KIA Niro: Refrigerant System Service Basics (R- 134a)

- For the electric compressor using high-voltage, use POE oil with high insulation property.

- Use a separate equipment (refrigerant recovery / charger) exclusive for hybrid vehicle maintenance to prevent infusion of PAG oil of non-hybrid vehicles during refrigerant recovery / charging.

Warning

If PAG oil mixes into the POE oil of the system, dielectric breakdown may occur due to decreased volumetric resistivity and the A/C compressor may not work.

Refrigerant Recovery

Use only the UL-listed service equipment certified to meet the requirements of SAE J2210 to remove HFC-134a (R-134a) from the air conditioning system.

Warning

- Air conditioning refrigerant or lubricant vapor can irritate your eyes, nose, or throat.

- Be careful when connecting service equipment.

- Do not breathe in refrigerant or vapor

If accidental system discharge occurs, ventilate the work area before resume of service.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers.

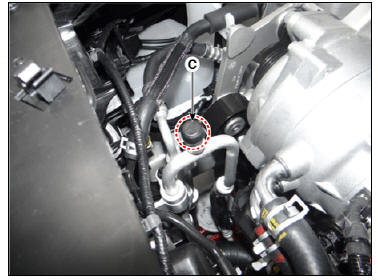

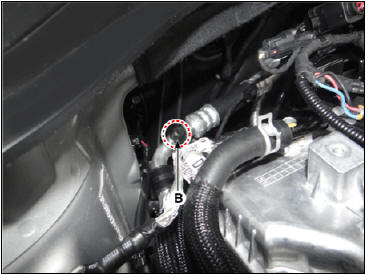

- Connect an R-134a refrigerant Recovery / Recycling / Charging system (A) to the high-pressure service port (C) and the low-pressure service port (B) as shown, following the equipment manufacturer's instructions.

- Measure the amount of refrigerant oil removed from the A/C system after the recovery process is completed. Be sure to install the same amount of new refrigerant oil back into the A/C system before charging.

System Evacuation

Use only the UL-listed service equipment certified to meet the requirements of SAE J2210 to remove HFC-134a (R-134a) from the air conditioning system.

Warning

- Air conditioning refrigerant or lubricant vapor can irritate your eyes, nose, or throat.

- Be careful when connecting service equipment.

- Do not breathe in refrigerant or vapor.

If accidental system discharge occurs, ventilate the work area before resume of service.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers.

- When an A/C system has been open to the atmosphere, during installation or service, it must be evacuated using an R-134a refrigerant Recovery / Recycling / Charging system. (If the system has been open for several days, the receiver / drier should be replaced, and the system should be evacuated for several hours.)

- Connect an R-134a refrigerant Recovery / Recycling / Charging system (A) to the high-pressure service port (C) and the low-pressure service port (B) as shown, following the equipment manufacturer's instructions.

- If the low-pressure does not reach more than 93.3 kPa (700 mmHg, 27.6 in.Hg) in 10 minutes, there is probably a leak in the system. Partially charge the system, and check for leaks (see Refrigerant Leak Test.)

- Remove the low pressure valve from the low-pressure service port.

System Charging

Use only the UL-listed service equipment certified to meet the requirements of SAE J2210 to remove HFC-134a (R-134a) from the air conditioning system.

Warning

- Air conditioning refrigerant or lubricant vapor can irritate your eyes, nose, or throat.

- Be careful when connecting service equipment.

- Do not breathe in refrigerant or vapor.

If accidental system discharge occurs, ventilate the work area before resume of service.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers.

- Connect an R-134a refrigerant Recovery / Recycling / Charging system (A) to the high-pressure service port (C) as shown, following the equipment manufacturer's instructions.

- Add the same amount of new refrigerant oil to the system that was removed during recovery. Use only specified refrigerant oil. Charge the system with R-134a refrigerant. Do not overcharge the system as this will damage the compressor.

Capacity : 550 +- 25g (19.4 +- 0.88 oz.)

Refrigerant Leak Test

Always conduct a leak test with an electronic leak detector whenever leakage

or refrigerant is suspected and when conducting service operations accompanied

by disassembly or

loosening or connection fittings.

Warning

For proper use of the leak detector, follow the manufacturer instructions.

If a gas leak is detected, proceed as follows:

- Check the torque on the connection fittings. If it is too loose, tighten to the proper torque. Check for gas leakage with a leak detector (A).

- If leakage continues even after the fitting has been tightened, discharge the refrigerant from the system, disconnect the fittings, and check their seating faces for damage. Always replace, even if the damage is slight.

- Check the compressor oil and add oil if required.

- Charge the system and recheck for gas leaks. If no leaks are found,

evacuate and charge the system again.

READ NEXT:

Refrigerant System Service Basics (R- 1234yf)

Refrigerant System Service Basics (R- 1234yf)

Refrigerant Identification

Do not mix HFO-1234yf (R-1234yf) in the vehicle with other refrigerant,

such as R-12, R-134a and etc.

Use only the UL-listed service equipment certified to meet the

requirements of SAE standards to recover and r

Filter inspection

Filter inspection

The climate control air filter should be replaced according to the

maintenance schedule.

If the vehicle is operated in severely air-polluted cities or on dusty rough

roads for a long period, it

should be inspected more frequently and replaced

Normal Maintenance Schedule - For Gasoline Engine

Normal Maintenance Schedule - For Gasoline Engine

The following maintenance services must be performed to ensure good emission

control and

performance. Keep receipts for all vehicle emission services to protect your

warranty.Where both

mileage and time are shown, the frequency of service is de

SEE MORE:

Tailgate Assembly

Tailgate Assembly

Tailgate / Repair Procedures

Adjustment

After loosening the tailgate hinge (A) mounting

bolts, adjust the tailgate by moving it up and down, or right and left.

Adjust the tailgate height by turning the tailgate

overslam bumpers (B).

Af

When the telltale lights up

When the telltale lights up

Low tire pressure telltale

Low tire pressure position telltale

A: Low tire pressure

Condition(s)

One or more of the tires is significantly

under-inflated.

Operation

The corresponding position light will

light up to indicate whi

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us