KIA Niro: TJ Joint Repair procedures

Removal

Warning

- Drive shaft joints require special grease, so do not add any other type of grease.

- When replacing the boot band, it must be a new one.

- Remove the front drive shaft.

(Refer to Driveshaft Assembly - "Front Driveshaft")

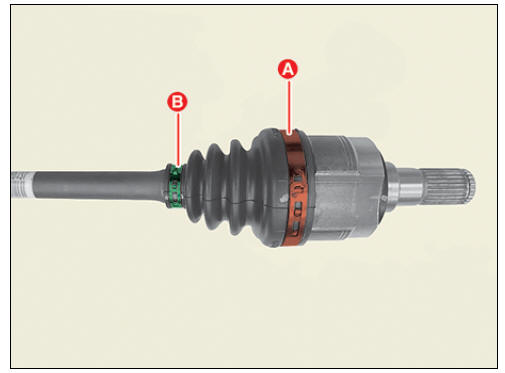

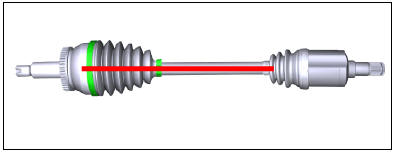

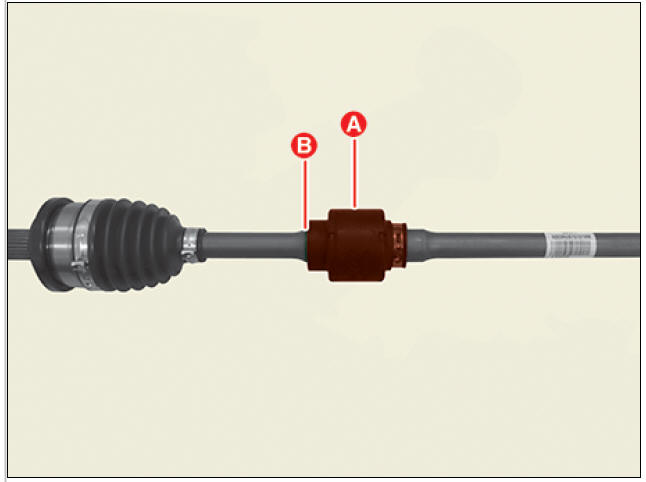

- Remove the transaxle side large diameter (A) and small diameter (B) boot bands.

Warning

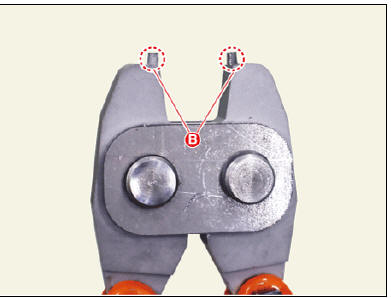

Use the right tool for each type of boot band as shown in the table

below.

Warning

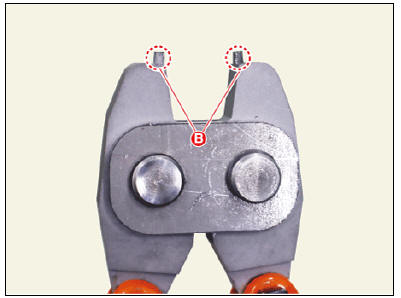

When using the low profile hook type boot band, fit the SST tip (B)

into the boot band hole (A) as shown below.

- Remove the trans axle joint housing (A).

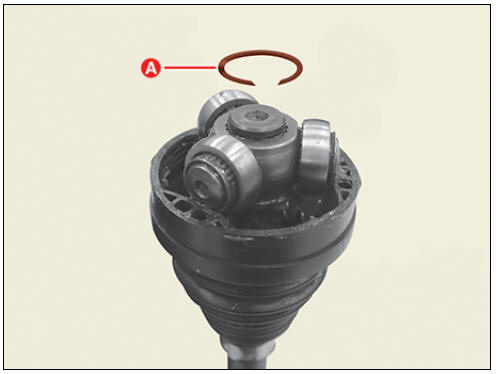

- Remove the snap ring (A) using a snap ring pliers.

