KIA Niro: CVVT Oil Control Valve (OCV)

Specification

Bank 1 / Exhaust

Description

Continuous Variable Valve Timing (CVVT) system advances or retards the valve

timing of the intake

and exhaust valve in accordance with the ECM control signal which is calculated

by the engine speed

and load.

By controlling CVVT, the valve overlap or underlap occurs, which in turn

improves fuel efficiency,

reduces exhaust gases (NOx, HC) and improves engine performance by reducing

pumping loss,

generating internal EGR effect, improving combustion stability, improving

volumetric efficiency and

increasing expansion work.

This system consists of

- the CVVT Oil Control Valve (OCV) which supplies the engine oil to the

cam phaser or cuts the

engine oil from the cam phaser in accordance with the ECM PWM (Pulse With Modulation) control

signal, - the CVVT Oil Temperature Sensor (OTS) which measures the engine oil temperature,

- and the Cam Phaser which varies the cam phase by using the hydraulic force of the engine oil.

The engine oil released from the CVVT oil control valve varies the cam phase

in the direction (Intake

Advance/Exhaust Retard) or opposite direction (Intake Retard/Exhaust Advance) of

the engine rotation

by rotating the rotor connected with the camshaft inside the cam phaser.

Bank1 / Intake

Bank 1 / Exhaust

Circuit Diagram

Harness Connector

OCV (B1/EX)

Inspection

- Switch "OFF" the ignition.

- Disconnect the OCV connector.

- Measure resistance between the OCV terminals 1 and 2.

- Check that the resistance is within the specification.

Specification: 9.4 ~ 10.4 Ω (20ºC(68ºF))

CVVT Oil Control Valve (OCV) Repair procedures

Removal

CVVT Oil Control Valve

CVVT Oil Control Valve (Intake)

- Switch "OFF" the ignition and disconnect the negative (-) battery terminal.

- Remove the variable force solenoid.

(Refer to Engine Control System - " Variable Force Solenoid")

- Remove the cylinder head cover.

(Refer to Engine Mechanical System - "Cylinder Head Cover")

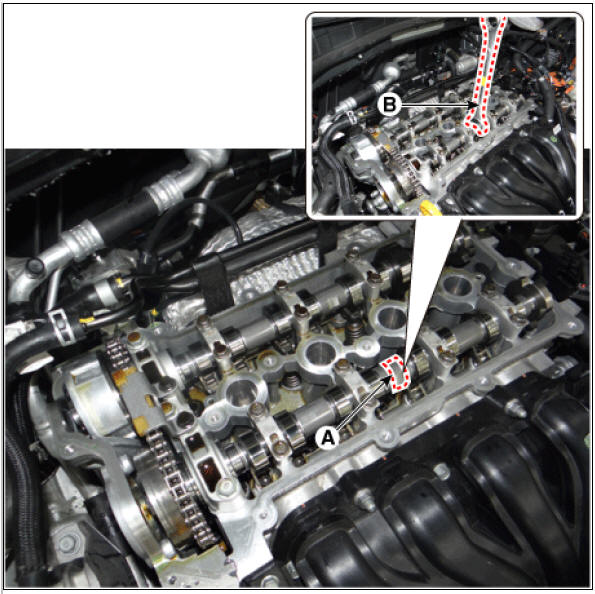

- Remove the CVVT oil control valve (A) using a socket & wrench (B).

CVVT oil control valve center bolt : (47.1 - 52.0 N.m (4.8 - 5.3 kgf.m, 34.7 - 38.3 lb-ft)) + (25 - 31º)

Warning

- To prevent impurities from entering intake OCV & center bolt, wear rubber gloves.

- When removing the intake OCV & center bolt, place a wrench (B)

at position (A) to prevent the

camshaft from rotating.

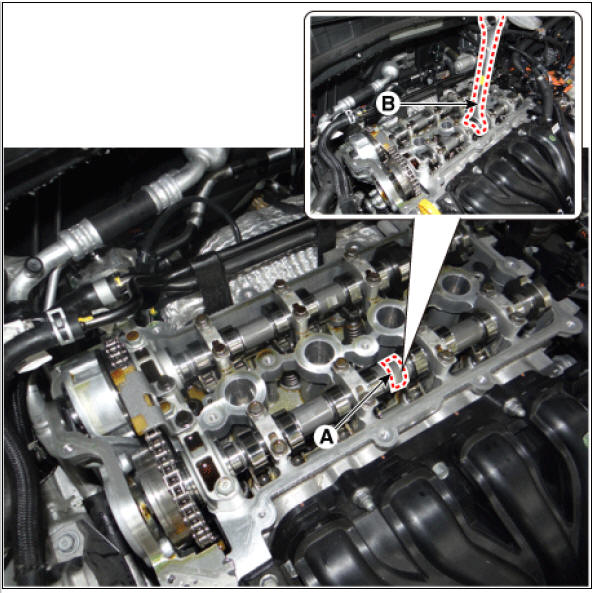

CVVT Oil Control Valve (Exhaust)

- Switch "OFF" the ignition and disconnect the negative (-) battery terminal.

- Remove the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

- OCV connector (A).

- Remove the mounting bolt, and then remove oil control valve from the engine.

CVVT oil control valve mounting bolt : 9.8 - 11.8 N*m (1.0 - 1.2 kgf*m, 7.2 - 8.7 lb*ft)

Installation

Warning

- Install the component to the specified torque.

- Note that internal damage may occur when the component is dropped. If the component has been dropped, inspect before installing.

- Apply engine oil to the valve O-ring.

- To prevent impurities from entering intake OCV & center bolt, wear rubber gloves.

- When installing the intake OCV & center bolt, place a wrench

(B) at position (A) to prevent the

camshaft from rotating.

- Install in the reverse order of removal.

READ NEXT:

Fuel Pressure Control Valve (FPCV)

Fuel Pressure Control Valve (FPCV)

Specification

Fuel Pressure Control Valve (FPCV) Description

Description

Installed on the high pressure fuel pump, the Fuel Pressure Control Valve

controls the flow of fuel into

the injectors in accordance with the ECM signal calculated ba

Electric EGR Control Valve

Electric EGR Control Valve

Specification

Motor

Position sensor

Electric EGR Control Valve Description and operation

Description

The Electric EGR Control Valve is a solenoid valve installed between the EGR

cooler and the exhaust

line that controls the EGR (Exhaust

Fuel Delivery System

Fuel Delivery System

Components

Location

Fuel Tank Assembly

Fuel tank

Fuel pump

Fuel filter

Fuel pressure regulator

Canister

Fuel tank air Filter

Fuel pressure sensor (FPS)

Fuel tank pressure sensor (FTPS)

Fuel level sensor (FLS)

Fuel tank iso

SEE MORE:

Lane Keeping Assist (LKA)

Lane Keeping Assist (LKA)

Lane Keeping Assist is designed to help

detect lane markings (or road edges)

while driving over a certain speed. Lane

Keeping Assist will warn the driver if the

vehicle leaves the lane without using the

turn signal, or will automatically ass

Smart Key Repair procedures, Smart Key Unit

Smart Key Repair procedures, Smart Key Unit

Adjustment

Smart Key Code Saving

Connect the VCI II in driver side crash pad lower panel, turn the power on KDS.

Select the vehicle model and then do "Smart key code saving".

After selecting "Smart Key Code

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us