KIA Niro: Heater Pipe | Active Air Flap (AAF) Repair procedure

- Disconnect the battery negative terminal.

- Loosen the drain plug, and drain the engine coolant. Remove the reservoir cap to help drain the coolant faster.

(Refer to Cooling System - "Coolant")

- Remove the air cleaner assembly.

(Refer to Intake and Exhaust System - "Air Cleaner")

- Remove the water temperature control assembly.

(Refer to Cooling System - "Water Temperature Control Assembly")

- Remove the intake manifold.

(Refer to Intake and Exhaust System - "Intake Manifold")

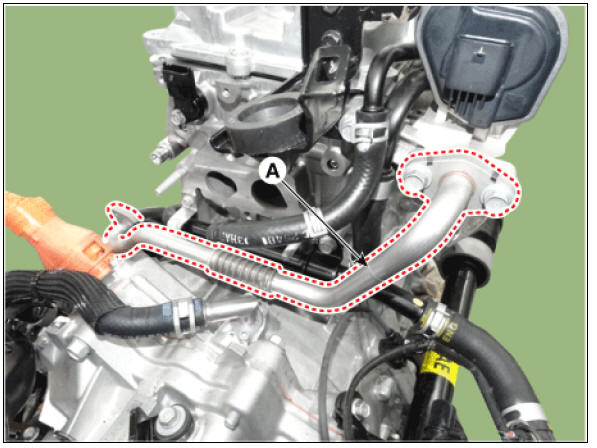

- Remove the electric EGR control valve cooler pipe (A).

Tightening torque : 18.6 - 23.5 N.m (1.9 - 2.4 kgf.m, 13.7 - 17.4 lb-ft)

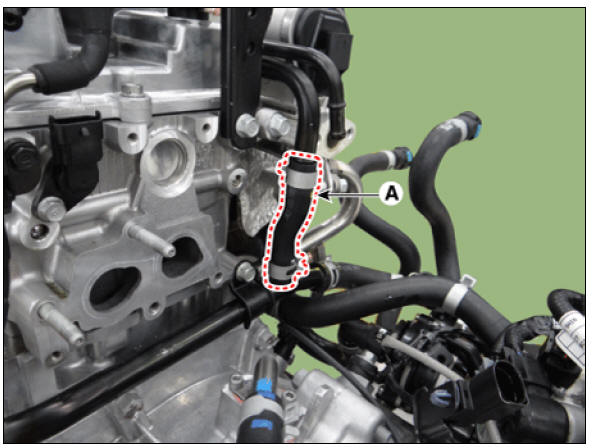

- Disconnect the coolant hose (A).

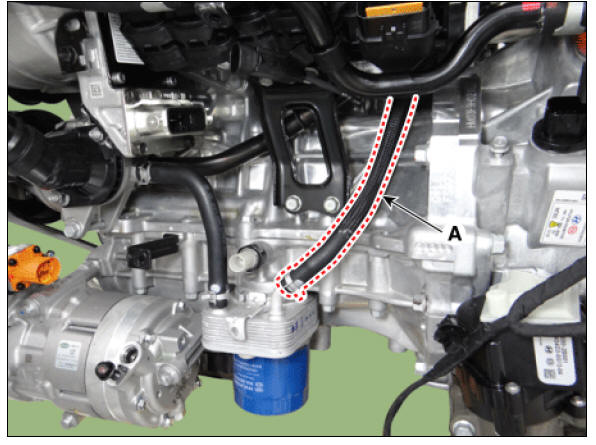

- Disconnect the oil cooler hose (A).

- Remove the heater pipe (A).

Tightening torque : 18.6 - 23.5 N.m (1.9 - 2.4 kgf.m, 13.7 - 17.4 lb-ft)

Warning

- When assembling the heater pipe, make sure that there is no foreign substance in the O-ring gasket.

- Be sure to apply antifreeze on the O-ring gasket before inserting the heater pipe to the water pump housing.

- Install in the reverse order of removal.

- Fill the radiator with coolant and check for leaks.

(Refer to Cooling System - "Coolant")

- Start engine and check for leaks.

- Recheck the coolant level.

Active Air Flap (AAF) Repair procedures

Active Air Flap (AAF) Description and operation

Description

The system receives information from ECU, FATC, TCU, MCU and LDC via CAN communication .

With this information, the active air flap (AAF) controls the motor properly then the air flaps adjust air flow from radiator grille.

During high speed driving, it will reduce the air resistance by closing the air flaps. This improves the fuel efficiency and enhance the driving stability. If overheat occurs, the system will open the air flaps to drop the temperature.

During the A/C operation, the system will open the air flaps to maintain the refrigerant pressure. The system will close the air flaps to warm up the engine rapidly during cold start.

