KIA Niro: Steering Angle Sensor (SAS) Calibration | Part replacement (Power steering ECU)

Warning

- Check that the battery is fully charged before "Steering Angle Sensor (SAS) Calibration".

- Be careful not to disconnect any cables connected to the vehicle or scan tool during "Steering Angle Sensor (SAS) Calibration".

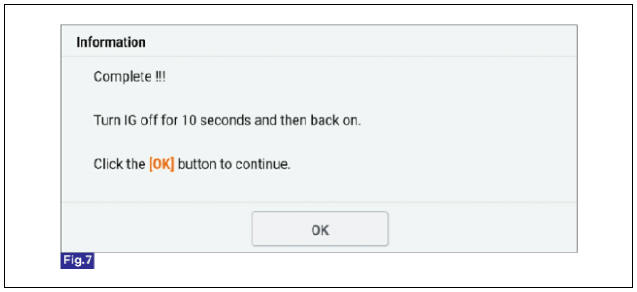

- After completing the "Steering Angle Sensor (SAS) Calibration", switch off the ignition and wait for several seconds. Then, start the engine to confirm normal operation of the vehicle.

- Connect self-diagnosis connector (16pins) located under the driver side crash pad to self-diagnosis device, and then turn the selfdiagnosis device after key is ON.

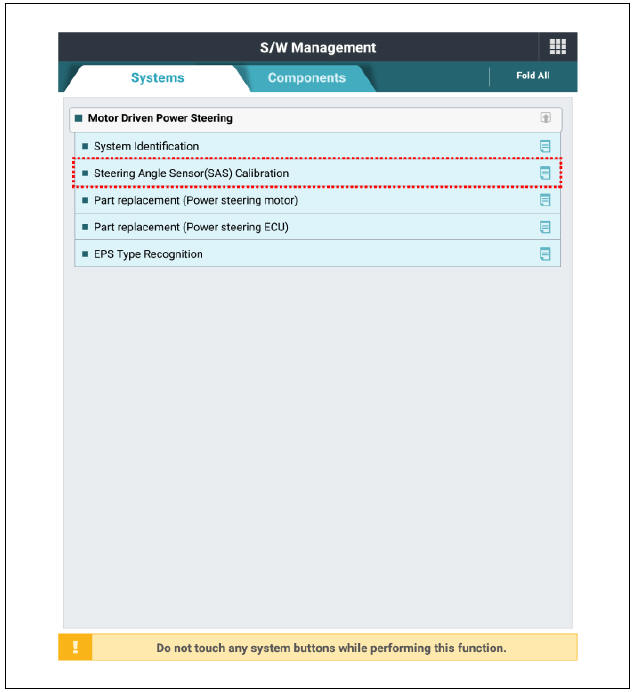

- Select the "vehicle model" and "Motor Driven Power Steering" on KDS vehicle selection screen.

