KIA Niro: Rail Pressure Sensor (RPS)

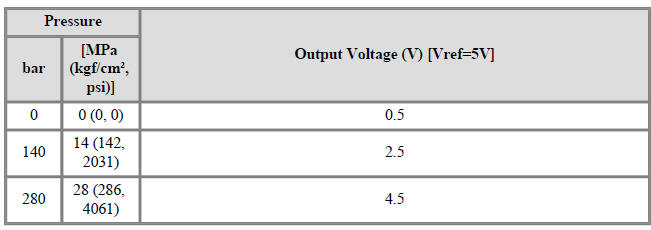

Specification

Rail Pressure Sensor (RPS) Description and operation

Description

Installed on the delivery pipe, the Rail Pressure Sensor (RPS) measures the

instantaneous fuel pressure

in the delivery pipe. The sensing element (Semiconductor element) built in the

sensor converts the

pressure to voltage signal. By using this signal, the ECM can control correct

injection amount and

timing and adjusts the fuel pressure with the fuel pressure regulator valve if

the target pressure is

different from the actual pressure calculated by the RPS output signal.

Circuit Diagram

Harness Connector

Rail Pressure Sensor (RPS) Repair procedures

Inspection

- Connect the KDS on the Data Link Connector (DLC).

- Measure the output voltage of the RPS during idle at various engine speeds.

Removal

- Release the residual pressure in fuel line.

(Refer to Fuel Delivery System - "Release Residual Pressure in Fuel Line").

- Switch "OFF" the ignition and disconnect the negative (-) battery terminal.

- Remove the intake manifold.

(Refer to Engine Mechanical System - "Intake Manifold")

- Remove the injector foam (A).

- Disconnect the rail pressure sensor connector (A), and then remove the sensor (B) from the delivery pipe.

Rail Pressure Sensor : 30.0 - 34.3 N*m (3.0 - 3.5 kgf*m, 22.1 - 25.3 lb*ft)

Installation

Warning

- Install the component to the specified torque.

- Note that internal damage may occur when the component is dropped. If the component has been dropped, inspect before installing.

- Install in the reverse order of removal.

Signal Waveform

БЮ

Fig.2) Nomal signal waveform of rail pressure sensor at engine idle.

БЮ

Fig.2) Nomal signal waveform of rail pressure sensor at engine idle.

READ NEXT:

Accelerator Position Sensor (APS)

Accelerator Position Sensor (APS)

Specification

Accelerator Position Sensor (APS) Description and operation

Description

Installed on the accelerator pedal module, the Accelerator Position Sensor (APS)

detects the rotation

angle of the accelerator pedal. The APS is one o

Injector

Injector

Specification

Description

The GDI injector is similar to a standard injector, but sprays fuel at a much

higher pressure directly

into the combustion chamber and has a swirl disc to get the fuel swirling as it

exits the nozzle. This

aids i

Purge Control Solenoid Valve (PCSV)

Purge Control Solenoid Valve (PCSV)

Specification

Purge Control Solenoid Valve (PCSV) Description and operation

Description

Installed on the intake manifold, the Purge Control Solenoid Valve (PCSV)

controls the evaporative

purge between the canister and the intake manifold. I

SEE MORE:

Button Engine Start System / Description And Operation

Button Engine Start System / Description And Operation

Button Engine Start System / Components And Components Location

Body control module (BCM)

Smart key unit (SMK)

Interior antenna 1

Interior antenna 2

FOB key

Start Stop Button (SSB)

Door handle & door antenna

Bumper ant

Engine Oil Repair procedures

Engine Oil Repair procedures

Warning

Prolonged and repeated contact with mineral oil will result in

the removal of natural fats from the skin, leading to

dryness, irritation and dermatitis. In addition, used engine oil contains

potentially harmful contaminants which

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us