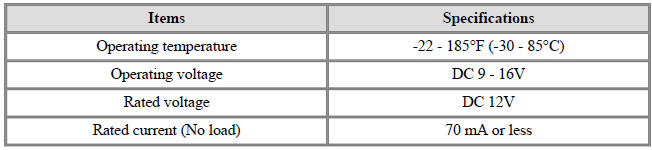

Specifications

Schematic Diagram

Active Air Flap (AAF) Repair procedures

Removal and Installation

- Remove the air duct.

(Refer to Intake and Exhaust System - "Air Cleaner")

- Remove the front bumper cover.

(Refer to Body (Interior and Exterior) - "Front Bumper Cover")

- Disconnect the high pitch horn connector (A).

- Disconnect the low pitch horn connector (A).

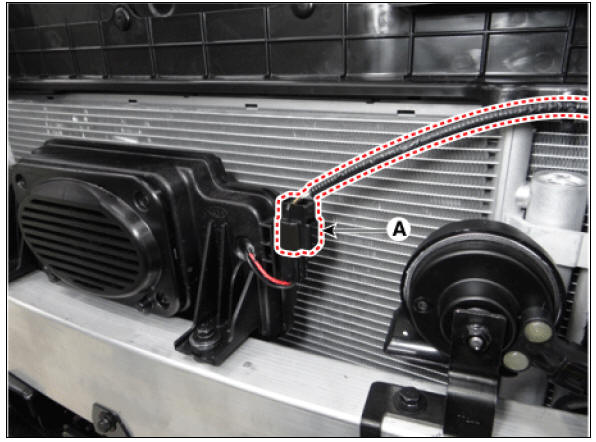

- Disconnect the virtual engine sound speaker (VESS) speaker connector (A).

- Disconnect the advents smart cruise control (ASCC) connector (A)

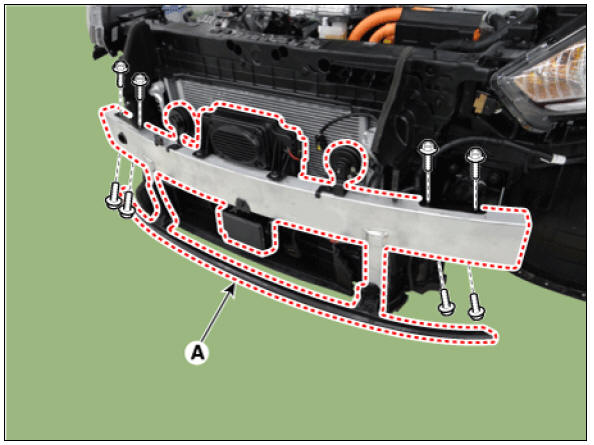

- Remove the front bumper beam (A).

Tightening torque : 7.8 - 9.8 N*m (0.8 - 1.0 kgf*m, 5.8 - 7.2 lb*ft)

- Remove the ambient temperature sensor (A)

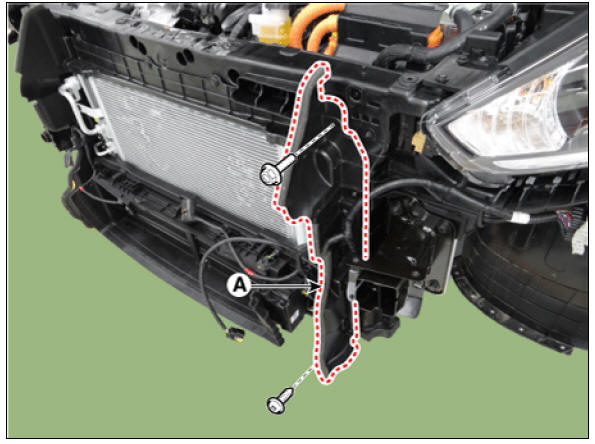

- Remove the air guard (A).

Tightening torque : 3.9 - 5.9 N*m (0.4 - 0.6 kgf*m, 2.9 - 4.3 lb*ft)

