KIA Niro: Measuring insulation resistance using an insulation tester

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to read and follow the "High Voltage Shut-off Procedures" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Shut off the high voltage circuit.

(Refer to Hybrid Control System - "High Voltage Shut-off Procedures")

- Remove the rear seat cushion.

(Refer to Body - "Rear Seat Assembly")

- Remove the rear door scuff trim.

(Refer to Body - "Door Scuff Trim")

- Remove the inlet cooling duct..

(Refer to High Voltage Battery Cooling System - "Cooling Duct")

- Open the high voltage battery cushion (A) in the direction of an arrow.

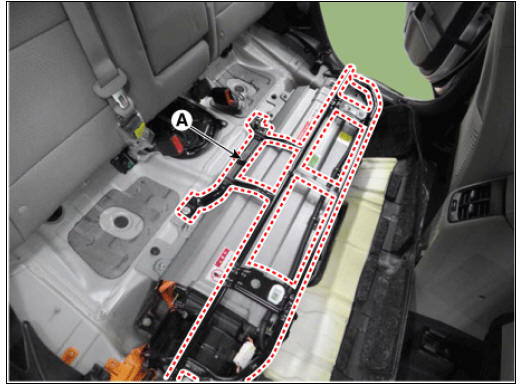

- Remove the upper frame (A) after loosening the mounting bolts and nuts.

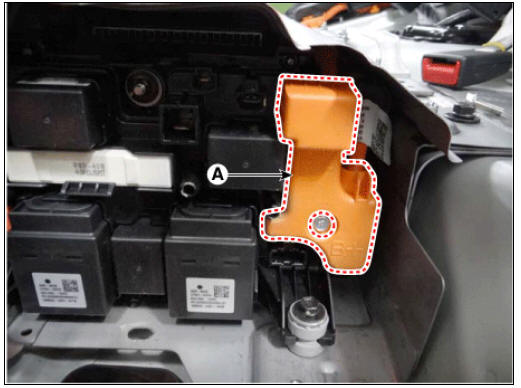

- Remove the high voltage cable cover (A) after loosening the mounting bolt.

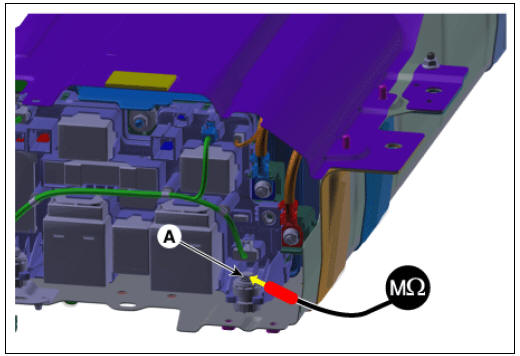

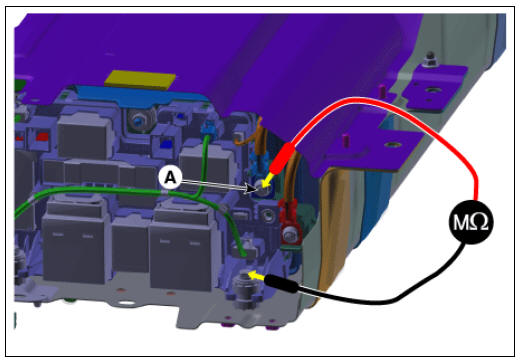

- Connect the insulation tester (-) terminal (A) to the battery system case (or ground).

- Connect the insulation tester (+) terminal to the high voltage battery (+) and (-). Measure the resistance.

Measure the isolation resistance on the power relay assembly high voltage power terminal (+))

(1) Connect the insulation tester (+) terminal to the (+) PRA high voltage power terminal (A).

(2) Supply 500V through the insulation tester and wait one minute to measure the stable resistance.

(3) Check the isolation resistance.

Normal insulation resistance range : Above 1.0 MΩ (20ºC (68ºF))

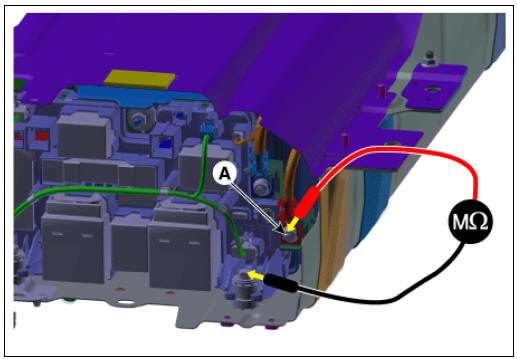

Measure the isolation resistance on the power relay assembly high voltage power terminal (-)

- Connect the insulation tester (+) terminal to the (-) PRA high voltage power terminal (B).

