KIA Niro: CVVT & Camshaft Description and operation

Description

Continuous Variable Valve Timing (CVVT) system advances or retards the valve timing of the intake and exhaust valve in accordance with the ECM control signal which is calculated by the engine speed and load.

By controlling CVVT, the valve over-lap or under-lap occurs, which makes better fuel economy, reduces exhaust gases (NOx, HC) and improves engine performance through reduction of pumping loss, internal EGR effect, improvement of combustion stability, improvement of volumetric efficiency, and increased expansion work.

This system consists of

- the CVVT Oil Control Valve (OCV) which supplies the engine oil to the

cam phaser or runs out the engine oil from the cam phaser in accordance with

the ECM

PWM (Pulse With Modulation) control signal, - the CVVT Oil Temperature Sensor (OTS) which measures the engine oil temperature,

- and the Cam Phaser which varies the cam phase by using the hydraulic force of the engine oil.

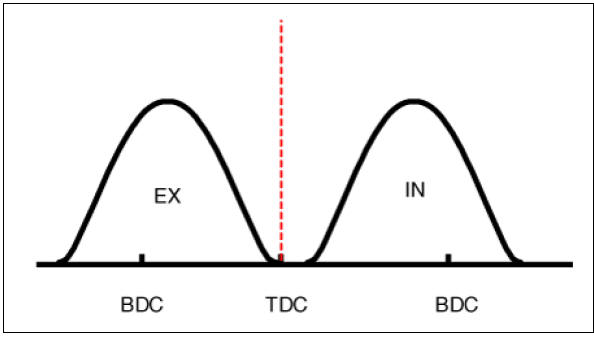

The engine oil released from the CVVT oil control valve varies the cam phase

in the direction (Intake Advance/Exhaust Retard) or opposite direction (Intake

Retard/

Exhaust Advance) of the engine rotation by rotating the rotor connected with the

camshaft inside the cam phaser.

Operation Principle

The CVVT has the mechanism of rotating the rotor vane with hydraulic force

generated by the engine oil supplied to the advance or retard chamber in

accordance with

the CVVT oil control valve control.

- Intake CVVT

- Exhaust CVVT

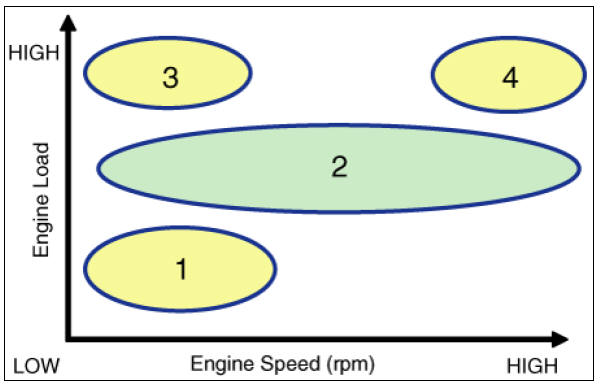

CVVT System Mode

- Low Speed / Low Load

- Partial Load

- Low Speed / High Load

- High Speed / High Load

READ NEXT:

CVVT & Camshaft Repair procedures

CVVT & Camshaft Repair procedures

Removal

Warning

Use fender covers to avoid damaging painted surfaces.

To avoid damaging the cylinder head, wait until the engine

coolant temperature drops below normal

temperature (20ºC (68ºF)) before removing it.

When handling a meta

Cylinder Head Repair procedures

Cylinder Head Repair procedures

Removal

Engine removal is not required for this procedure.

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any work related

with the high voltage system. Failure to follow the safety instruction

Cylinder Head

Cylinder Head

Inspect for flatness.

Using a precision straight edge and feeler gauge, measure the contacting

surface of the cylinder block and check

the manifolds for warpage.

If the flatness is greater than maximum, replace the cylinder head.

Fla

SEE MORE:

Tailgate Assembly

Tailgate Assembly

Tailgate / Repair Procedures

Adjustment

After loosening the tailgate hinge (A) mounting

bolts, adjust the tailgate by moving it up and down, or right and left.

Adjust the tailgate height by turning the tailgate

overslam bumpers (B).

Af

Memory Power Seat Switch

Memory Power Seat Switch

Connector and Terminal Function

Memory power seat switch Repair procedures

Removal

Disconnect the negative (-) battery terminal.

Remove the driver front door trim.

(Refer to Body - "Front Door Trim")

Remove the memory power

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us