KIA Niro: Hybrid Drive Motor Assembly Repair procedures

Description

- The hybrid motor system is equipped with two electric motors - HSG and drive motor.

- The traction motor operates to move the vehicle, to reduce Noise, Vibration, and Harshness (NVH) while driving and to improve fuel efficiency.

- The electric motor takes on the role of a generator during deceleration and braking.

- The Hybrid Starter Generator (HSG) starts the engine while the vehicle is in motion.

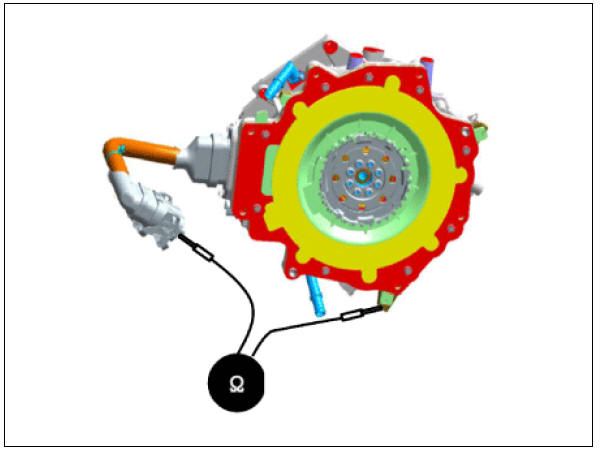

Hybrid Drive Motor Assembly Components and components location

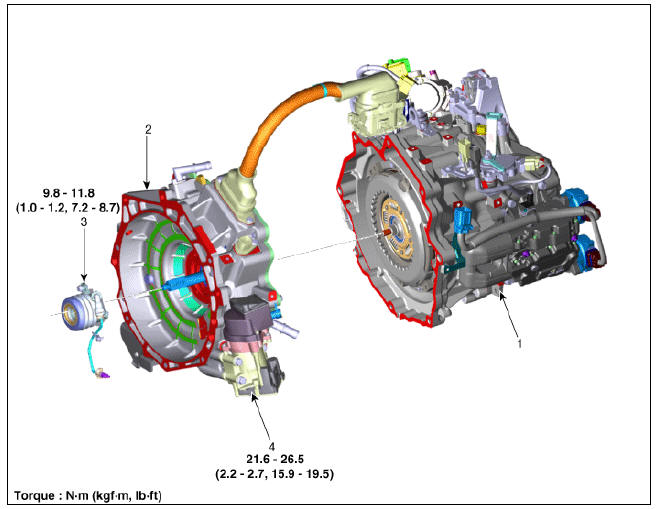

Components

- Dual clutch transmission (DCT) assembly

- Hybrid drive motor assembly

- Concentric slave cylinder

- Engine clutch actuator assembly

Specification

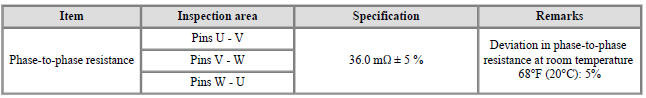

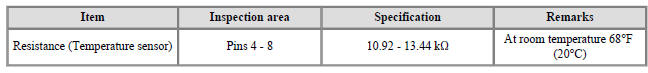

Inspection

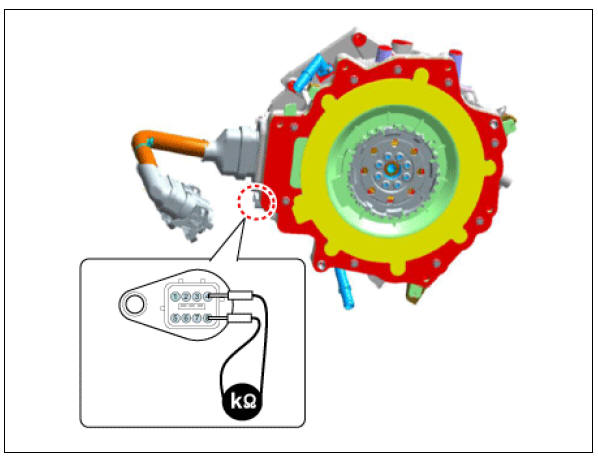

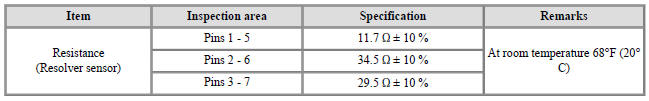

- Using mΩ tester, measure the line-to-line resistance.

