KIA Niro: Positive Crankcase Ventilation (PCV) Valve Repair procedures | Canister Repair procedures

Removal

- Disconnect the vapor hose (A).

- Remove the PCV valve (B).

Inspection

- Insert a thin stick (A) into the PCV valve (B) from the threaded side to check the plunger movement.

Warning

If the plunger does not move (PCV valve is clogged), clean or replace the valve.

Installation

- Install in the reverse order of removal.

PCV valve :

1.96 - 2.94 N*m (0.2 - 0.3 kgf*m, 1.45 - 2.17 lb*ft)

Schematic Diagram

- Air cleaner

- Delivery pipe & injector

- Engine

- Purge control solenoid valve (PCSV)

- Fuel tank air filter

- High pressure fuel pump

- Fuel filler hose

- Fuel filler cap

- Fuel tank

- Low pressure fuel pump

Canister

Canister is filled with charcoal and absorbs evaporated vapor in fuel tank. The gathered fuel vapor in canister is drawn into the intake manifold by the ECM/PCM when appropriate conditions are set.

Purge Control Solenoid Valve (PCSV)

Purge Control Solenoid Valve (PCSV) is installed in the passage connecting canister and intake manifold. It is a duty type solenoid valve and is operated by ECM/PCM signal.

To draw the absorbed vapor into the intake manifold, the ECM/PCM will open the PCSV, otherwise the passage remains closed.

Fuel Filler Cap

A ratchet tightening device on the threaded fuel filler cap reduces the chances of incorrect installation, which would seal the fuel filler. After the gasket on the fuel filler cap and the fill neck flange contact each other, the ratchet produces a loud clicking noise indicating the seal has been set.

Canister Repair procedures

Description

Evaporative Emission Control System prevents fuel vapor stored in fuel tank from vaporizing into the atmosphere. When the fuel evaporates in the fuel tank, the vapor passes through vent hoses or tubes to

the canister filled with charcoal and the canister temporarily holds the vapor in the charcoal. If ECM

determines to draw the gathered vapor into the combustion chambers during certain operating

conditions, it will use vacuum in intake manifold to move it.

Removal

- Turn ignition switch OFF and disconnect the negative (-) battery terminal.

- Remove the fuel tank.

(Refer to Engine Control / Fuel System - "Fuel Tank")

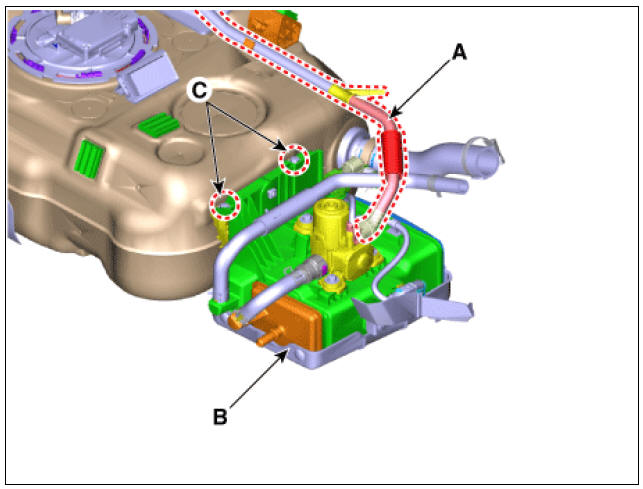

- Disconnect the vapor tube quick-connector (A).

- Remove the canister (B) from the fuel tank after loosening the bolts (C).

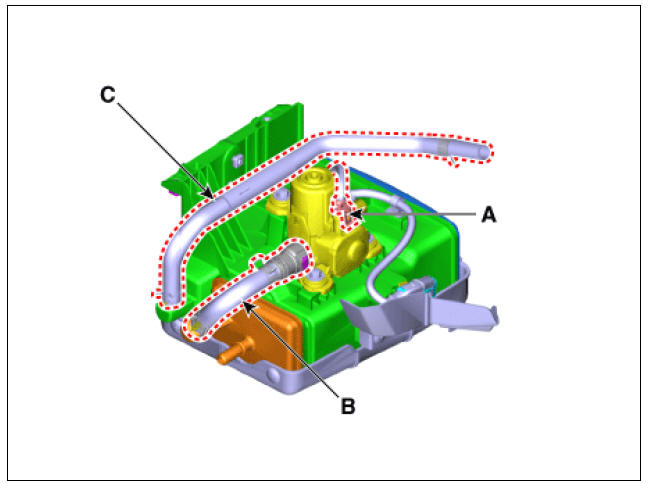

- Disconnect the fuel tank isolation valve (FTIV) connector (A).

- Disconnect the vapor tube quick-connector (B).

- Disconnect the vapor hose (C).

- Remove the fuel tank isolation valve (B) from the canister after loosening the bolts (A).

Inspection

- Check for the following items visually.

- Cracks or leakage of the canister

- Loose connection, distortion, or damage of the vapor hose/tube

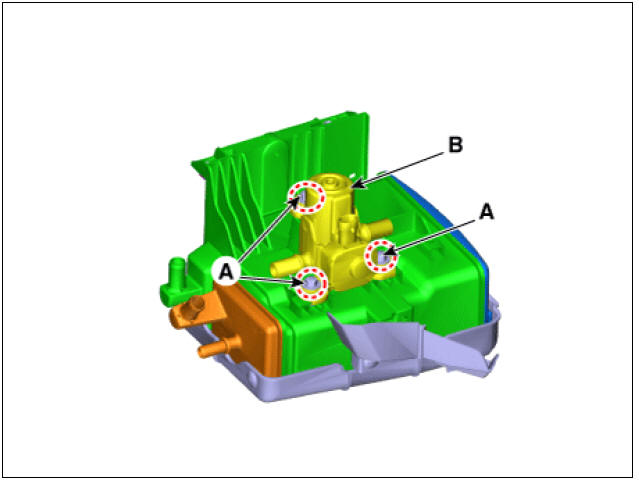

A: Canister → Atmosphere

B: Canister → Intake Manifold

C: Canister → Fuel Tank

Installation

- Install in the reverse order of removal.

READ NEXT:

Fuel Tank Air Filter Repair procedures

Fuel Tank Air Filter Repair procedures

Fuel Filler Cap Description and operation

Description

A ratchet tightening device on the threaded fuel filler cap reduces the

chances of incorrect installation, which seals the fuel

filler. After the gasket on the fuel filler cap and the filler

Exhaust Emission Control System

Exhaust Emission Control System

Description

Exhaust emissions (CO, HC, NOx) are controlled by a combination of engine

modifications and the

addition of special control components.

Modifications to the combustion chamber, intake manifold, camshaft and ignition

system form t

SEE MORE:

Mode Control Actuator Repair procedures

Mode Control Actuator Repair procedures

Mode Control Actuator Components and components location

Mode control actuator (LH)

Mode control actuator (RH)

Description

Located in the heater unit, the mode control actuator adjusts the position of

the mode door by

operating the m

Rear Oil Seal Repair procedures

Rear Oil Seal Repair procedures

Replacement

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any

work related with the high voltage system. Failure to follow the safety

instructions may result in

serious electrical injuries

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us