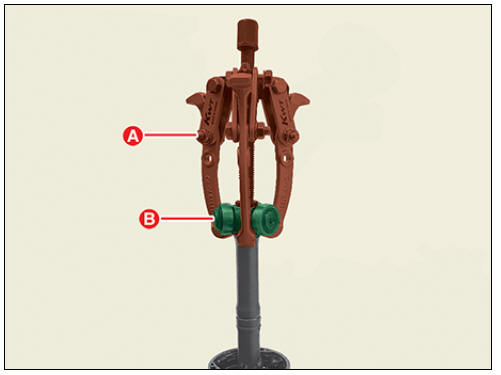

- Remove the spider assembly (B) from the drive shaft using a puller (A).

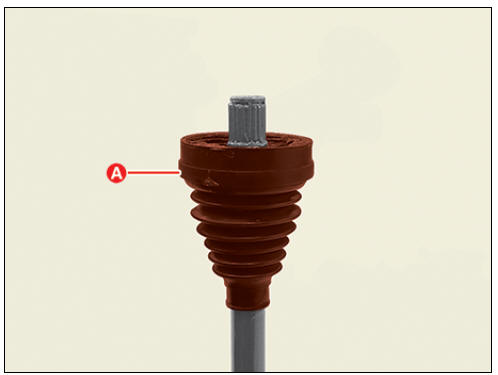

- Remove trans axle side boot (A).

- Clean the inside of the spider assembly and joint housing.

Warning

Remove grease inside the housing as much as possible.

Inspection

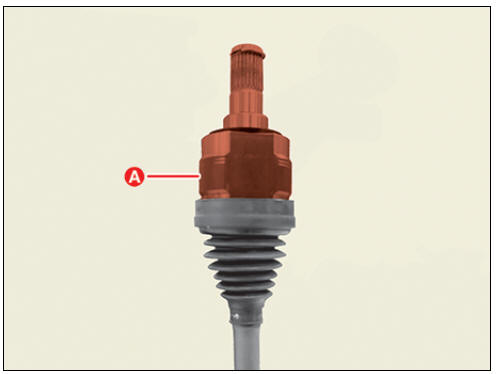

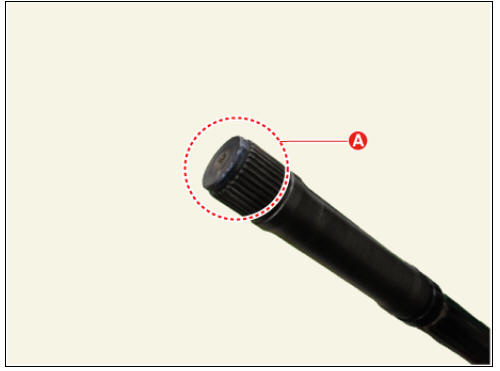

- Check spline (A) for damage / wear / crack.

- Check the boot for water or foreign objects.

- Check joint assembly for damage / wear / crack and rust.

- Replace any defective parts.

Installation

Warning

- When assembling, be careful not to let dust and foreign substances enter.

- Driveshaft joints require special grease, so do not add any other type of grease.

- Boot bands must use the new one.

- Install the transaxle side boot (A) and boot band (B) on the driveshaft.

Warning

Put the boot band (B) first on the drive shaft before installing the boot (A).

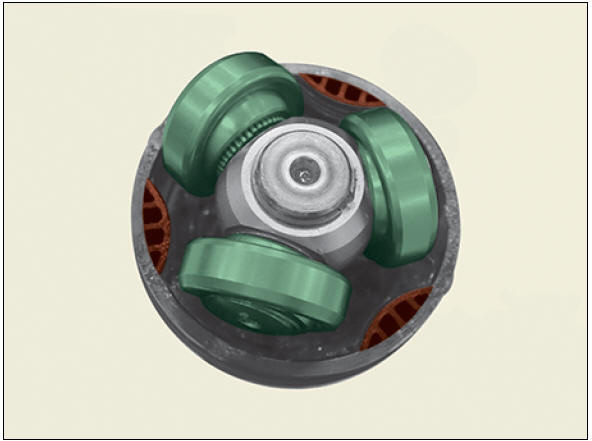

- Install the spider assembly (A) on the shaft (B), then press it using a mallet.

Warning

When installing

the spider assembly (A), install it in the correct direction.

When installing

the spider assembly (A), install it in the correct direction.- Installing in the wrong direction can cause secondary quality problems.

- Install the snap ring (A) using the snap ring pliers.

Warning

- When replacing the joint assembly, use the new one provided in the joint kit.