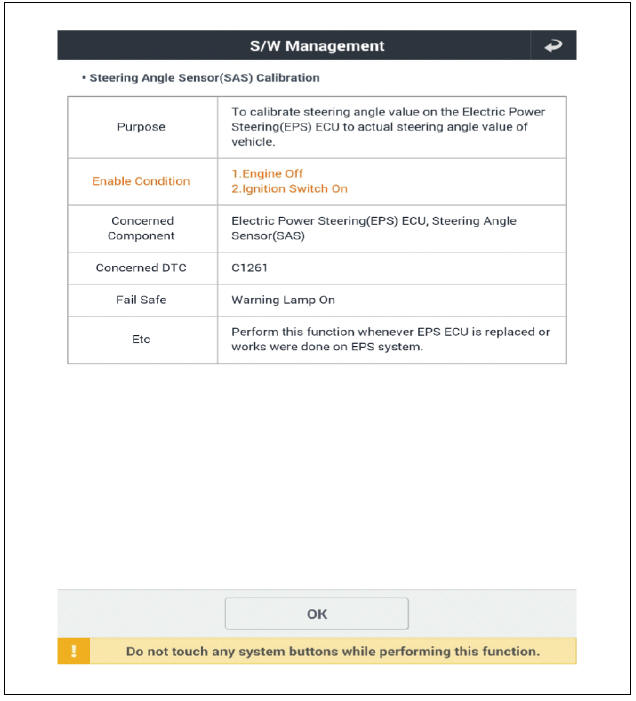

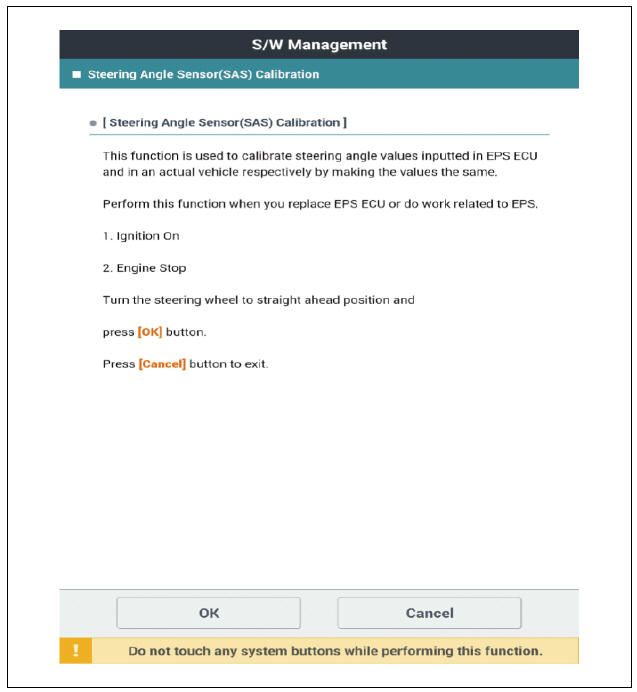

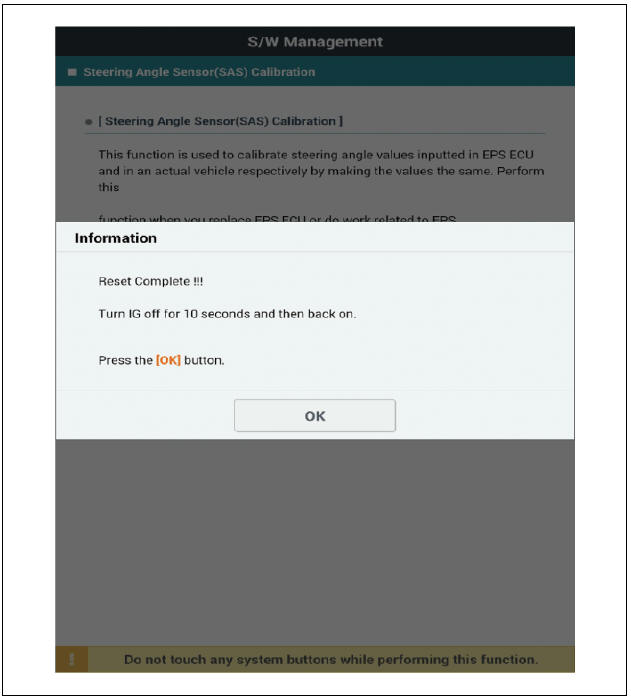

- Select the "Steering Angle Sensor (SAS) Calibration" on KDS screen, then select OK.