Hybrid Drive Motor Assembly Repair procedures

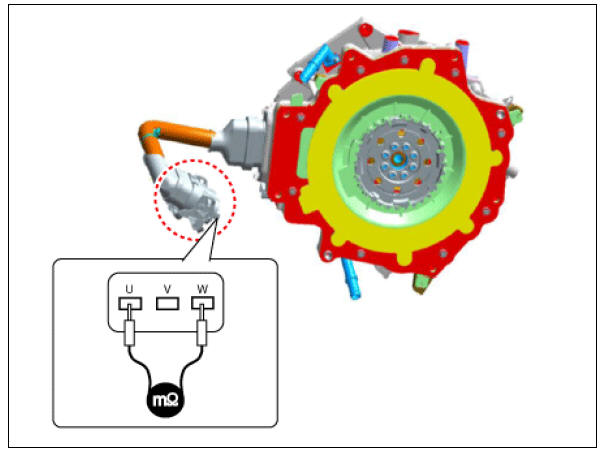

- Inspect the temperature sensor resistance.

- Inspect the resolver sensor resistance.

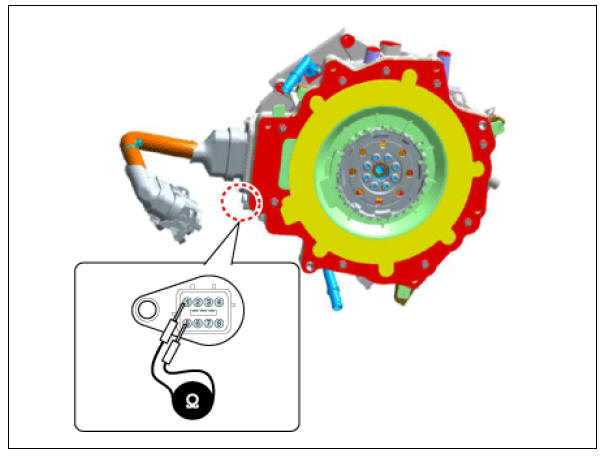

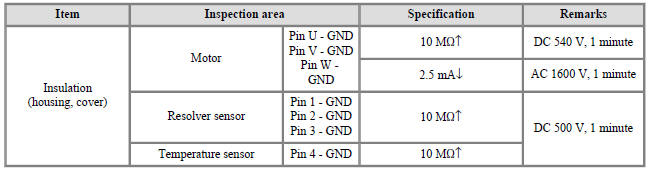

- Inspect the insulation resistance.

Removal

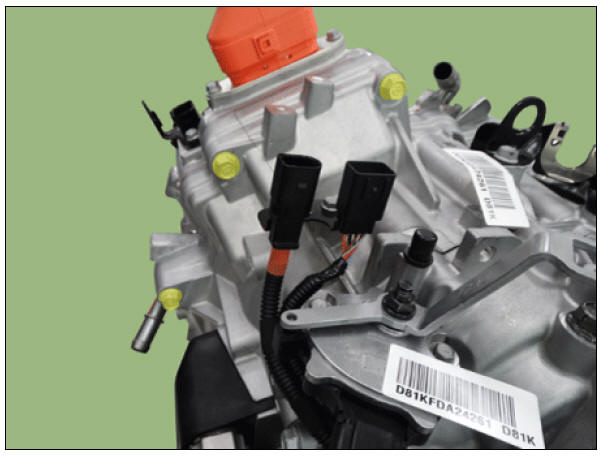

- Remove the hybrid drive motor & dual clutch transmission assembly from

the vehicle.

