KIA Niro: Drive Belt Tensioner Repair procedures

Removal and

Installation

- Remove the drive belt.

(Refer to Drive Belt System - "Drive Belt")

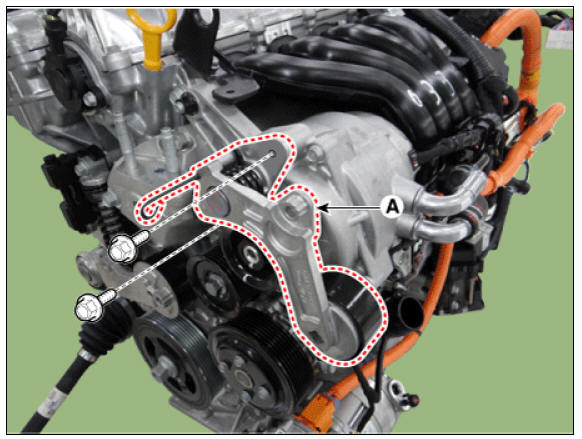

- Remove the mechanical tensioner (A).

Tightening torque : 18.6 - 23.5 N*m (1.9 - 2.4 kgf*m, 13.7 - 17.4 lb*ft)

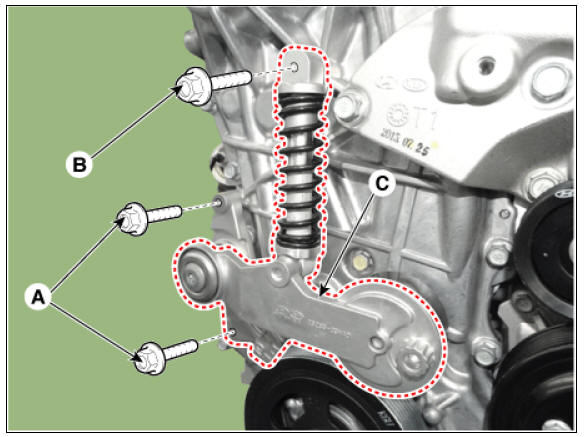

- Remove the hydraulic tensioner.

(1) Check that the hydraulic tensioner spring is compressed.

(2) Unfasten the hydraulic tensioner mounting bolt (A).

(3) Unfasten the hydraulic tensioner center bolt (B).

(4) Remove the hydraulic tensioner mounting bolt (A).

(5) Remove the hydraulic tensioner (C).

Tightening torque : 27.5 - 31.4 N*m (2.8 - 3.2 kgf*m, 20.3 - 23.1 lb*ft)

- Install in the reverse order of removal.

Inspection

Check the belt tensioner for excessive dust, crack, and damage. Replace if necessary.

Crankshaft Damper Pulley Repair procedures

Removal and

Installation

- Remove the RH front wheel.

(Refer to Suspension System - "Wheel")

- Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

- Remove the drive belt.

(Refer to Drive Belt System - "Drive Belt")

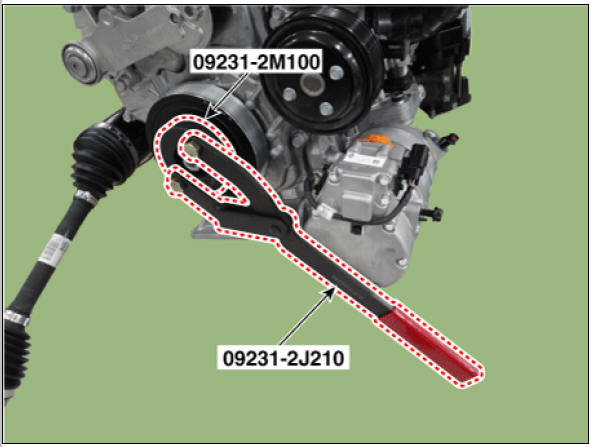

- Remove the crankshaft damper pulley (A).

Tightening torque : (64.7 - 71.6 N*m (6.6 - 7.3 kgf*m, 47.7 - 52.8 Ib*ft)) + (39 - 41º)

Warning

Using the SST (09231-2M100, 09231-2J210) to hold the crankshaft

damper pulley.

- Install in the reverse order of removal.

READ NEXT:

Engine And Transaxle Assembly

Engine And Transaxle Assembly

Engine Room Under Cover Repair procedures

Removal

Engine room under cover.

Remove the engine room under cover (A).

Tightening torque :

3.9 - 5.9 N*m (0.4 - 0.6 kgf*m, 2.9 - 4.3 lb*ft)

Install in the reverse order of removal.

Engine Mounting Repair Procedures

Engine Mounting Repair Procedures

Engine Mounting Components and components location

Transaxle mounting bracket

Roll rod bracket

Engine mounting bracket

Engine mounting support bracket

Engine Mounting Repair Procedures

Removal and

Installation

Engine Mounting Brac

Engine And Transaxle Assembly Repair procedures

Engine And Transaxle Assembly Repair procedures

Removal

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any work related with

the high voltage system. Failure to follow the safety instructions may

result in serious electrical injuries.

Be

SEE MORE:

Cell Monitoring Unit (CMU) Terminal And Input/Output

Signal

Cell Monitoring Unit (CMU) Terminal And Input/Output

Signal

System Configuration

Connector Type

Terminal Function

Cell Monitoring Unit (CMU) #1 (Sub Voltage Battery Pack Assembly)

Connector (B01-A) (16Pin) : High Voltage Battery control

Connector (B01-C) (12Pin) : High Voltage Battery Cel

Memory Power Seat Unit

Memory Power Seat Unit

Memory power seat unit Components and components location

Connector Pin Information

Memory power seat unit Repair procedures

Removal

Before removing the driver side seat assembly, pull it upward to the

maximum by pushing the fro

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us