KIA Niro: Gear Actuator Assembly, Repair procedures

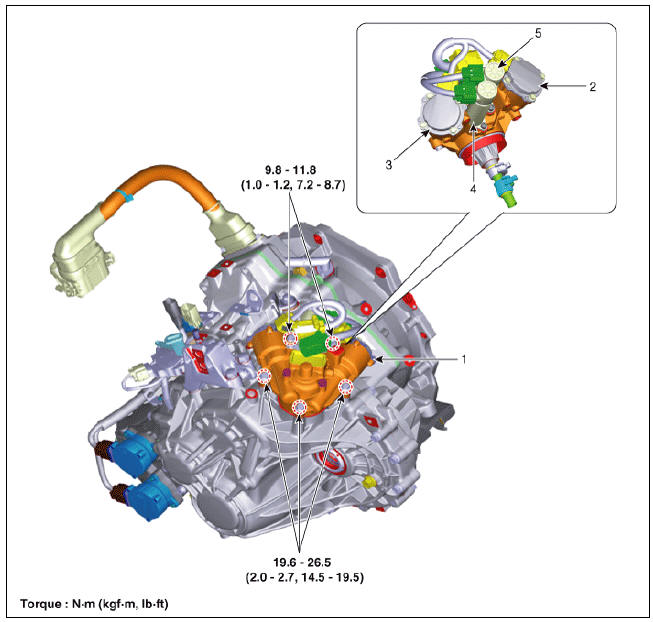

Component Location

- Gear actuator assembly

- Shift motor 2 (Even)

- Shift motor 1 (Odd)

- Select solenoid 2 (Even)

- Select solenoid 1 (Odd)

Specification

Gear Actuator Assembly Description and operation

Description

- The gear actuator comprises the shift motor and select solenoid.

- Gear actuator shift motor and select solenoid use signals from TCM to control the gear.

Schematic Diagrams

Gear Actuator Assembly Repair procedures

Removal

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to shut off the high voltage circuit according to the "High Voltage Shut-off Procedures" before doing any work related with the high voltage system to avoid serious electrical injuries.

- Shut off the high voltage circuit.

(Refer to Double Clutch Transmission System - "High Voltage Shut-off Procedure")

- Drain the coolant of hybrid cooling system.

(Refer to Hybrid Motor System - "Coolant")

- Remove the hybrid power control unit (HPCU) assembly.

(Refer to Hybrid Control System - "Hybrid Power Control Unit")

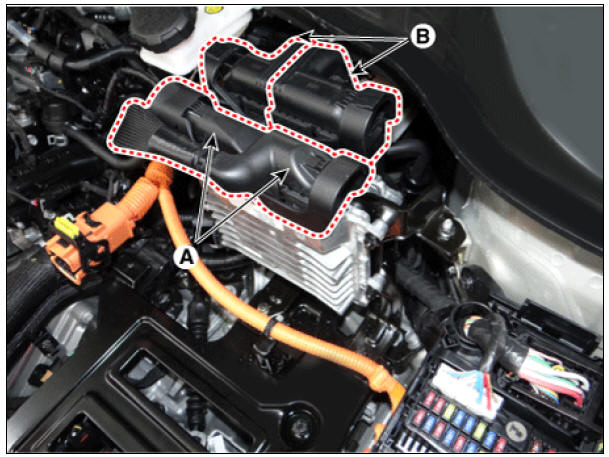

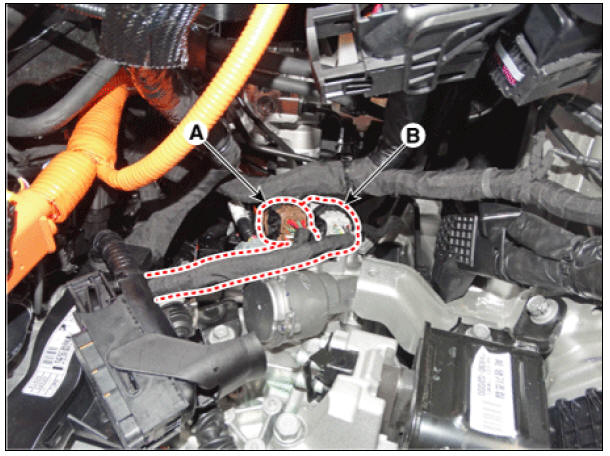

- Disconnect the TCM connector (A) and ECM connector (B).

- Remove the TCM (A) and ECM (B).

Tightening torque : 9.8 - 11.8 N*m (1.0 - 1.2 kgf*m, 7.2 - 8.7 lb*ft)

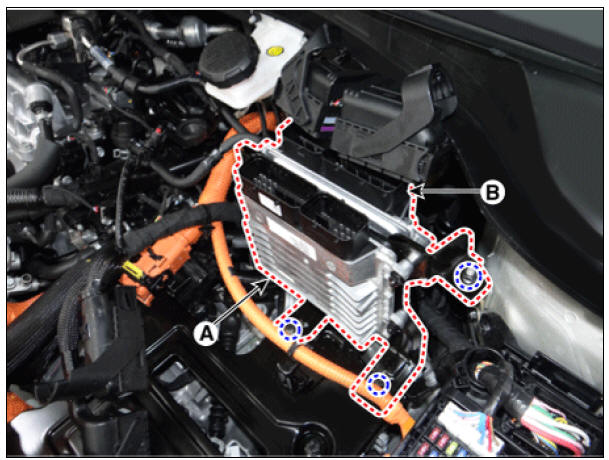

- Remove the HPCU tray (C) after removing the nut (A) and wiring mounting clips (B).

