KIA Niro: Engine Mounting Repair Procedures

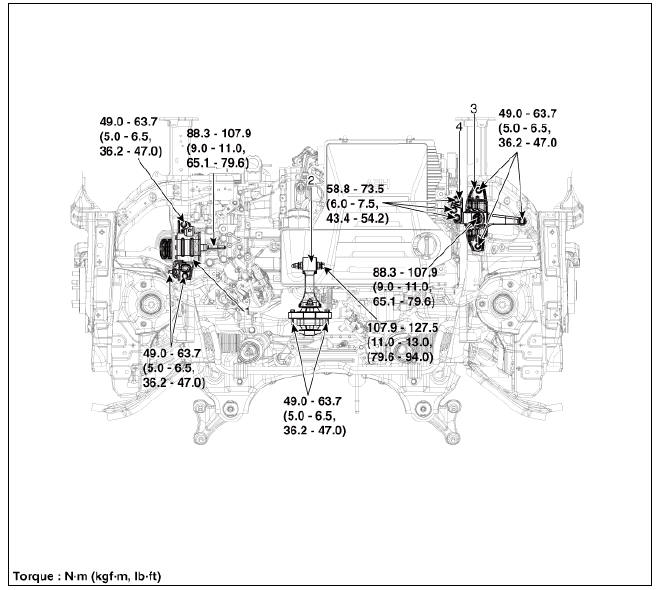

Engine Mounting Components and components location

- Transaxle mounting bracket

- Roll rod bracket

- Engine mounting bracket

- Engine mounting support bracket

Engine Mounting Repair Procedures

Removal and

Installation

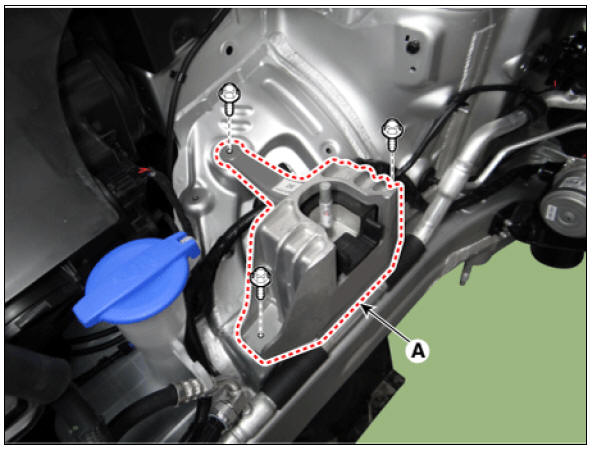

Engine Mounting Bracket

- Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

- Install the jack to the edge of upper oil pan to support the engine.

Warning

Put a rubber block between the jack and oil pan to avoid damaging the oil pan.

- Remove the engine mounting support bracket (A).

Tightening torque

Nut (B) :

88.3 - 107.9 N*m (9.0 - 11.0 kgf*m, 65.1 - 79.6 lb*ft)

Bolt (C) and nuts (D) :

58.8 - 73.5 N*m (6.0 - 7.5 kgf*m, 43.3 - 54.2 lb*ft)

Warning

Do not reuse the bolt C, which is special bolt coated with bond.

- Remove the reservoir tank.

(Refer to Cooling System - "Reservoir Tank")

- Remove the engine mounting bracket (A).

Tightening torque : 49.0 - 63.7 N*m (5.0 - 6.5 kgf*m, 36.2 - 47.0 lb*ft)

- Install in the reverse order of removal.

