KIA Niro: Battery Tester - The MDX-670P Analyzer

The MDX-670P battery conductance and electrical system analyzer tests batteries as well as starting and charging systems for vehicle.

It displays the test results in seconds and features a built-in printer to provide a copy of the results.

Warning

1) Because of the possibility of personal injury, always use extreme caution and appropriate eye protection when working with batteries.

2) When charging battery by test result, Battery must be fully

charged. To get accurate test result, battery

surface voltage must have subsided ahead before test when you test battery after

charged. (See following

Battery Test Results)

Warning

When testing the vehicle with old diesel engines, the test result will not be favorable if the glow plug is not heated. Conduct the test after warming up the engine for 5 minutes.

- Connect the red clamp to the positive (+) terminal and the black clamp to the negative (-) terminal.

Warning

For a proper connection, rock the clamps back and forth. The tester

requires that both sides of each clamp be

firmly connected before testing. A poor connection will produce a CHECK

CONNECTION or WIGGLE

CLAMPS message. If the message appears, clean the terminals and reconnect the

clamps.

- Scroll to and select IN VEHICLE or OUT OF VEHICLE for a battery not connected to a vehicle.

Warning

Following an IN VEHICLE test you will be prompted to test the starting and charging systems.

- Scroll to and select REGULAR FLOODED, AGM FLAT PLATE, or AGM SPIRAL where applicable.

Warning

If the vehicle equipped with ISG function, select the AGM FLAT PLATE.

- Scroll to and select the battery's rating system.

Warning

Mostly, the CCA value is marked on the battery label, but sometimes marked EN or SEA value. Select one of them.

- CCA: Cold Cranking Amps, as specified by SAE. The most common rating for cranking batteries at 0 ºF (- 17.8 ºC).

- EN: Europe-Norm

- SAE: Society of Automotive Engineers, the European labeling of CCA

- Set the selected rating value displayed on the screen to the value marked on the battery label by pressing up and down arrow buttons.

- Press ENTER to start test.

- After several seconds the tester displays the decision on the battery's condition and the measured voltage. The tester also displays your selected battery rating and the rating units.

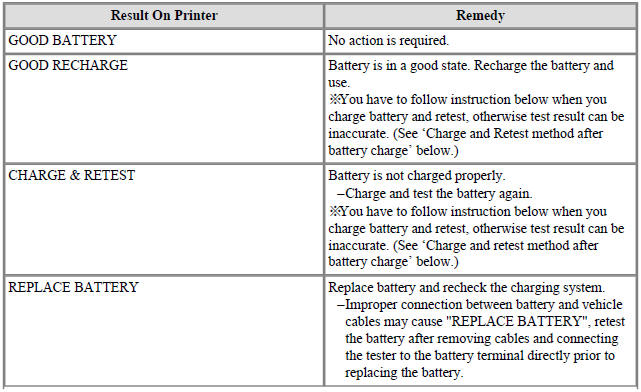

Battery Test Results

Charge and Retest method after battery charge

Battery charge

Set battery charger to 'Auto Mode' (The Mode that charging current drops as

the battery charges.) and charge

battery until charging current down close to zero or the charger alerts you with

an alarm when charge is

complete.(Minimum charging time recommended: More than 3 hours with Auto Mode

that explained above)

- If battery is not fully charged, battery surface voltage will be high while the amount of current charged (CCA) in battery is low. If you measure the battery under this condition, tester may misjudge that battery sulfation occurred because the amount of current in battery is too low in comparison with battery voltage.

Surface voltage: When battery is charged electrolyte temperature increases and chemical reaction become active resulting in an excessive increase of battery voltage.

It is known that it takes approximate one day to subside this increased surface voltage completely.

Battery Test after charge

Do not test battery right after the charge. Test battery after battery surface voltage has subsided as instructed in the following procedure.

(1) When battery charge is complete, install the battery in the vehicle.

(2) Put IG key to ON position and turn on head lamp with low beam, and wait 5 minutes. (Discharge for 5 minutes)

(3) Turn off the head lamp and IG key, and wait 5 minutes. (Waiting for 5 minutes)

(4) Remove +, - cable from the battery and test battery.

Warning

For an in-vehicle test, the display alternates between the test results and the message "PRESS FOR STARTER TEST.

Warning

Before starting the test, inspect the alternator drive belt. A belt that is glazed or worn, or lacks the proper tension, will prevent the en¬gine from achieving the rpm levels needed for the test.