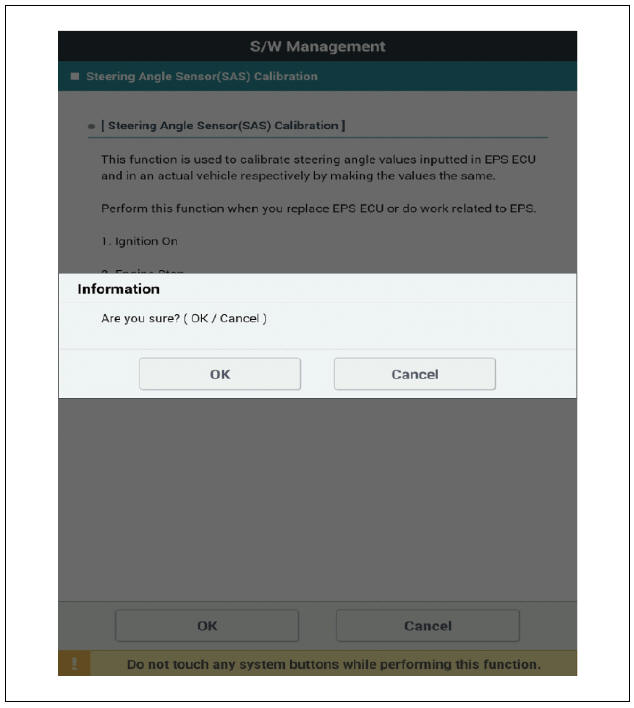

- Proceed with the test according to the screen instructions.

- Remove the DTC.

- Turn off the IG switch and wait for 10 seconds or more before starting the engine. And then make sure that MDPS works properly.

Part replacement (Power steering ECU)

Replacement

Warning

- If a DTC occurs in the ECU, check the connectors and wiring. If no problem is found, replace the ECU.