(Refer to DCT System - "DCT")

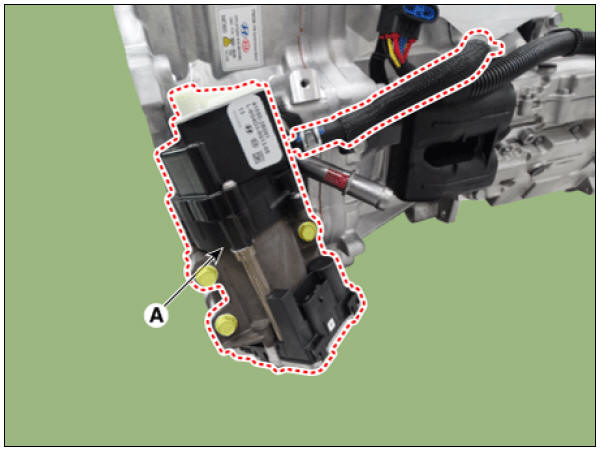

- Remove the engine clutch actuator (A).

Tightening torque : 21.6 - 26.5 N*m (2.2 - 2.7 kgf*m, 15.9 - 19.5 lb*ft)

- Remove the concentric slave cylinder.

(Refer to Engine Clutch System - "Concentric Slave Cylinder Assembly")

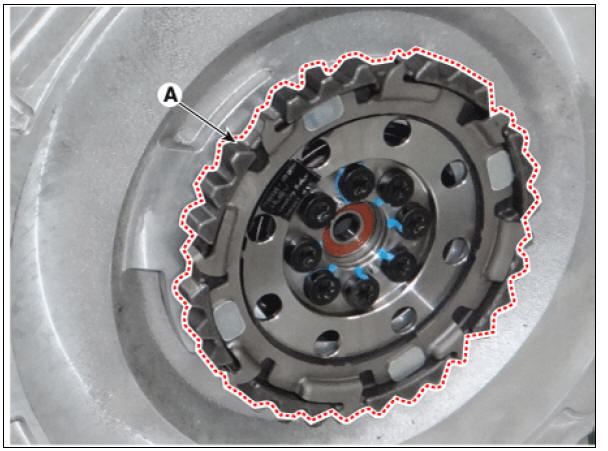

- Remove the hybrid drive motor (A) by loosening the bolts.

Tightening torque : 42.2 - 53.9 N*m (4.3 - 5.5 kgf*m, 31.1 - 39.8 lb*ft)

Installation

- Install in the reverse order of removal.

Warning

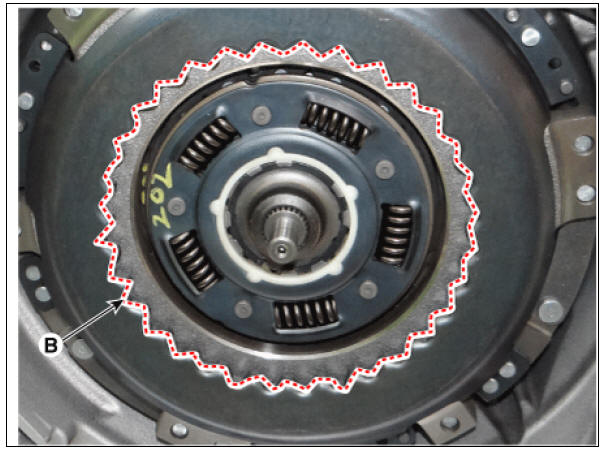

1) Check the pilot bearing (B) and motor side connector (A) on the

side of engine for any dents, damages and deformations

before installing the DCT.

2) Align the motor side connector spline (A) with the dual clutch

spline (B).