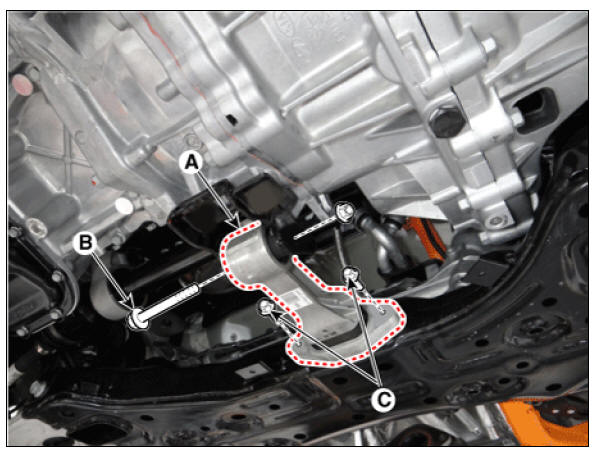

Roll Rod Bracket

- Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

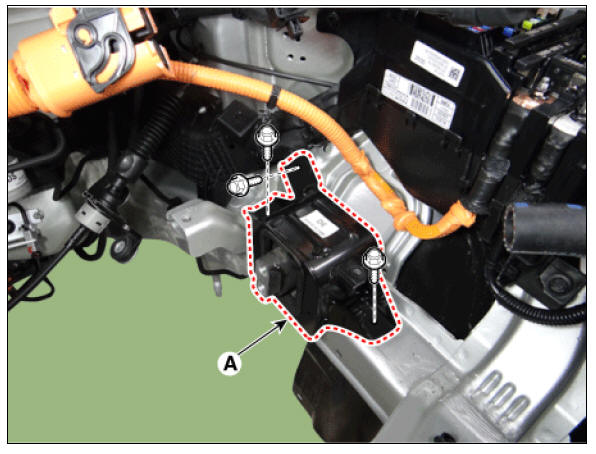

- Remove the roll rod bracket (A).

Tightening torque :

Bolt (B) :

107.9 - 127.5 N*m (11.0 - 13.0 kgf*m, 79.6 - 94.0 lb*ft)

Bolts (C) :

49.0 - 63.7 N*m (5.0 - 6.5 kgf*m, 36.2 - 47.0 lb*ft)

- Install in the reverse order of removal.

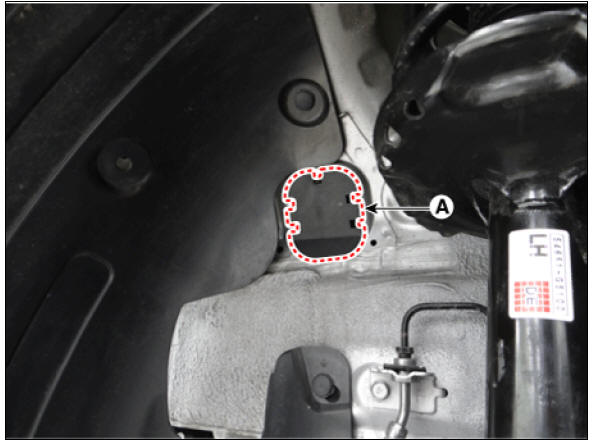

Transaxle Mounting Bracket

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to shut off the high voltage circuit according to the "High Voltage Shut-off Procedures" before doing any work related with the high voltage system to avoid serious electrical injuries.

- Shut off the high voltage circuit.

(Refer to Engine Mechanical System - "High Voltage Shut off Procedure")

- Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

- Drain the inverter coolant.

(Refer to Hybrid Motor System - "Coolant")

- Remove the air cleaner assembly.

(Refer to Intake and Exhaust System - "Air Cleaner")

- Remove the hybrid power control unit (HPCU) and tray.

(Refer to Hybrid Control System - "Hybrid Power Control Unit (HPCU)")

- Remove the Engine Control Module (ECM).

(Refer to Engine Control/Fuel System - "Engine Control Module (ECM)")

- Install the jack to the edge of transaxle.

- Remove the transaxle mounting side panel packing (A).

- Remove the transaxle mounting bolt (A).

Tightening torque : 88.3 - 107.9 N*m (9.0 - 11.0 kgf*m, 65.1 - 79.6 lb*ft)

- Remove the transaxle mounting bracket (B).

Tightening torque : 49.0 - 63.7 N*m (5.0 - 6.5 kgf*m, 36.2 - 47.0 lb*ft)

- Install in the reverse order of removal.

READ NEXT:

Engine And Transaxle Assembly Repair procedures

Engine And Transaxle Assembly Repair procedures

Removal

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any work related with

the high voltage system. Failure to follow the safety instructions may

result in serious electrical injuries.

Be

Air Cleaner Repair procedures

Air Cleaner Repair procedures

Removal and

Installation

Air Cleaner Assembly

Disconnect the air duct B (A).

Tightening torque :

2.9 - 4.9 N*m (0.3 - 0.5 kgf*m, 2.2 - 3.6 lb*ft)

Disconnect the mass air flow sensor (MAFS) connector (A) and breather

hose (B).

SEE MORE:

Remote Operation

Remote Operation

Operating order

Remote Operation operates in the following

order:

Getting ready to remotely move forward

and backward

Remotely moving forward and backward

1. Getting ready to remotely move forward and backward

There are two ways t

Securing a Child Restraint System

with the "ISOFIX Anchorage" system

Securing a Child Restraint System

with the "ISOFIX Anchorage" system

ISOFIX anchorages are metal bars built

into the vehicle. There are two lower

anchors for each ISOFIX seating position

that will accommodate a Child Restraint

System with lower attachments.

ISOFIX anchor position indicator

ISOFIX anchor

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us