KIA Niro: Low Voltage DC/DC Converter (LDC)

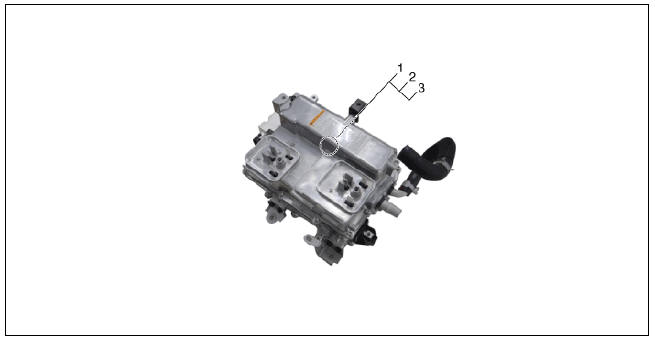

Component Location

- Low Voltage DC/DC Converter (LDC) (HPCU)

- Low Voltage DC/DC Converter (LDC) power output terminal (+) (DC 12V)

- Low Voltage DC/DC Converter (LDC) ground terminal (-)

Schematic Diagram

Low Voltage DC/DC Converter (LDC) / Repair Procedures

Removal

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to read and follow the "High Voltage Shut-off

Procedures" before doing any work related with the high voltage system.

Failure to follow the safety instructions may result in serious electrical injuries.

- Shut off the high voltage.

(Refer to "High voltage Shut-off Procedures")

- Remove the air cleaner assembly and air duct.

(Refer to Engine Mechanical System - "Air Cleaner")

- Remove the ECM & TCM bracket assembly.

(Refer to Engine Control/Fuel System - "Engine Control Module")

- Drain the coolant of hybrid motor cooling system.

(Refer to Hybrid Motor Cooling System - "Coolant")

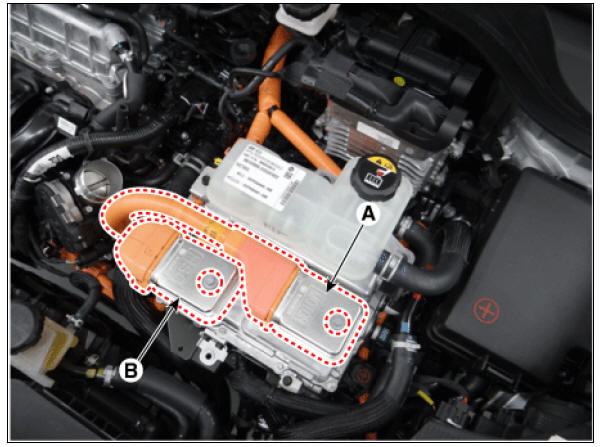

- Disconnect the motor power cable connector (A) and HSG power cable connector (B) after loosening the mounting bolts.

- Disconnect the power cable (A) and inverter power cable (B) from the HPCU.

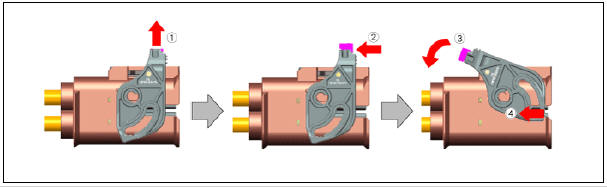

Warning

Remove the inverter power cale in the follwing order.

- Disconnect the HCU & inverter (MCU) connector (A).

- Disconnect the coolant outlet hose & pipe after loosening the mounting bolt (A).

