KIA Niro: Compressor oil Repair procedures | Refrigerant Line

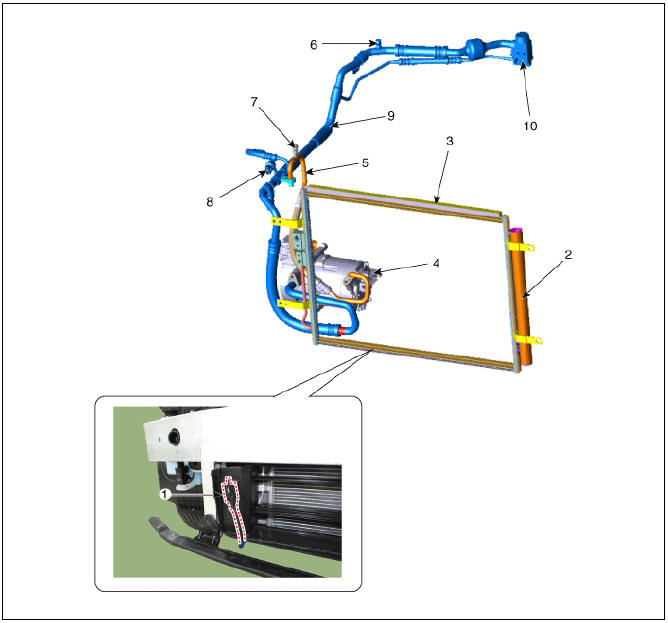

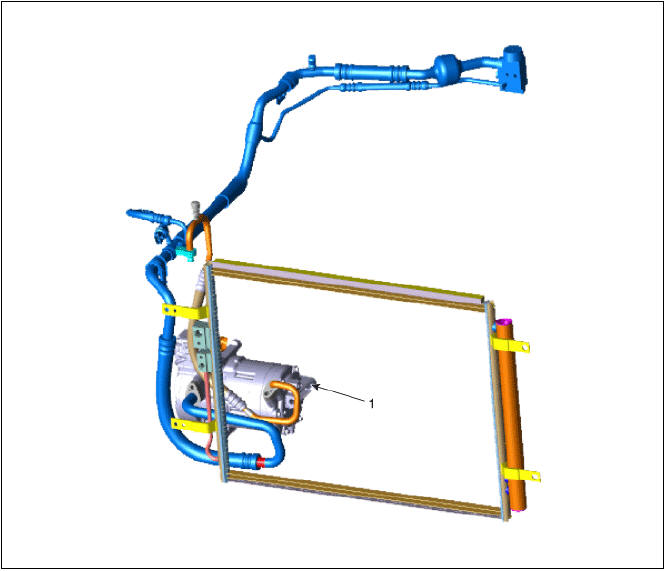

Air Conditioning System / Components And Components Location

Engine Room

- Ambient Temperature Sensor

- Receiver-drier

- Condenser

- Electric A/C Compressor

- Discharge hose

- The service port (Low pressure)

- The service port (High pressure)

- A/C Pressure Transducer (APT)

- Suction & Liquid tube assembly

- Expansion valve

Interior

- Auto Defogging sensor

- Photo sensor

- Heater & blower unit

- Evaporator Temperature Sensor

- Heater & A/C Control Unit

Compressor oil Repair procedures

Oil Specification

The oil used to lubricate the compressor circulates with the refrigerant.

Whenever replacing any component of the system or a large amount of gas leakage occurs, add oil to maintain the original amount of oil.

Total volume of oil in system POE OIL: 130 +- 10 g (4.58 +- 0.35 oz)

Oil Return Operation

There is close affinity between the oil and refrigerant.

During normal operation, part of the oil recirculates with the refrigerant in the system. When checking the amount of oil in the system, or replacing any component of the system, the compressor must run in advance for oil return operation. The procedure is as follows:

- Open all the doors and engine hood.

- Start the engine and air conditioning switch to "ON" and set the blower motor control knob at its highest position.

- Stop the engine.