3) Insert the input shaft (A) into the pilot bearing (B) and then

assemble the DCT to the bushing on the motor side.

4) After mounting the DCT to the engine by pushing the DCT, tighten the mounting bolts making sure that there is no gap (less than 2 mm) between the clutch housing and the engine block.

(If the bolt is tightened while there is a gap, then the spline of motor side connector or clutch will be damaged or broken.)

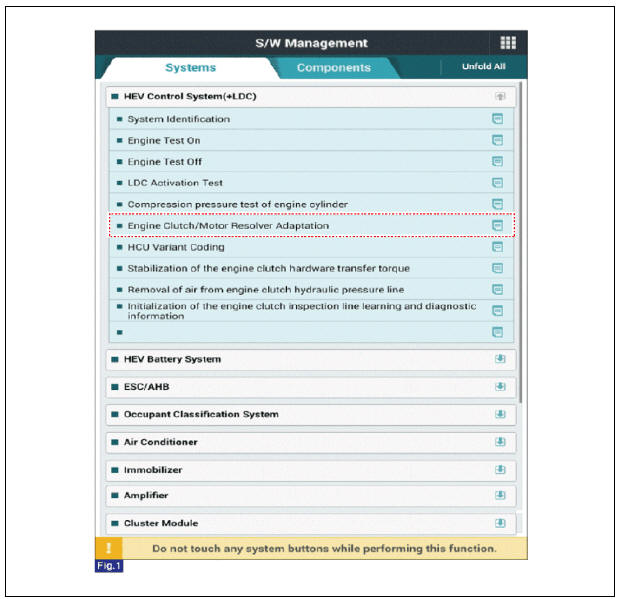

- Perform the procedure below after installing.

(1) Refill the hybrid motor cooling system with coolant and then perform the air bleeding using the KDS.

(Refer to Hybrid Motor System - "Coolant") (2) Perform learning of the engine clutch inspection line and initialization of diagnostic information using the KDS.

(3) Refill the engine clutch reservoir with brake fluid and then perform the air bleeding using the KDS.

(4) Perform the engine clutch / motor resolver adaptation using the KDS.

(5) Stabilize the engine clutch hardware transfer torque using the KDS.

READ NEXT:

Hybrid Starter Generator(HSG) Repair procedures

Hybrid Starter Generator(HSG) Repair procedures

Hybrid Starter Generator(HSG) Components and components location

Components

Hybrid starter generator (HSG)

HSG bracket

Specification

Hybrid Starter Generator(HSG) Repair procedures

Inspection

Inspect the line to line resistanc

Hybrid Motor Control System

Hybrid Motor Control System

Description

The Hybrid Power Control Unit (HPCU), composed of various components, is

the core device among the Power Electronics

devices that acts as the brain.

It comprises of the Hybrid Control Unit (HCU), an inverter Motor Control

Un

Resolver Sensor Repair procedures | Motor Temperature Sensor Repair procedures

Resolver Sensor Repair procedures | Motor Temperature Sensor Repair procedures

Inspection

Hybrid Drive Motor

Inspect the resolver sensor resistance.

If the resolver sensor needs to be replaced, replace the hybrid drive motor assembly.

(Refer to Hybrid Motor Assembly - "Hybrid Drive M

SEE MORE:

Heater Core Repair procedures | Positive Temperature Coefficient (The PTC)

Heater Core Repair procedures | Positive Temperature Coefficient (The PTC)

Replacement

Disconnect the negative (-) battery terminal.

Remove the heater and blower assembly.

(Refer to Heater -"Heater Unit")

Loosen the mounting screws and remove heater core cover (A).

Pull out t

How to disconnect charging connector in emergency

How to disconnect charging connector in emergency

Before disconnecting the charging

connector, make sure the doors are

unlocked. When the door is locked,

the charging connector lock system

will not allow disconnection. To prevent

charging cable theft, the

charging connector cannot be

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us