KIA Niro: Coolant Repair procedures

Refilling And Bleeding

Warning

Never remove the cap when the engine is hot. Serious scalding could be caused by hot fluid under high pressure escaping from the reservoir.

Warning

When pouring inverter coolant, be sure to shut the relay box lid to prevent spilling coolant onto electrical parts or painted surfaces. Immediately rinse off any spilt coolant.

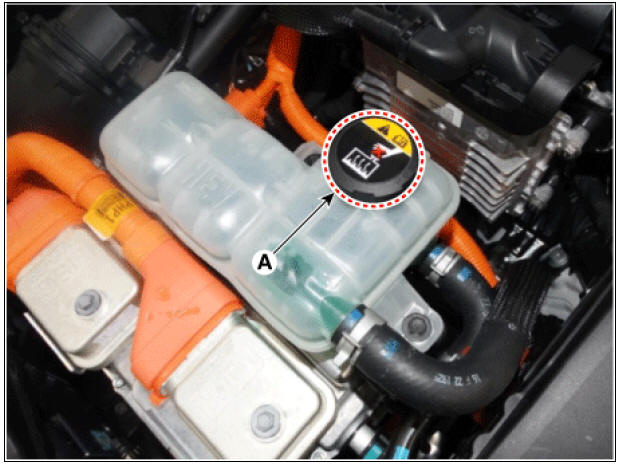

- Remove the inverter reservoir cap (A) to help drain the coolant faster.

- Remove the under cover.

- Remove the drain plug (A), allow the coolant to drain out and then reinstall the drain plug.

Tightening torque : 7.8 - 11.8 N*m (0.7 - 1. 4 kgf.m, 5.8 - 8.7 lb*ft)

- After draining coolant from the reservoir tank, clean the tank.

- Fill the radiator with water through the inverter reservoir cap and tighten the cap.

Warning

To most effectively bleed air, slowly pour water while pressing on the upper/lower radiator hoses.

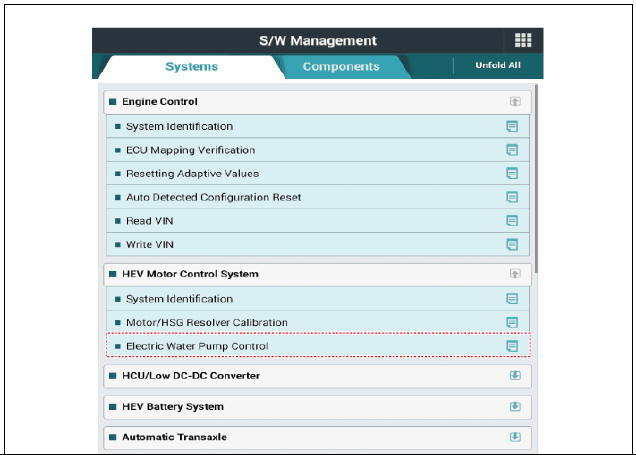

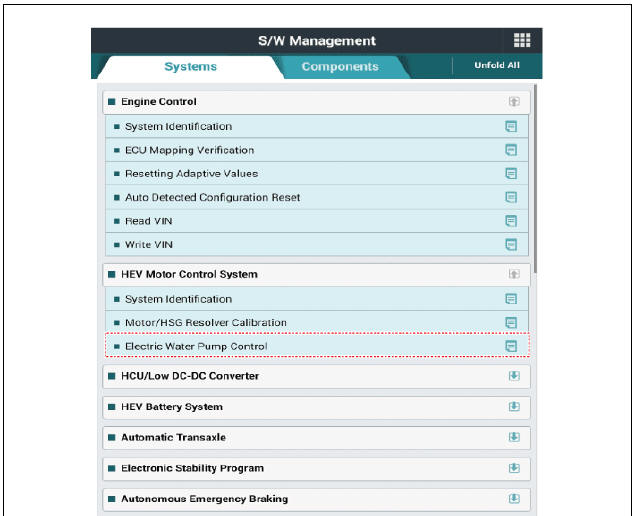

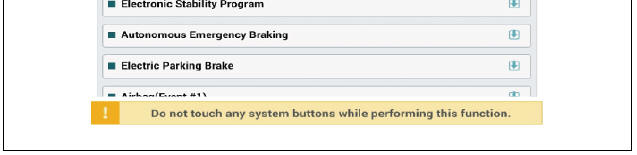

- Switch "ON" the ignition and then perform the EWP actuation using KDS.

- Repeat steps 1 to 6 until the drained water runs clear.

- Fill the reservoir with coolant. Slowly fill with the fluid mixture of coolant and water (45 - 50%).

Warning

- Use only genuine antifreeze / coolant.

- For best corrosion protection, the coolant concentration must be maintained year-round at 45% minimum. Coolant concentrations less than 55% may not provide sufficient protection against corrosion or freezing.

- Coolant concentrations greater then 60% will impair cooling efficiency and are not recommended.

- Perform the EWP actuation using KDS.

- While the EWP operates and coolant circulates, refill coolant so that the coolant level is kept between "MAX" and "MIN" levels.

Warning

If the EWP operates without a sufficient amount of coolant for approximately 5 seconds, the EWP protection function will be activated to stop the EWP for about 15 seconds. The EWP will start operating automatically when a sufficient amount of coolant is added.

- Air bleeding procedure of the coolant system is completed when the EWP operating sound gets lower and no more air bubbles are seen from the reservoir. (It would take about 3 - 5 minutes.)

Warning

After air bleeding, make sure that no air bubbles are present in the reservoir during the EWP actuation. If the coolant flow is not visible or air bubbles are still present, repeat steps 8 to 11.

- After air bleeding, stop the EWP, add coolant to the "MAX" level, and install the reservoir cap.

READ NEXT:

Driveshaft and axle

Driveshaft and axle

Service Data

Tightening Torques

Lubricants

Special Service Tools

Tool Name / Number/ Illustration/ Description

Ball joint puller

09568-34000/ / Remove the ball

joint

Puller

09495-33000/ /Used for removal of

spider assembly

Front Driveshaft Repair procedures

Front Driveshaft Repair procedures

Component location

Inner shaft bearing bracket

Drive shaft (RH)

Drive shasft (LH)

Front Driveshaft Repair procedures

Removal

Remove the wheel and tire.

Tightening torque:

107.9 - 127.5 N*m (11.0 - 13.0 kgf*m, 79.6 - 94.0 lb*ft

SEE MORE:

High Voltage Battery System / Components And Components Location / Repair Procedures

High Voltage Battery System / Components And Components Location / Repair Procedures

Description

The High Voltage Battery System provides the hybrid drive motor, HSG, and electric A/C compressor

with electric energy and also reserves the electric energy generated during regeneration braking.It

consists of the battery pack assemb

Engine Control System / Description And Operation

Engine Control System / Description And Operation

Description

If the Gasoline Engine Control system components (sensors, ECM, injector, etc.)

fail, interruption to the fuel supply or failure

to supply the proper amount of fuel for various engine operating conditions will

result. The following

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us