KIA Niro: Clutch Cover And Disc Repair procedures

Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual / Engine Clutch System / Clutch Cover And Disc Repair procedures

Removal

- Remove the hybrid motor assembly.

(Refer to Hybrid Motor System - "Hybrid Motor Assembly")

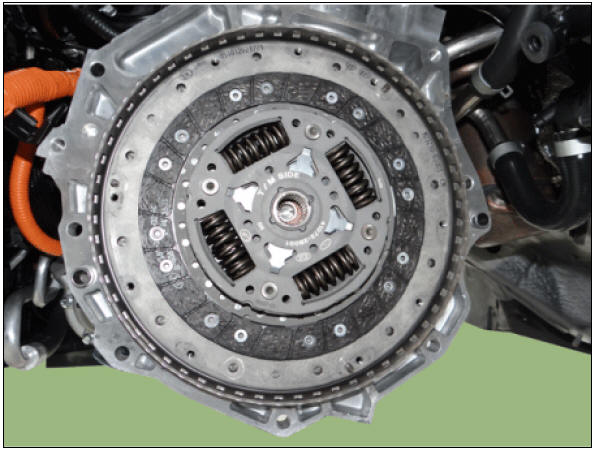

- Remove the clutch cover assembly and clutch disc after loosening the bolts.

Warning

Be careful not to be bent or twist bolts. Loosen bolts in diagonal directions.

Inspection

- Inspect diaphragm spring wear which is in contact with a concentric slave cylinder bearing.

- Check the clutch cover and disc surface for wear or cracks.

- Check the clutch disc lining for slipping or oil marks.

- Measure the depth from a clutch lining surface to a rivet. If the measured value is less than the specification below, replace it

Clutch disc depth (A): 6.4 +- 0.2 mm (0.2519 +- 0.0078 in.) Clutch disc rivet depth (B): 0.3 mm (0.0118 in.)

Installation

Warning

- If reinstalling used cover, the cover should be installed with its clutch disc as a set.

- If you only replace a disk, the adjustment ring may

malfunction, resulting in a slip due to the initial decrease of clamp load.

(This is because the clutch cover is adjusted by as much as the amount of its wear.)

- If you only replace a disk, the disk may exceed its acceptable thickness for assembly, making it difficult to block the driving force.

- Apply grease on a disc spline part and hybrid motor input shaft spline part as required.

Warning

- When not applying: Excessive wear of splines and bad clutch operation can occur.

- When excessively applying: Grease can be scattered by centrifugal force which can contaminate the clutch disc. This can cause a loss of friction force causing a slip.

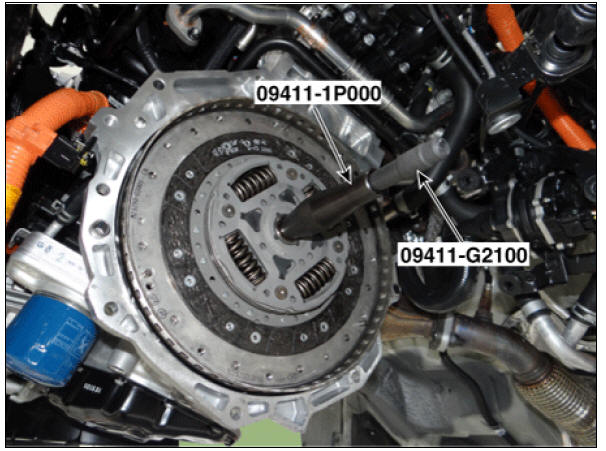

- The 'T/M SIDE' marked surface should face the transaxle.

- Install the clutch disc and the cover with SST (09411-1P000, 09411-G2100).

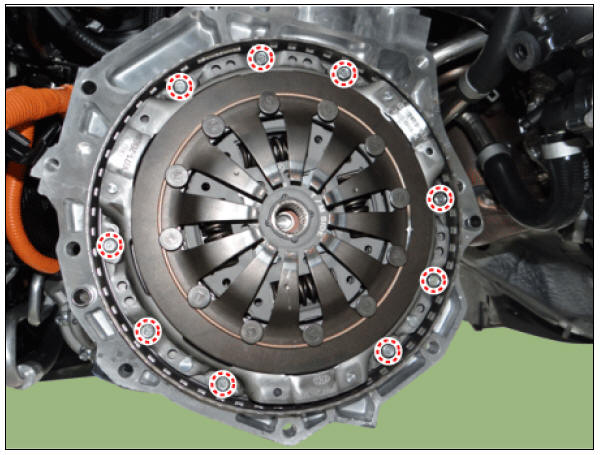

- Install the clutch cover bolts.

Warning

- Loosely tighten every clutch cover bolts, then torque to

specifications in a diagonal direction.

This can prevent twisting, vibration of the cover, and the lifting of the pressure plate.

- Install the all the components with the specified torques. If not, the clutch torque transaxle may have concerns or the mounting bolt can loosen.

- Install the hybrid motor assembly.

(Refer to Hybrid Motor System - "Hybrid Motor Assembly")

- After replacing the concentric slave cylinder assembly, operate the followings in order using KDS.

(1) Perform initialization of the engine clutch inspection line learning and diagnostic information.

READ NEXT:

Reservoir Repair procedures

Reservoir Repair procedures

Removal

Turn the ignition switch OFF and disconnect the battery (-) terminal.

Drain the hydraulic oil from the reservoir using a syringe.

Loosen the reservoir hose (A) and bolts (B) and then remove the

reservoir.

Tightening torque :

3.

DCT(Dual Clutch Transmission) System

DCT(Dual Clutch Transmission) System

Specifications

Double Clutch Transmission

Warning

Refer to oil replacement procedure due to drained oil quantity

can be more or less than oil

capacity.

If genuine DCT oil that is developed for best performance is

not using, it may

DCT (Dual Clutch Transmission) System - Troubleshooting

DCT (Dual Clutch Transmission) System - Troubleshooting

Trouble symptom:

Warning lamp ""E"" is illuminated(Driving is only possible with 1/R gear)

Probable cause → Remedy

DCT learning not performed → Perform the DCT manual l

SEE MORE:

High Beam Assist (HBA)

High Beam Assist (HBA)

High Beam Assist (HBA) (if equipped) (Kia NIRO Hybrid)

High Beam Assist is a function that automatically

adjusts the headlamp range

(switches between high beam and low

beam) depending on the brightness of

detected vehicles and certain road c

Driver Airbag (DAB) Module and Clock Spring

Driver Airbag (DAB) Module and Clock Spring

Driver Airbag (DAB) Module and Clock Spring Description and operation

Description

Driver Airbag (DAB) is installed in the steering wheel and electrically

connected to SRSCM via the

clock spring.

It protects the driver by deploying the airbag

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us