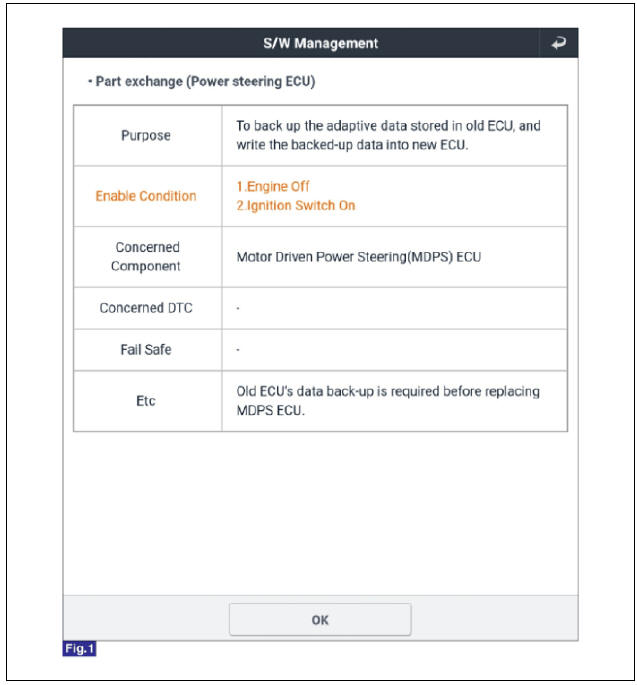

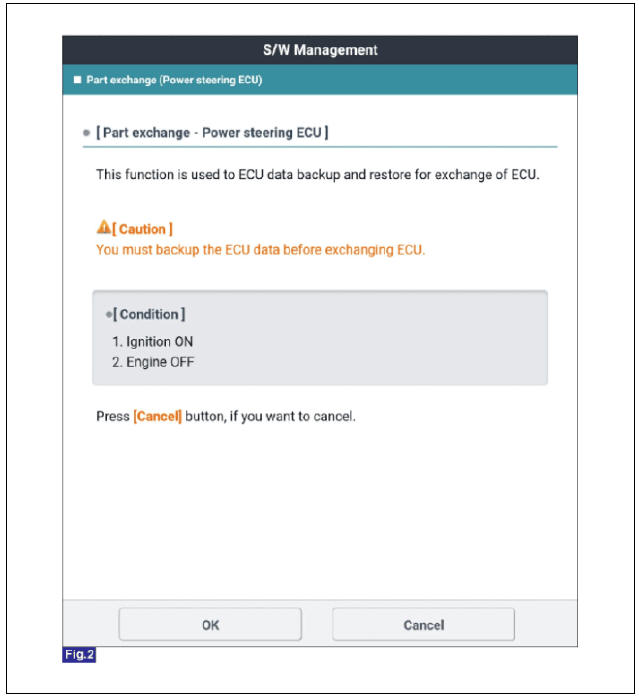

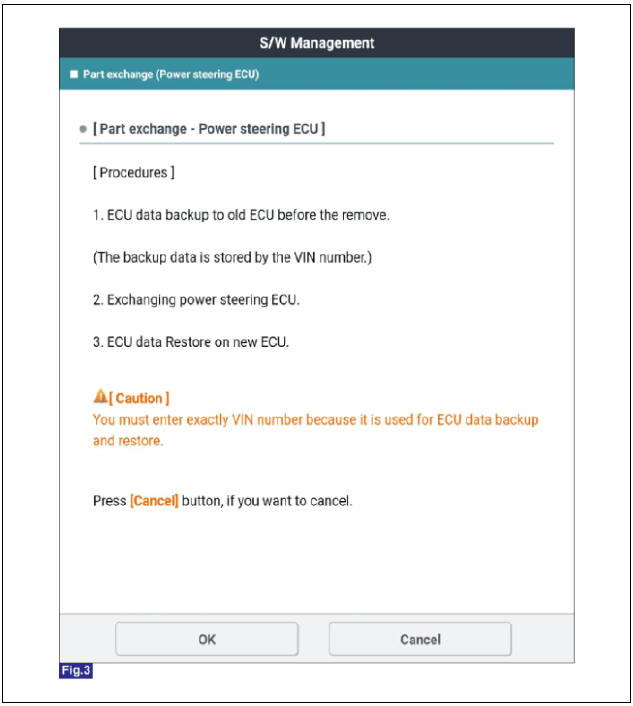

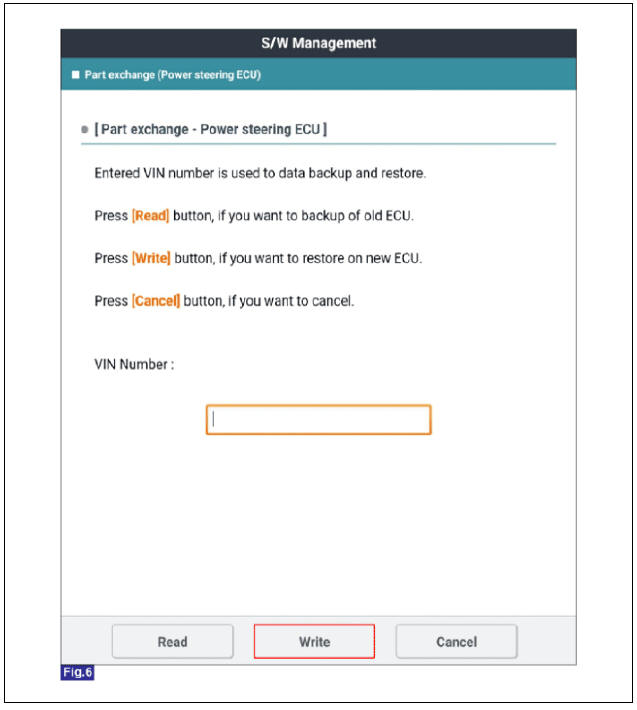

- Before replacing the MDPS ECU, use the diagnostic device to read the settings of the old ECU