Tightening torque : (A) 10.8 - 13.7 N*m (1.1 - 1.4 kgf*m, 8.0 - 10.1 lb*ft) (C) 21.6 - 23.5 N*m (2.2 - 2.4 kgf*m, 15.9 - 17.4 lb*ft)

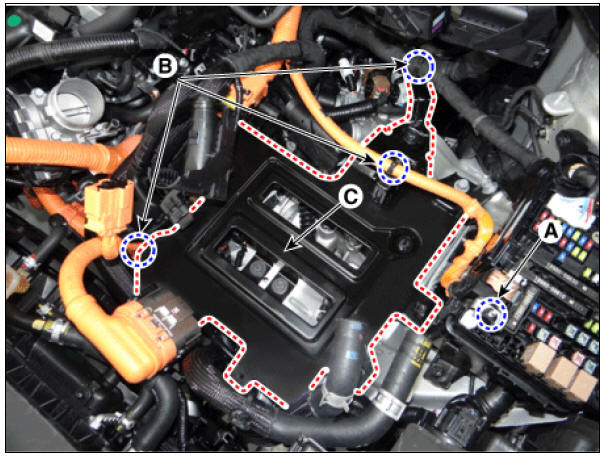

- Disconnect the gear actuator motor connector (A) and gear actuator solenoid connector (B).

- Remove the gear actuator assembly after loosening bolts (A, B).

Tightening torque :

(A) 19.6 - 26.5 N*m (2.0 - 2.7kgf*m, 14.5 - 19.5 lb*ft)

(B) 9.8 - 11.8 N*m (1.0 - 1.2kgf*m, 7.2 - 8.7 lb*ft)

Installation

- Install in the reverse order of removal.

Warning

Check the following before installing the gear actuator assembly.

1) Check that the gear actuator is placed in the "neutral" state.

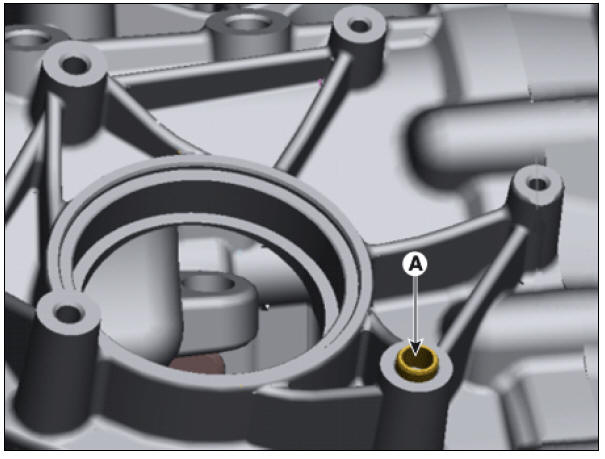

2) Check the assembled state of the O-rings (A).

3) Apply gear oil to the surface of O-rings.

4) Check the assembled state of the dowel pins (A).

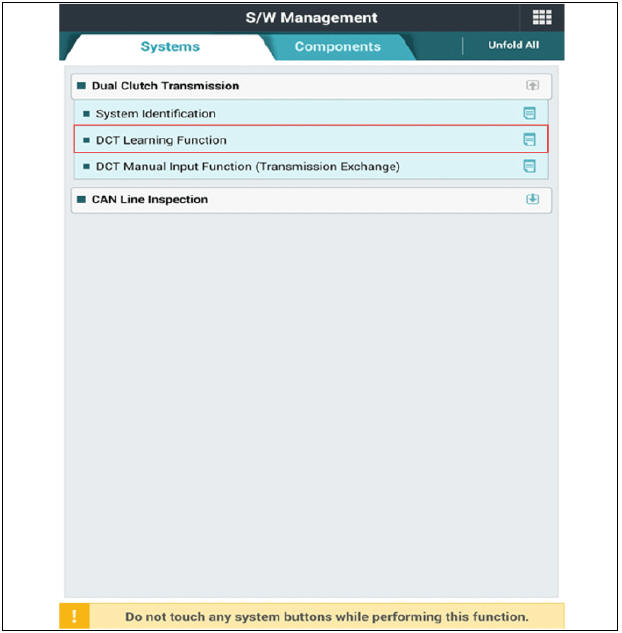

- Perform the clutch touch point learning procedure using the KDS after replacing the gear actuator assembly

READ NEXT:

Input speed sensor | Inhibitor Switch

Input speed sensor | Inhibitor Switch

Component Location

Input speed sensor

Specification

Input Speed Sensor Description and operation

Description

The input shaft speed sensor is important in that it detects the input shaft RPM and sends this information to the

SEE MORE:

Clutch Actuator Motor

Clutch Actuator Motor

Remove the under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

Remove the front wheel guard (LH).

(Refer to Body - "Front Wheel Guard")

Disconect the clutch actuator connector (A).

Motor

Opening the fuel filler door

Opening the fuel filler door

Fuel filler door

Fuel tank cap

Operation

Turn the engine off.

Ensure all the doors are unlocked.

Press the rear center edge to open the

fuel filler door (1).

Remove the fuel tank cap (2) by turning

it counterclockwise.

Pla

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us