KIA Niro: Cylinder Block Repair procedures

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to shut off the high voltage circuit according to the "High Voltage Shut-off Procedures" before doing any work related with the high voltage system to avoid serious electrical injuries

Warning

Turn the crankshaft pulley so that the No.1 piston is at TDC (Top dead center).

Use fender covers to avoid damaging painted surfaces.

To avoid damaging the cylinder head, wait until the engine coolant temperature drops below normal temperature before removing it.

When handling a metal gasket, be careful not to fold the gasket or damage the contacting surface of the gasket.

To avoid damage, unplug the wiring connectors carefully while holding the connector portion.

Warning

Mark all wiring and hoses to avoid misconnection.

- Shut off the high voltage circuit.

(Refer to Engine Mechanical System - "High Voltage Shut off Procedure")

- Remove the engine assembly from the vehicle.

(Refer to Engine and Transaxle Assembly - "Engine and Transaxle Assembly")

- Remove the dual clutch transmission.

(Refer to Double Clutch Transmission (DCT) - "Double Clutch Transmission Assembly")

- Install the engine to engine stand for disassembly.

- Remove the intake manifold.

(Refer to Intake and Exhaust System - "Intake Manifold")

- Remove the exhaust manifold.

(Refer to Intake and Exhaust System - "Exhaust Manifold")

- Remove the hybrid starter generator (HSG).

(Refer to Hybrid Motor System - "Hybrid Starter Generator (HSG)")

- Remove the timing chain.

(Refer to Timing System - "Timing Chain")

- Remove the Cylinder head assembly.

(Refer to Cylinder Head Assembly - "Cylinder Head")

- Remove the fly wheel.

(Refer to Cylinder Block - "Fly Wheel")

- Remove the thermostat.

(Refer to Cooling System - "Thermostat")

- Remove the water pump assembly.

(Refer to Cooling System - "Water Pump")

- Remove the A/C compressor.

(Refer to Heating, Ventilation Air conditioning -"Compressor")

- Remove the oil filter.

(Refer to Lubrication System - "Engine Oil")

- Remove the oil screen.

(Refer to Lubrication System - "Oil Pan")

- Remove the piston and connecting rod assemblies.

(Refer to Cylinder Block -"Piston and Connecting")

- Remove the Crankshaft.

(Refer to Cylinder Block -"Crankshaft")

- Remove the knock sensor.

(Refer to Engine Control / Fuel System - "Knock Sensor")

- Remove the crankshaft position sensor (CKPS).

(Refer to Engine Control / Fuel System - "Crankshaft Position Sensor (CKPS)")

- Remove the oil pressure switch.

(Refer to Lubrication System - "Oil Pressure Switch")

- Remove the water jacket insert.

(Refer to Cylinder Block - "Water Jacket Insert")

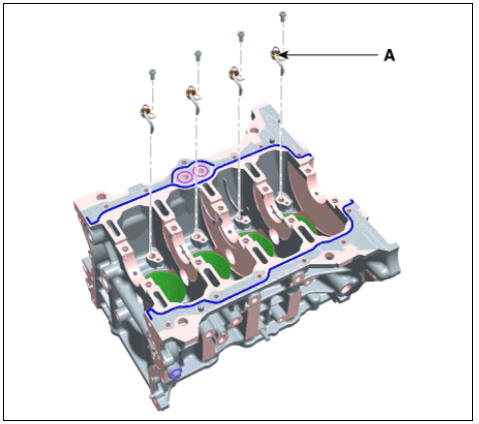

- Remove the piston cooling oil jet (A).

Inspection

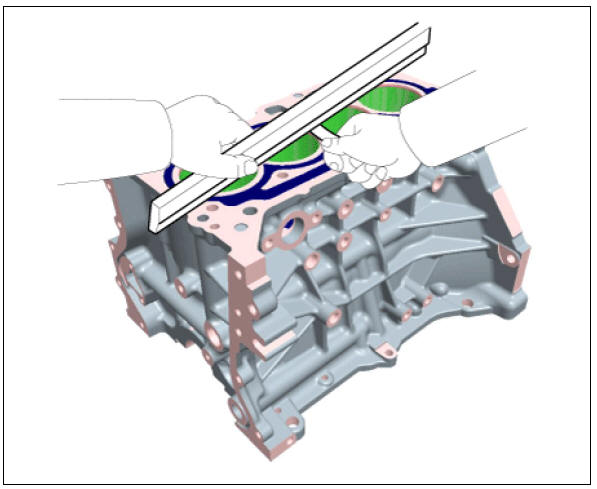

- Remove gasket material.

Using a gasket scraper, remove all the gasket material from the top surface of the cylinder block.

- Clean cylinder block Using a soft brush and solvent, thoroughly clean the cylinder block.

- Inspect top surface of cylinder block for flatness.

Using a precision straight edge and feeler gauge, measure the surface contacting the cylinder head gasket for warpage.

Flatness of cylinder block gasket surface :

Standard :

Less than 0.05 mm (0.0020 in.) for total area

Less than 0.02 mm (0.0008 in.) for a section of 100 mm (3.9370 in.) X 100 mm (3.9370 in.)

- Inspect the cylinder bor

Visually check the cylinder for vertical scratches.

If deep scratches are present, replace the cylinder block.

- Inspect the cylinder bore diameter.

Using a cylinder bore gauge, measure the cylinder bore diameter at position in the thrust and axial direction.

Cylinder bore diameter : 72.00 - 72.03 mm (2.8346 - 2.8358 in.)

Warning

Measure at 5mm (0.1969 in.) / 71.5mm (2.8150 in.) / 132.5mm (5.2165 in.) from the top of cylinder block.

- Check the cylinder bore size code on the cylinder block side surface.

Cylinder Bore Inner Diameter

Reassembly

- Install the piston cooling oil jet (A).

Tightening torque : 8.8 - 10.8 N*m (0.9 - 1.1 kgf*m, 6.5 - 8.0 lb*ft)

- Assemble the remaining parts in the reverse order of disassembly.

Warning

In case the cylinder block is replaced with a new one, select the proper crankshaft main bearing and the piston according to the crankshaft journal bore mark and the cylinder bore mark on the cylinder block.

- Crankshaft main bearing selection (Refer to Cylinder Block - "Crankshaft")

- Piston selection (Refer to Cylinder Block - "Piston and Connecting Rod")

READ NEXT:

Cylinder Head Cover Components and components location | Cylinder Head Cover Repair procedures

Cylinder Head Cover Components and components location | Cylinder Head Cover Repair procedures

Components

Camshaft bearing cap

Camshaft front bearing cap

Exhaust camshaft

Intake camshaft

Exhaust CVVT assembly

Intake CVVT assembly

Cylinder head

Cylinder head gasket

Retainer lock

Retainer

SEE MORE:

Fuel Pump Repair procedures

Fuel Pump Repair procedures

Fuel sender

Turn the ignition switch OFF, and then remove battery (-) terminal.

Remove the fuel pump assembly.

Using an ohmmeter, measure the resistance between terminals 1 and 6 of

sender connector (A) at

each float level.

Battery Tester - The MDX-670P Analyzer

Battery Tester - The MDX-670P Analyzer

The MDX-670P battery conductance and electrical system analyzer tests

batteries as well as starting and charging

systems for vehicle.

It displays the test results in seconds and features a built-in printer to

provide a copy of the results.

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us