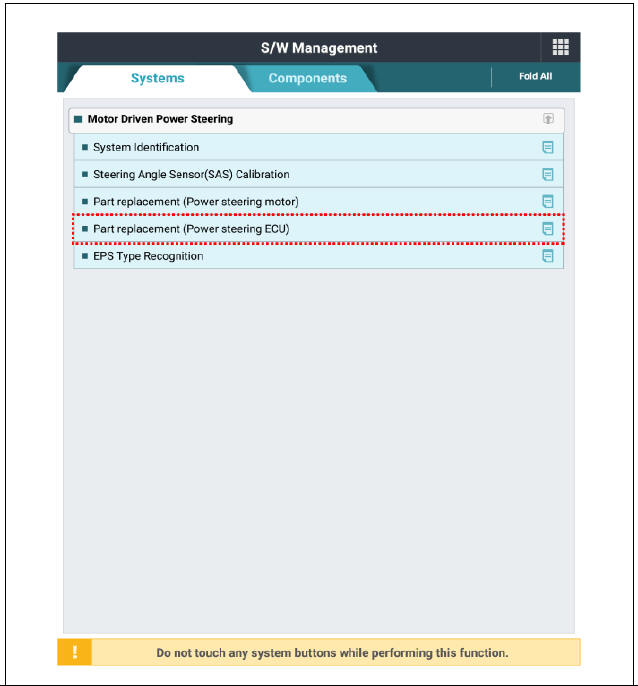

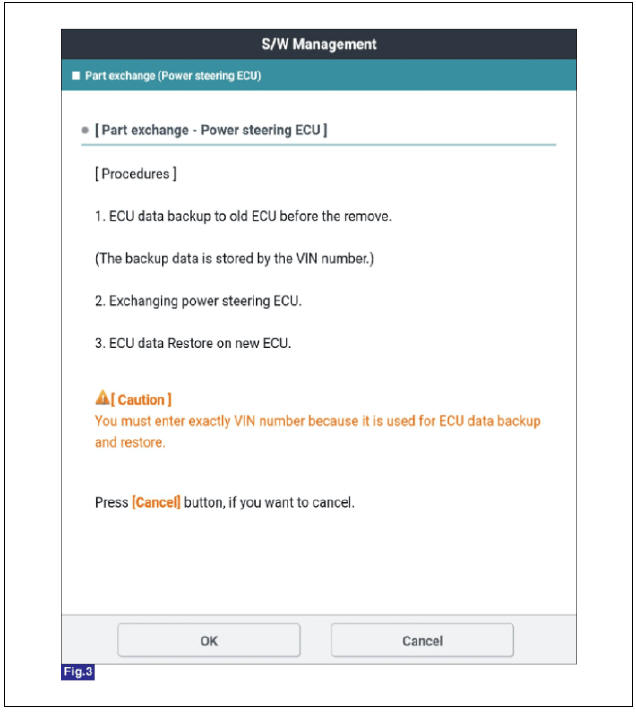

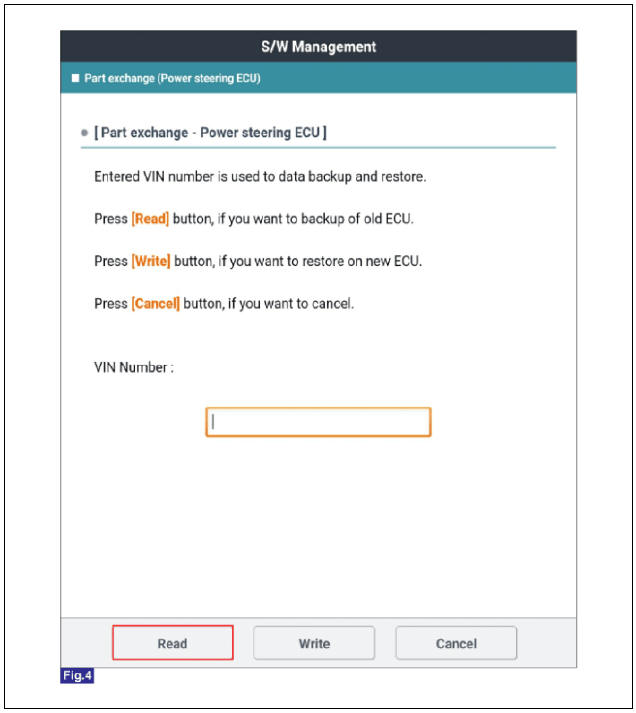

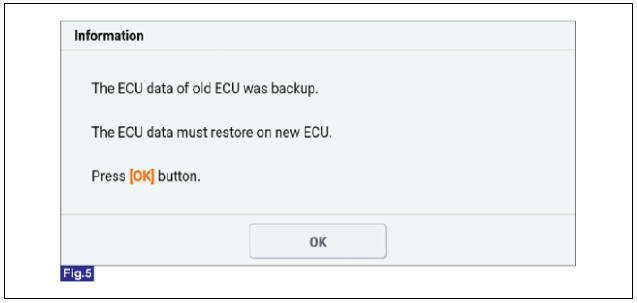

- Perform the "Motor Driven Power Steering" by KDS following in the order below.

(1) Connect self-diagnosis connector (16pins) located under the driver side crash pad to