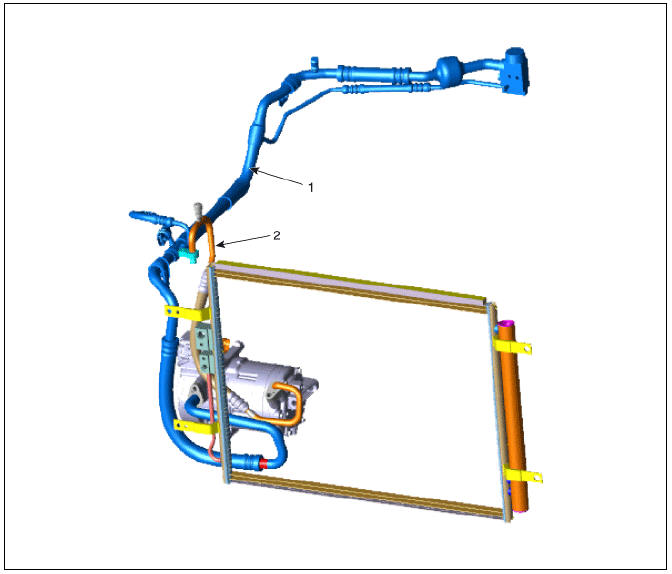

Refrigerant Line

- Suction & Liquid tube assembly

- Discharge hose

Replacement

- If a compressor is available, the air conditioner is operated for a few minutes in the engine idle state and then the engine is stopped.

- Disconnect the negative (-) battery terminal.

- Recover the refrigerant with a recovery/charging station.

- Remove the engine cover.

(Refer to Engine Mechanical System - "Engine Cover")

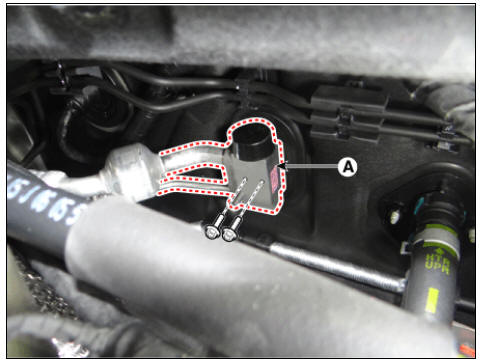

- Remove the bolts and the expansion valve (A) from the evaporator core.

Tightening torque : 7.8 - 11.8 N*m (0.8 - 1.2 kgf*m, 5.8 - 8.7 lb*ft)

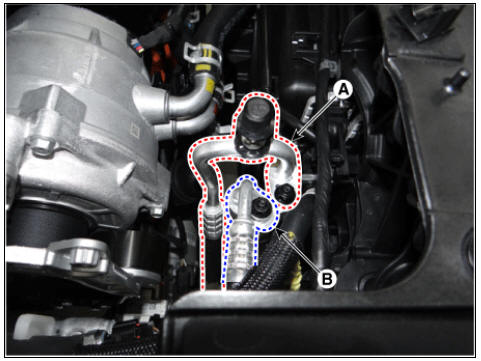

- Remove the 2 nuts, and then disconnect the discharge line (A) and liquid line (B) from the condenser.

Tightening torque : 7.8 - 11.8 N*m (0.8 - 1.2 kgf*m, 5.8 - 8.7 lb*ft)

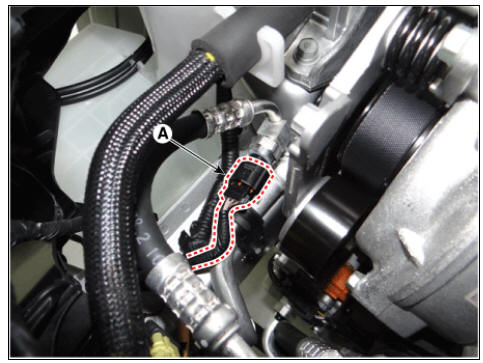

- Press the lock pin and separate the APT sensor connector (A).

- Remove the engine room under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

- Remove the engine mounting braket.