- The snap ring must be new.

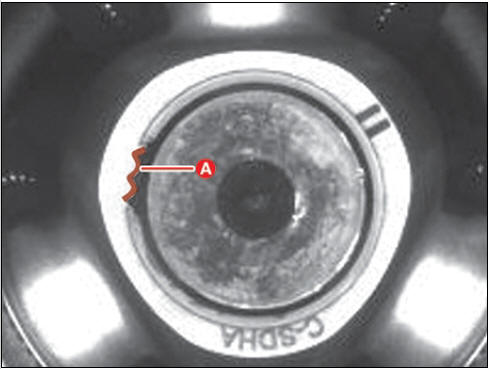

- After installing the snap ring, make sure that there are only 2

- 3 splines in position (A).

- Install the transaxle side joint boot (A) in the correct position.

Warning

- When installing boot (A), make sure the boot fits into the

groove (B).

- When installing the spider assembly, fit the assembly to the

boot shape.

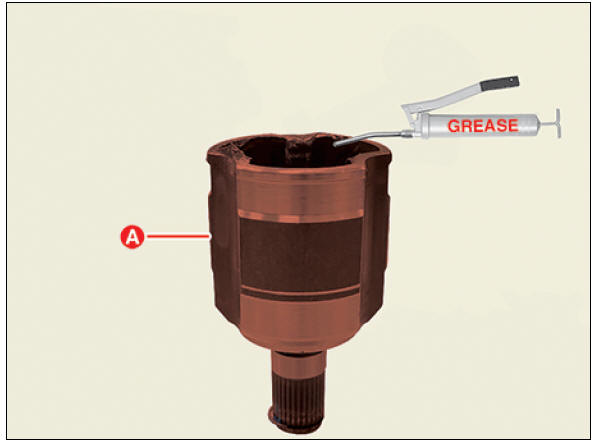

- Apply specified grease inside the joint housing (A) and boot (B).

Warning

- Use the grease provided with the joint/boot kit.

- Apply about 70% grease to the housing (A) and about 30% grease to the boot (B).

- Driveshaft joints require special grease, so do not add any other type of grease.

- Install the trans axle side joint housing (A).

Warning

- When installing the housing, turn the boot to fit each other.

- If the shape of housing and boot does not fit, there is a possibility of leakage due to the gap. Be very careful.

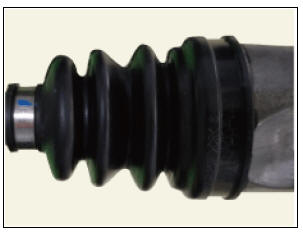

- Adjust the air inside the boot to normal as shown below.

Normal

Normal

Lack of air

Lack of air

Too much air

Too much air

- Install the transaxle side joint large diameter (A) and small diameter (B) boot band.

Warning

Use the right tool for each type of boot band as shown in the table

below.

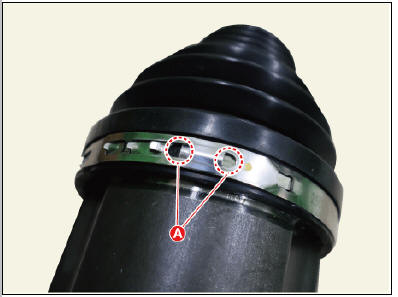

Warning

- Install in the following order: large diameter boot band (A) Õ small diameter boot band (B).

- Installing in the wrong order can cause leaks.

- When installing the boot band, align the fastened direction

with the wheel side joint boot band.

- When installing the ear type boot band, check the clearance (A) as shown below.

Clearance (A) : 2.0 mm or less.

- When using the low profile hook type boot band, fit the SST tip

(B) into the boot band hole (A) as shown below.

- Install the front drive shaft.

(Refer to Driveshaft Assembly - "Front Driveshaft")

TJ Joint Repair procedures

Removal

- Remove the front drive shaft.

(Refer to Driveshaft Assembly - "Front Driveshaft")

- Remove the trans axle side joint.