self-diagnosis device, and then turn the self-diagnosis device after key is ON.

(2) Select the "vehicle model" and "Motor Driven Power Steering" on KDS vehicle selection screen.

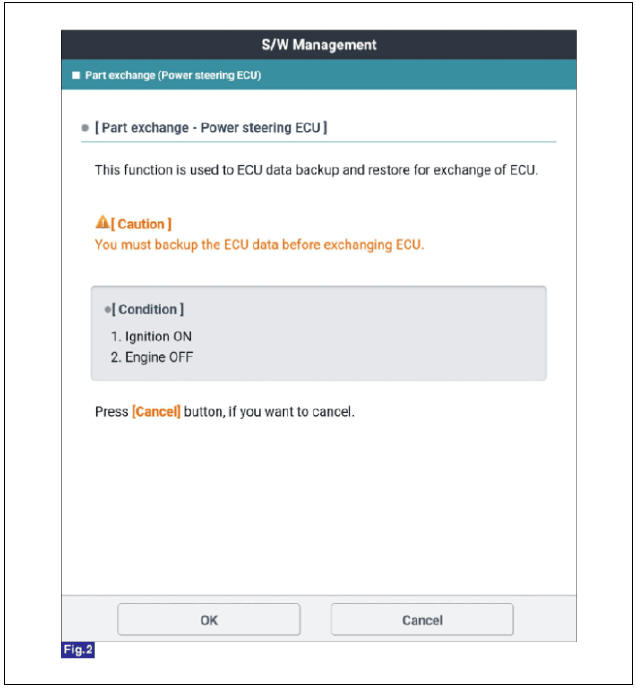

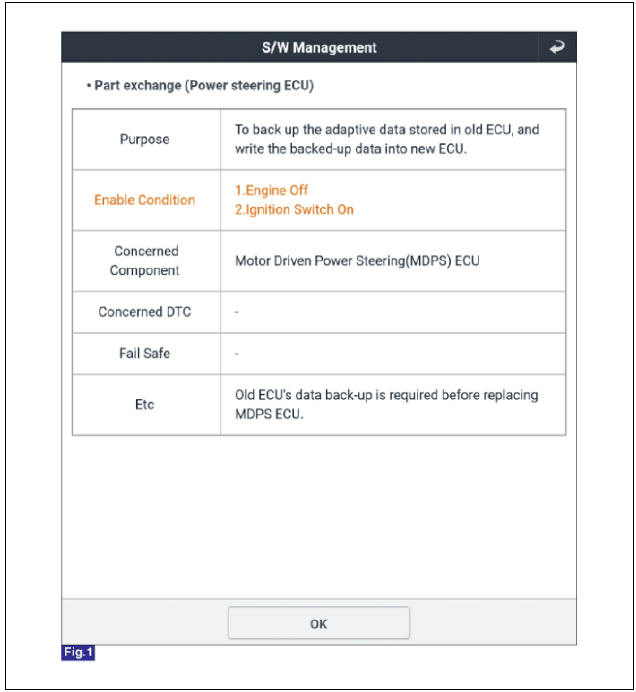

(3) Select the "Part replacement (Power steering ECU)" on KDS screen, then select OK.

