KIA Niro: Engine Coolant Temperature Sensor (ECTS)

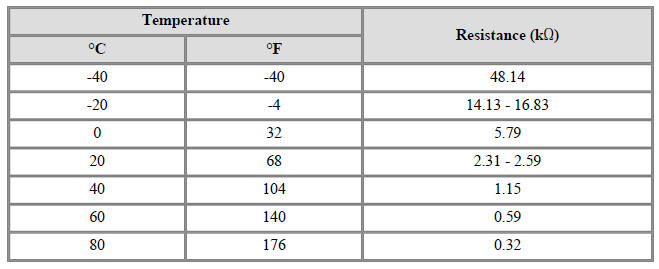

Specification

Description

Located in the engine coolant passage of the cylinder head, Engine Coolant

Temperature Sensor

(ECTS) detects the engine coolant temperature. The ECTS uses a thermistor with

resistance in

proportion to the temperature.

The electrical resistance of the ECTS decreases as the temperature increases,

and increases as the

temperature decreases. The reference +5V is supplied to the ECTS via a resistor

in the ECM. That is,

the resistor in the ECM and the thermistor in the ECTS are connected in series.

When the resistance

value of the thermistor in the ECTS changes according to the engine coolant

temperature, the output

voltage also changes.

During cold engine operation, the ECM increases the frequency of fuel injection

and controls the

ignition timing using the information of engine coolant temperature to avoid

engine stalling and

improve drivability.

Circuit

Diagram

ECTS (Water Temperature Control Assembly)

Harness Connector

ECTS (EGR Cooler Tube)

Harness Connector

Engine Coolant Temperature Sensor (ECTS) Repair procedures

Inspection

- Switch "OFF" the ignition.

- Remove the ECTS

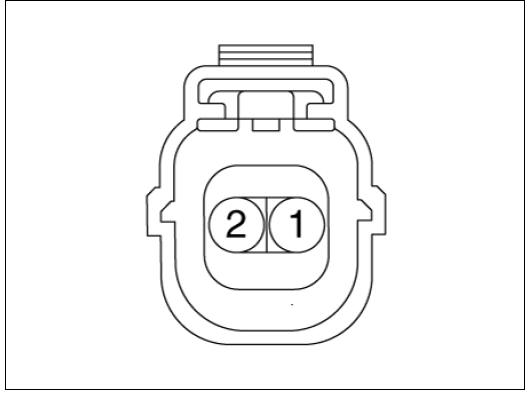

(Refer to "Removal"). - After immersing the thermistor of the sensor into engine coolant, measure resistance between the ECTS terminals 1 and 2.

- Check that the resistance is within the specification.

Removal

Engine Coolant Temperature Sensor (ECTS) (Water Temperature Control Assembly)

- Switch "OFF" the ignition and disconnect the negative (-) battery terminal.

- Remove the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

- Remove the purge control solenoid valve.

(Refer to Engine Control / Fuel System - "Purge Control Solenoid Valve (PCSV)")

- Disconnect the engine coolant temperature sensor connector (A).

- Remove the spring clip (B), and then pull the sensor from the water temperature control assembly.

Warning

Note that engine coolant may flow out from the water temperature

control assembly when

removing the sensor.

Engine Coolant Temperature Sensor (ECTS) (EGR Cooler Tube)

- Switch "OFF" the ignition and disconnect the negative (-) battery terminal.

- Remove the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

- Disconnect the engine coolant temperature sensor connector (A).

- Remove the spring clip (B), and then pull the sensor from the water temperature control assembly.

Warning

Note that engine coolant may flow out from the water temperature

control assembly when

removing the sensor.

Installation

Warning

- Install the component to the specified torque.

- Note that internal damage may occur when the component is dropped. If the component has been dropped, inspect before installing.

- Apply the engine coolant to the O-ring.

- Insert the sensor in the installation hole and be careful not to damage it.

- Install in the reverse order of removal.

- Replenish the engine coolant.

(Refer to Engine Mechanical System - "Coolant")

READ NEXT:

Crankshaft Position Sensor (CKPS)

Crankshaft Position Sensor (CKPS)

Specification

Crankshaft Position Sensor (CKPS) Description and operation

Description

Crankshaft Position Sensor (CKPS) is one of the most important sensors of the

engine control system

that detects the crankshaft position. Lack of CKPS sig

Camshaft Position Sensor (CMPS)

Camshaft Position Sensor (CMPS)

Description

Camshaft Position Sensor (CMPS) is a hall sensor, which detects the camshaft

position by using a hall

element.

It is related with Crankshaft Position Sensor (CKPS) and detects the piston

position of each cylinder

which cannot be

Knock Sensor (KS)

Knock Sensor (KS)

Specification

Knock Sensor (KS) Description and operation

Description

Knocking is a phenomenon characterized by undesirable vibration and noise

that can cause engine

damage. Knock Sensor (KS) is installed on the cylinder block and senses en

SEE MORE:

Mass Air Flow Sensor (MAFS)

Mass Air Flow Sensor (MAFS)

Description

MAFS uses a sensing element made of a hot-film to measure the mass of intake

air entering the engine

and to send the signal to the ECM.

A large amount of intake air represents acceleration or high load conditions

while a small am

Battery Temperature Sensor

Battery Temperature Sensor

Specification

Air Inlet Temperature Sensor

Battery Temperature Sensor (Side of cell)

Description

Battery Temperature Sensor is installed inside the high voltage battery pack

assembly. It measures the temperature of t

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us