- Supply 500V through the insulation tester and wait one minute to measure the stable resistance.

- Check the isolation resistance.

Normal insulation resistance range : Above 1.0 MΩ (20ºC (68ºF))

Measure the isolation resistance on the power relay assembly inverter power terminal (+)

Warning

When measuring the insulated resistance on each PRA inverter, use a

contact pin to prevent damage on the connector

and for more accurate measurement.

- Connect the insulation tester (+) terminal to the (+) PRA inverter power terminal (A).

- Supply 500V through the insulation tester and wait one minute to measure the stable resistance.

- Check the isolation resistance.

Normal insulation resistance range : Above 1.0 MΩ (20ºC (68ºF))

Measure the isolation resistance on the power relay assembly inverter power terminal (-)

Warning

When measuring the insulated resistance on each PRA inverter, use a

contact pin to prevent damage on the connector

and for more accurate measurement.

- Connect the insulation tester (+) terminal to the (-) PRA inverter power terminal (B).

- Supply 500V through the insulation tester and wait one minute to measure the stable resistance.

- Check the isolation resistance.

Normal insulation resistance range : Above 1.0 MΩ (20ºC (68ºF))

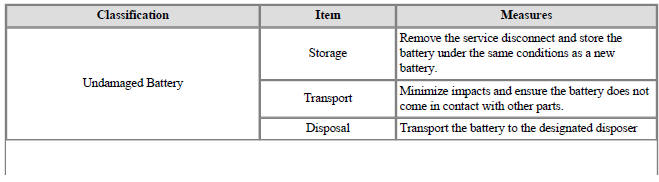

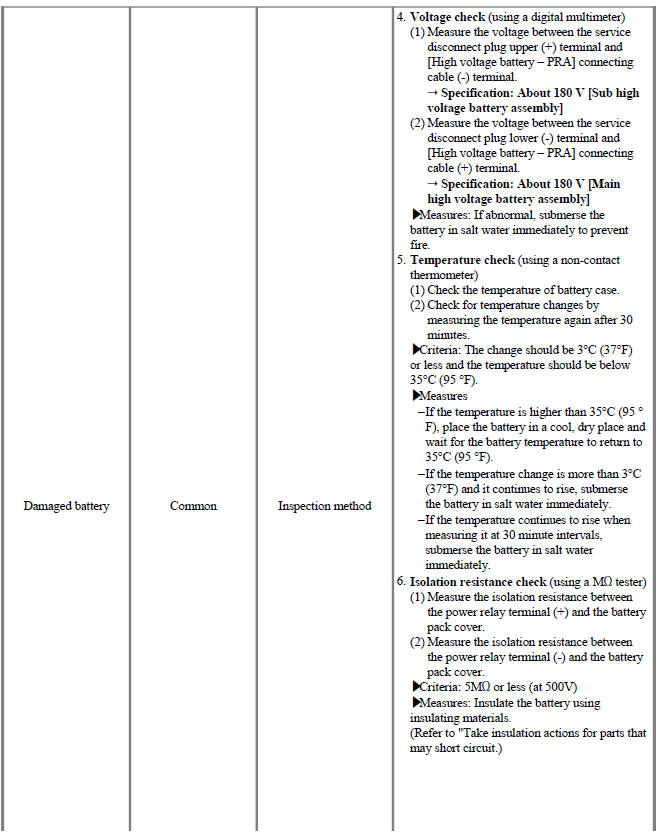

Handling Guide for Storing, Transporting, and Disposing of High Voltage Battery Systems

- High voltage battery system handling process

- Defective high voltage battery system handling / Inspection

READ NEXT:

Voltage Check

Voltage Check

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any work related with the high

voltage system. Failure to follow the safety instructions may result in serious

electrical injuries.

Measu

Service Highlight / Inspection Mode Procedures

Service Highlight / Inspection Mode Procedures

Procedure for entering engine forced activation mode

If the engine needs to be running constantly while the vehicle is stopped to

inspect emission gas or

perform maintenance on the vehicle, follow below procedure to enter engine

forced activati

SEE MORE:

Oil Level Check

Oil Level Check

Remove the under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

Remove the oil filler plug (A or B).

Check the condition of the oil and make sure that it is at the proper

level (A).

Inst

Front Disc Brake

Front Disc Brake

Front Disc Brake Components and components location

Bleed screw

Caliper body

Pad inner shim

Brake pad

Pad return spring

Caliper carrier

Pad retainer

Removal

Remove the wheel & tire.

Remove the caliper hose bracket bol

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us