(4) Proceed with the test according to the screen instructions.

Warning

If a DTC occurs in the ECU, check the connectors and wiring. If no problem is found, replace the ECU.

- Disconnect the battery negative terminal.

- Remove the crash pad lower panel.

(Refer to Body - "Crash pad lower panel")

- Remove the knee airbag (KAB) module.

(Refer to Restraint - "Knee Airbag (KAB) Module")

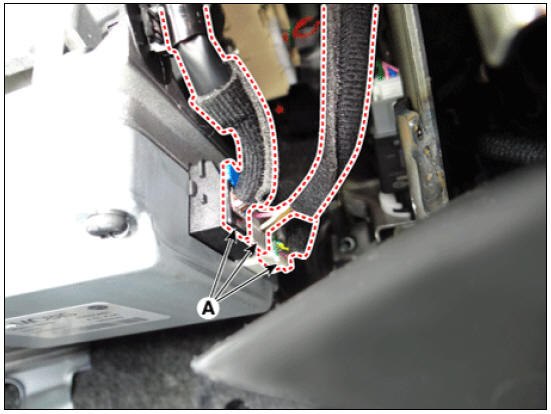

- Disconnect the MDPS ECU connectors (A).

- Loosen the mounting bolts (A) and then remove the MDPS ECU (B).

Tightening torque : 19.6 - 23.5 N*m (2.0 - 2.4 kgf*m, 14.5 - 17.4 lb*ft)

- Install in the reverse order of removal.

- Perform the "Motor Driven Power Steering" by KDS following in the order below.

(1) Connect self-diagnosis connector (16pins) located under the driver side crash pad to self-diagnosis device, and then turn the self-diagnosis device after key is ON.

(2) Select the "vehicle model" and "Motor Driven Power Steering" on KDS vehicle selection screen.

(3) Select the "Part replacement (Power steering ECU)" on KDS screen, then select OK.

(4) Proceed with the test according to the screen instructions.

- Perform the "Steering Angle Sensor (SAS) Calibration" and "Set the steering feel torque to zero".

- Turn off the IGN switch and wait for 10 seconds or more. Then check the operation after starting the engine.

READ NEXT:

Steering Angle Sensor (SAS) Calibration and Set the steering feel torque to

zero

Steering Angle Sensor (SAS) Calibration and Set the steering feel torque to

zero

Diagnosis with KDS

Warning

Check that the battery is fully charged before "Steering Angle

Sensor (SAS) Calibration".

Be careful not to disconnect any cables connected to the

vehicle or scan tool during "Steering Angle Sens

MDPS Tuning Data Setting | Steering Column and Shaft Repair procedures

MDPS Tuning Data Setting | Steering Column and Shaft Repair procedures

Since MDPS can store various tuning maps with different steering feelings in the ECU and different steering feelings depending on the application area and the vehicle engine type, it is necessary to set codes appropriate for the applicatio

SEE MORE:

Engine Oil Level

Engine Oil Level

Warning

Be sure that the vehicle is on level ground.

Warm up and stop the engine, and then wait for 5 minutes.

Turn the engine off and wait for a few minutes (about 5 minutes) for the

oil to return to the oil pan.

Pull the dipstick out, w

Identification Number Locations

Identification Number Locations

Identification Numbers

Identification Number Description

Vehicle Identification Number

World Manufacturer Identifier (WMI)

KNA : Passenger vehicle, MPV(Multipurpose Passenger Vehicle)/SUV(Sports

Utility Vehicle)/RV(Recreational

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us