(Refer to Engine Mechanical System - "Engine Mounting")

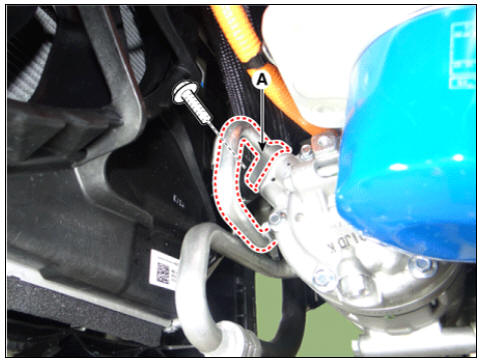

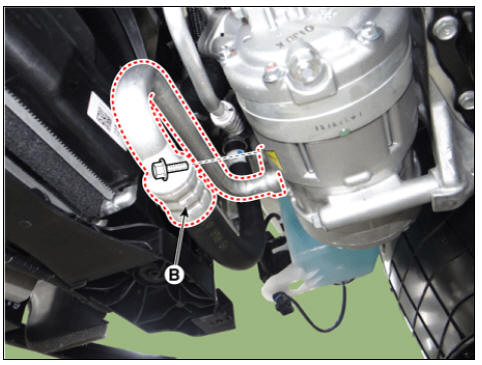

- Remove the nuts, then disconnect the suction line (A) and discharge line (B) from the compressor.

Tightening torque : 7.8 - 11.8 N*m (0.8 - 1.2 kgf*m, 5.8 - 8.7 lb*ft)

Warning

Plug or cap the lines immediately after disconnecting them to avoid moisture and dust contamination.

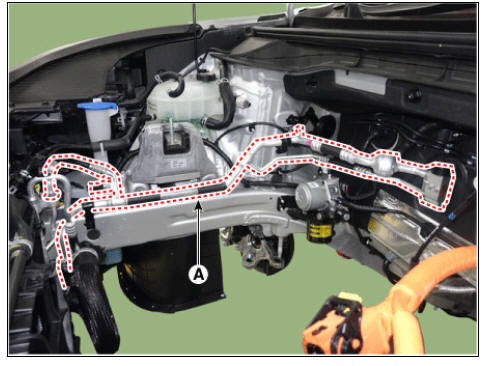

- Loosen the mounting bolts and remove the front suction & liquid pipe assembly (A).

Tightening torque : 7.8 - 11.8 N*m (0.8 - 1.2 kgf*m, 5.8 - 8.7 lb*ft)

Warning

- Plug or cap the lines immediately after disconnecting them to avoid moisture and dust contamination.

- Tighten the bolt or nut joint to the specified torque.

- Using a gas leak detector, check for refrigerant leakage.

- Evacuate air in the refrigeration system and charge system with refrigerant.

Specified amount R-134a, R-1234yf : 550 +- 25g (19.4 +- 0.88oz.)

Compressor Repair procedures

Compressor Components and components location

- Electric A/C Compressor

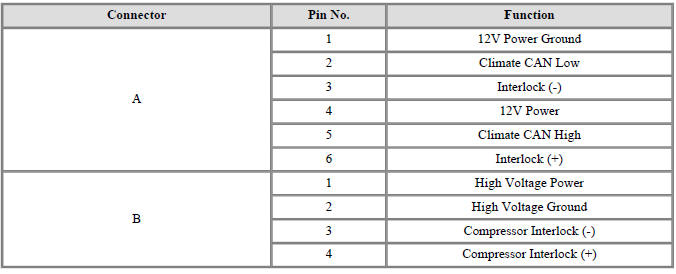

Compressor Schematic diagrams

Connector Pin

Connector Pin Function

READ NEXT:

Electric A/C Compressor

Electric A/C Compressor

Electric A/C Compressor body inside inspection

Electric compressor body inside check procedure.

1) Remove the low-pressure pipe from the electric compressor.

2) Check if the copper wire and white thread inside of the compressor was

contamin

Inverter kit / Body kit

Inverter kit / Body kit

Remove the battery (-) cable.

Disconnect the high voltage circuit. (Refer to Generals)

Use the recovery/reproduction/charging device to recover the coolant.

Warning

When removing the connector between the vehicle and the

compressor,

SEE MORE:

Parking on hills

Parking on hills

Generally, if you have a trailer attached

to your vehicle, you should not park your

vehicle on a hill. People can be seriously

or fatally injured, and both your vehicle

and the trailer can be damaged if unexpectedly

roll down hill.

However, i

Safety Plug Description and operation

Safety Plug Description and operation

Description

Safety Plug is installed on the rear side of the high voltage battery and it

can mechanically shut the

high voltage circuit off when servicing the high voltage system. (i.e. High

Voltage Battery, Power

Relay Assembly, HPCU, BMS ECU

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us