- Press the ENTER button to proceed with the starter test.

- Start the engine when prompted.

- The tester displays the decision on the starter system, cranking voltage, and cranking time in milliseconds.

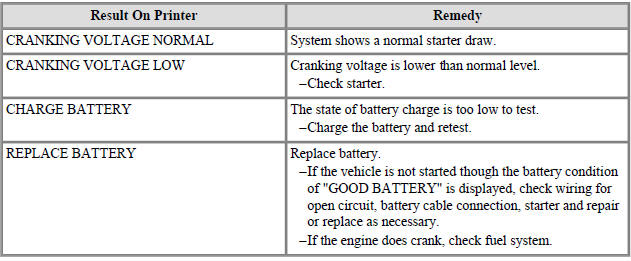

Starter Test Results

Warning

For an in-vehicle test, the display alternates between the test results and the message "PRESS FOR CHARGING TEST.

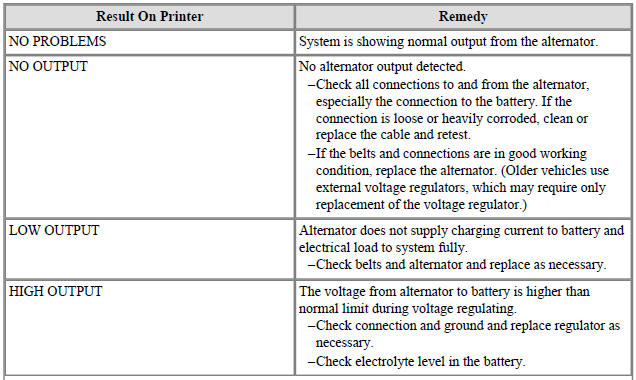

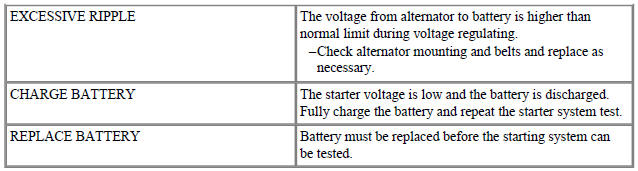

Step 3: Charging System Test

- Press the ENTER button to proceed with the charging test.

- Rev the engine with loads off. (Following the on-screen prompts)

- The message that engine RPM is detected will be displayed on the screen, idle the engine.

- Turn on electrical loads (air conditioner, lamps, audio and etc). Press ENTER to continue.

- Turn on electrical loads (air conditioner, lamps, audio and etc). Press ENTER to continue.

- The message that engine RPM is detected will be displayed on the screen, idle the engine.

- Turn off loads and engine.

- The Charging System decision is displayed at the end of the procedure.

- Press the BACK/PRINT button to print the test results or MENU to return to the Options Menu.

Installation

- Install in the reverse order of removal.

Warning

When installing the battery, fix the mounting bracket on the tray correctly.

Warning

After disconnecting then reconnecting the battery negative cable, reset some parts that require the reset procedures.

(Refer to Body Electrical System - "General Information")

READ NEXT:

Cleaning

Cleaning

Make sure the ignition switch and all accessories are in the OFF

position.

Remove the battery from the vehicle.

(Refer to Charging System - "Battery")

Warning

Care should be taken in the event the battery case is cracked or

Battery Sensor Repair procedures

Battery Sensor Repair procedures

Removal

Open the trunk.

Remove the luggage side trim (RH) side cover (A).

Turn the ignition switch OFF and disconnect the battery negative (-)

terminal (A).

Disconnect the battery sensor connector (B).

Battery (-) terminal tig

Ignition System

Ignition System

Description

Ignition timing is controlled by the electronic control ignition timing

system. The standard reference

ignition timing data for the engine operating conditions are preprogrammed in

the memory of the ECM

(Engine Control Module).

SEE MORE:

Rear Seat Cushion Cover | Rear Back Armrest

Rear Seat Cushion Cover | Rear Back Armrest

Rear seat cushion cover

Replacement

Remove the seat assembly.

(Refer to Rear Seat - "Rear Seat Assembly")

Remove the rear seat cushion cover (A) after removing the hog-ring clips on the rear of seat cushi

Seat belts

Seat belts

Seat belts are designed to bear upon the

bony structure of the body, and should

be worn low across the front of the pelvis,

chest and shoulders.

WARNING

For maximum restraint system protection,

the seat belts must always be

used whenever

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us