line connection parts at engine start condition.

Warning

Before installing the high pressure fuel pump, position the roller tappet in the lowest position by rotating the crankshaft.

Otherwise the installation bolts may get broken due to tension of the pump spring.

Warning

Do not reuse bolts.

Warning

Do not reuse high pressure fuel pipes.

Warning

When tightening the installation bolts of the high pressure fuel pump, tighten in turns the bolts in small steps (0.5 turns) after pre-tightening them by hand.

Warning

- Install the component to the specified torque.

- First hand-tighten the fasteners fully until they are not

fastened any more in order to have them inserted in place and then

completely tighten to the specified torque using a torque wrench.

If the bolts or nuts are not tightened in a straight line with the mating bolt holes or fittings, fuel leakage may occur due to broken threads.

Warning

Note that internal damage may occur when the component is dropped. In this case, use it after inspecting.

Warning

Apply engine oil to the O-ring (A) of the high pressure fuel pump,

the roller tappet (B), and the protrusion (C). Also apply

engine oil to the groove on the location where the protrusion (C) is installed.

- Install in the reverse order of removal.

Warning

Use the special service tool (SST No.: 09314-3Q100 or 09314-27130) to install the high pressure fuel pipe.

READ NEXT:

Engine Clutch System

Engine Clutch System

Specifications

Clutch Cover and Disc

Engine Clutch Actuator

Service Standard

Tightening Torques

Lubricants

Special Service Tools

Tool Name /

Number/

Illustration / Description

Clutch disc

guide

09411-1P000/ /Use

Engine Clutch Actuator

Engine Clutch Actuator

Components

Clutch disc

Clutch cover

Concentric slave cylinder

Hybrid motor assembly

Engine clutch actuator

Reservoir

Specifications

Schematic Diagrams

Harness Connector

Engine Clutch Actuator Repair procedu

Concentric Slave Cylinder Assembly Repair procedures

Concentric Slave Cylinder Assembly Repair procedures

Removal

Remove the hybrid motor assembly.

(Refer to Hybrid Motor System - "Hybrid Motor Assembly")

Remove the engine clutch actuator.

(Refer to Engine Clutch System - "Engine Clutch Actuator")

Remove the adapter (A

SEE MORE:

Power Window Motor

Power Window Motor

Power Window Motor Components and components location

Power Window Motor Schematic diagrams

Power Window Motor Repair procedures

Inspection

Front Power Window Motor

Remove the front door trim.

(Refer to Body - "Front Door Trim&

High Voltage Battery System / Components And Components Location

High Voltage Battery System / Components And Components Location

Description

The High Voltage Battery System provides the hybrid drive motor, HSG, and

electric A/C compressor

with electric energy and also reserves the electric energy generated during

regeneration braking.It

consists of the battery pack asse

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us