KIA Niro: Engine Clutch System

Specifications

Clutch Cover and Disc

Engine Clutch Actuator

Service Standard

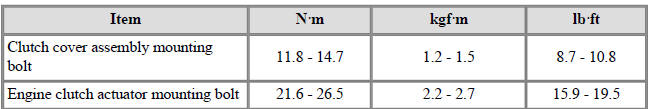

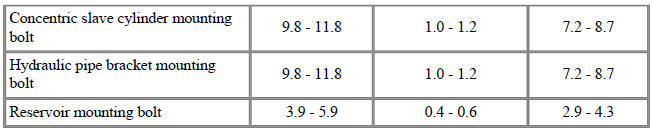

Tightening Torques

Lubricants

Special Service Tools

Tool Name /

Number/

Illustration / Description

Clutch disc

guide

09411-1P000/  /Used for fixing

clutch disc assembly

/Used for fixing

clutch disc assembly

when installing

clutch cover

assembly.

Used with the

adapter (09411-

G2100)

Adapter

09411-G2100/  / Used for fixing

clutch disc assembly

/ Used for fixing

clutch disc assembly

when installing

clutch cover

assembly.

Used with the clutch

disc guide (09411-

1P000)

Removal

- Remove the engine clutch reservoir cap (A).

Warning

If use the engine clutch fluid syringe.

- Drain the engine clutch fluid from the reservoir using a syringe.

If do not use the engine clutch fluid syringe.

1) Remove the engine under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

2) Drain the engine clutch fluid after remove the engine clutch fluid hose (A).

Warning

Do not spill brake fluid on the vehicle, it may damage the paint. if brake fluid does contact the paint, wash it off immediately with water.

Installation

- Install in the reverse order of removal.

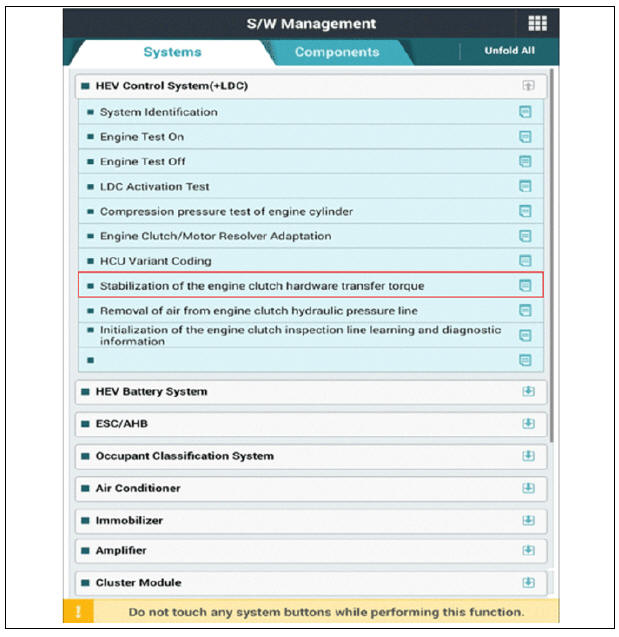

- Operate by using KDS as in the order below after filling regulation hydraulic fluid in reservoir.

Specified hydraulic fluid : Brake fluid DOT 3 Quantity : Fill the hydraulic fluid to the reservoir so that it comes between the MAX and MIN levels of the reservoir.

(1) Perform initialization of the engine clutch inspection line learning and diagnostic information.

(2) Bleed the air from engine clutch hydraulic pressure line.

Warning

Be sure to bleed air from the engine clutch hydraulic pressure line at outside temperature between 0 - 40ºC (32 - 104ºF). If not, the air bleeding would be not done well.

Warning

Refil the hydraulic fluid to MAX-MIN level, if the fluid is lower than MIN level while performing the air bleeding.

(3) Perform engine clutch/motor resolver adaptation.

(4) Perform stabilization of the engine clutch hardware transfer torque.

- Engine Clutch Actuator

- Concentric Slave Cylinder Assembly Repair procedures

- Clutch Cover And Disc Repair procedures

- Reservoir Repair procedures

READ NEXT:

Engine Clutch Actuator

Engine Clutch Actuator

Components

Clutch disc

Clutch cover

Concentric slave cylinder

Hybrid motor assembly

Engine clutch actuator

Reservoir

Specifications

Schematic Diagrams

Harness Connector

Engine Clutch Actuator Repair procedu

Concentric Slave Cylinder Assembly Repair procedures

Concentric Slave Cylinder Assembly Repair procedures

Removal

Remove the hybrid motor assembly.

(Refer to Hybrid Motor System - "Hybrid Motor Assembly")

Remove the engine clutch actuator.

(Refer to Engine Clutch System - "Engine Clutch Actuator")

Remove the adapter (A

Clutch Cover And Disc Repair procedures

Clutch Cover And Disc Repair procedures

Removal

Remove the hybrid motor assembly.

(Refer to Hybrid Motor System - "Hybrid Motor Assembly")

Remove the clutch cover assembly and clutch disc after loosening the

bolts.

Warning

Be careful not to be bent or twist b

SEE MORE:

AHB Brake System Bleeding procedure

AHB Brake System Bleeding procedure

The iBAU consists of 3 brake fluid lines in total (Low/high pressure and

pedal simulator lines), therefore, air bleeding should be made

sequentially following the procedure below.

Bleeding sequence : Low pressure/Pedal simulator section (

High voltage battery warmer system

High voltage battery warmer system

The high voltage battery warmer system

prevents reduction of battery output

when battery temperature is low. If the

charging connector is connected, the

warmer system automatically operates

according to the battery temperature.

Charging time

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us