(Refer to Driveshaft Assembly - "Joint Assembly (Transaxle side)")

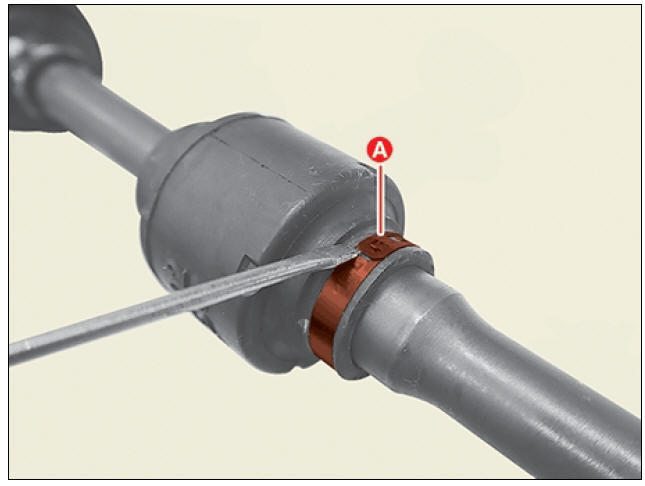

- Remove the dynamic damper band (A) using driver (-).

Warning

When removing the dynamic damper, lubricate the shaft with soapy

water to prevent shaft

damage.

- Remove the dynamic damper (A).

Installation

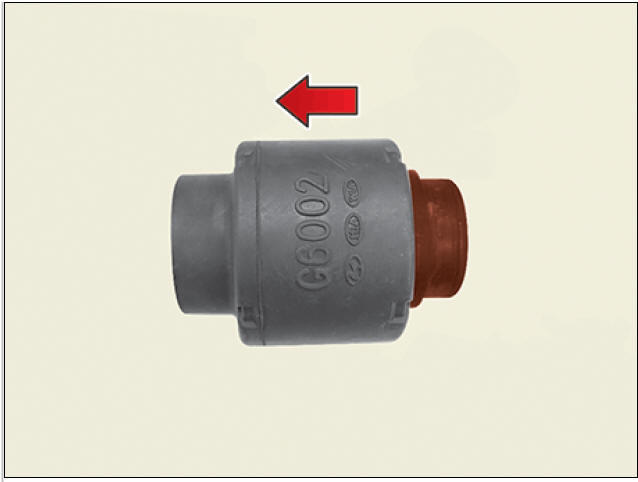

- Install the dynamic damper (A).

Warning

When installing the dynamic damper, install it in the direction of

the arrow. Installing in the

wrong direction can cause secondary quality problems.

- Install the dynamic damper band (A) using SST (09495-39100).

Warning

When installing the dynamic damper (A), make sure that the damper

fits into the groove (B).

- Install the transaxle side joint.

(Refer to Driveshaft Assembly - "Joint Assembly(Transaxle side)")

- Install the front driveshaft.

(Refer to Driveshaft Assembly - "Front Driveshaft")

READ NEXT:

Driveshaft Assembly

Driveshaft Assembly

Removal

The type can replace the wheel side joint boot

Remove the front driveshaft.

(Refer to Driveshaft Assembly - "Front driveshaft")

Remove the transaxle side joint.

(Refer to Driveshaft Assembly - "Joint Assembly(Tra

Front Hub / Knuckle

Front Hub / Knuckle

Components

Brake disc

Hub assembly

Dust cover

Knuckle

Front Hub / Knuckle / Repair Procedures

Removal

Remove the wheel and tire.

Tightening torque :

107.9 - 127.5 N*m (11.0 - 13.0 kgf*m, 79.6 - 94.0 lb*ft)

Warning

Be c

Rear Axle Assembly / Rear Hub - Carrier

Rear Axle Assembly / Rear Hub - Carrier

Components

Disc

Dust cover

Rear hub

Rear Knuckle

Rear Hub - Carrier / Repair Procedures

Removal

Remove the tire (A).

Tightening torque :

107.9 - 127.5 N*m (11.0 - 13.0 kgf*m, 79.6 - 94.0 lb*ft)

Warning

Be careful not t

SEE MORE:

Emergency Stop Signal (ESS)

Emergency Stop Signal (ESS)

The Emergency Stop Signal (ESS) alerts

the driver behind by flashing the brake

lights when braking sharply and

severely.

Operating condition(s)

The vehicle suddenly stops.

ABS is activated and the driving speed

is over 55 km/h (34 mph).

Door locks inside the vehicle

Door locks inside the vehicle

Unlocking with the door handle

Operation

Front door

If the inner door handle is pulled once

when the door is locked, the door will

unlock and open.

Rear door

If the inner door handle is pulled once

when the door is locked, the d

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us