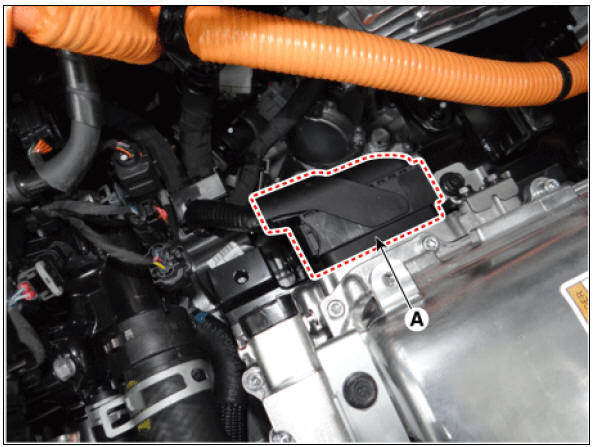

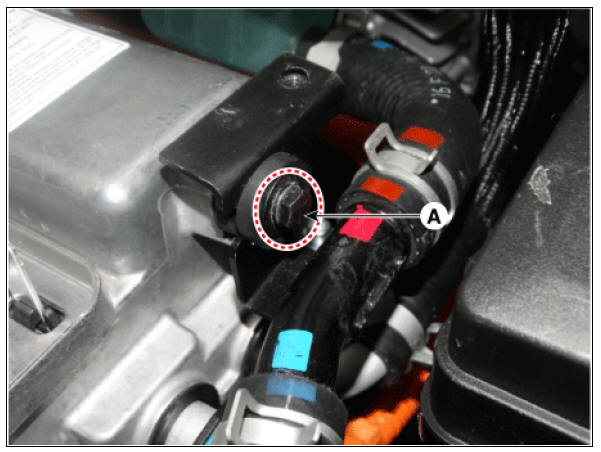

- Disconnect the coolant inlet hose quick-connector (A).

- Remove the LDC power outlet cable mounting bolt (A) and ground cable bolt (B).

- Remove the HPCU (A) after loosening the mounting bolts.

Installation

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to read and follow the "High Voltage Shut-off

Procedures" before doing any work related with the high voltage system.

Failure to follow the safety instructions may result in serious electrical injuries.

- Install the LDC in the reverse order of removal.

- Refill the hybrid motor cooling system coolant and perform air bleeding

by using the KDS.

(Refer to Hybrid Motor Cooling System - "Coolant")

Warning

Perform HCU Variant Coding and Engine Clutch / Motor Resolver learning after replacing the HPCU.

HCU Variant Coding

- Turn the ignition switch OFF.

- Connect the KDS to Data Link Connector (DLC).

Turn the ignition switch ON.

- Select "Vehicle, Model year, Engine, System".

- Select "Vehicle S/W Management".

- Select "HCU Variant Coding".

Engine clutch/motor resolver adaptation

- Turn the ignition switch OFF.

- Connect the KDS to Data Link Connector (DLC).

Turn the ignition switch ON.

- Select "Vehicle, Model year, Engine, System".

- Select "Vehicle S/W Management".

- Select "Engine clutch/motor resolver adaptation.".

READ NEXT:

Hybrid Drive Motor Assembly Repair procedures

Hybrid Drive Motor Assembly Repair procedures

Description

The hybrid motor system is equipped with two electric motors - HSG and

drive motor.

The traction motor operates to move the vehicle, to reduce Noise,

Vibration, and Harshness (NVH) while driving and to

improve fuel efficienc

Hybrid Starter Generator(HSG) Repair procedures

Hybrid Starter Generator(HSG) Repair procedures

Hybrid Starter Generator(HSG) Components and components location

Components

Hybrid starter generator (HSG)

HSG bracket

Specification

Hybrid Starter Generator(HSG) Repair procedures

Inspection

Inspect the line to line resistanc

SEE MORE:

Regenerative braking mode

Regenerative braking mode

Operation

Pull the left side (-) of the paddle

shifter to increase regenerative braking

and deceleration.

Pull and hold the left side (-) of the

paddle shifter to reach MAX and stop

the vehicle.

Pull the right side (+) of the

Room Lamp Repair procedures | Vanity Lamp Repair procedures

Room Lamp Repair procedures | Vanity Lamp Repair procedures

Removal

Warning

Put on gloves to prevent hand injuries.

When removing with a flat-tip screwdriver or remover, wrap protective tape around the tools to prevent damage to components.

Disconnect the negative (-) battery terminal

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us