RH

LH

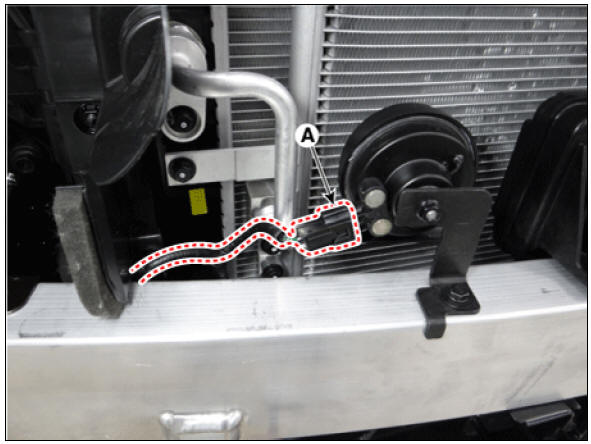

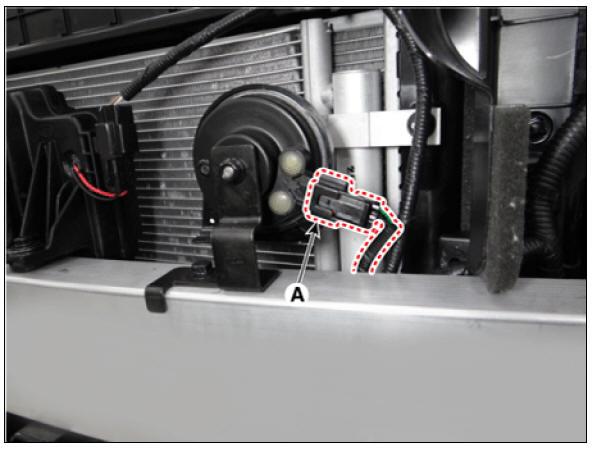

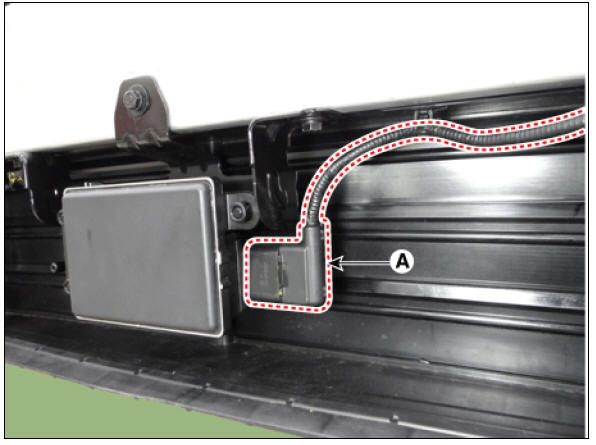

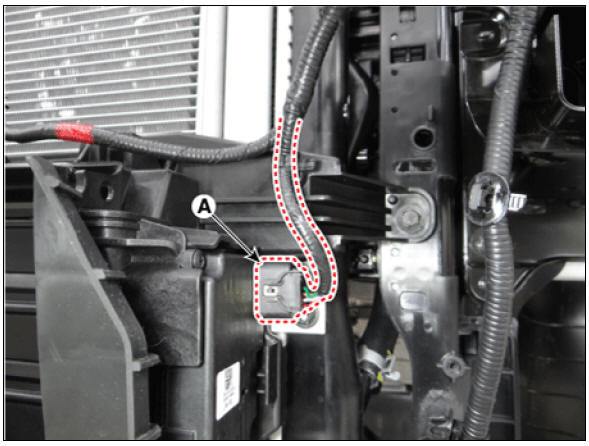

- Disconnect the active air flap (AAF) connector (A).

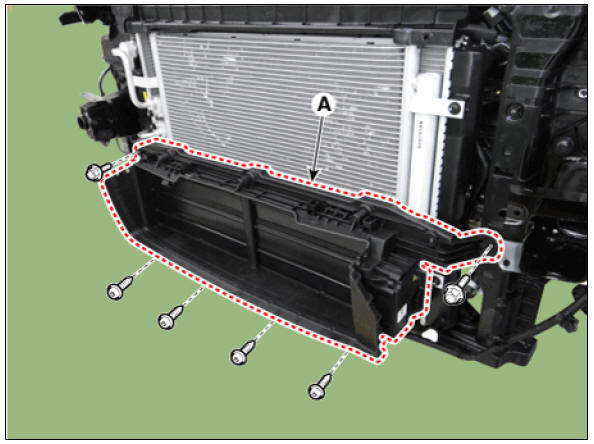

- Remove the active air flap (AAF) (A).

Tightening torque : 7.8 - 9.8 N*m (0.8 - 1.0 kgf*m, 5.8 - 7.2 lb*ft)

- Install in the reverse order of removal.

Disassembly

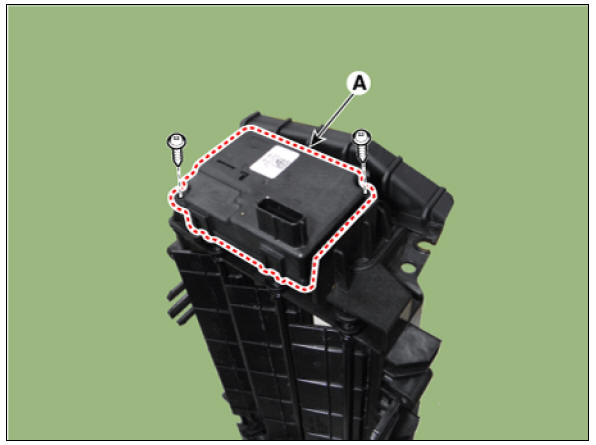

- Remove the active air flap (AAF) actuator (A).

Tightening torque : 1.5 - 2.5 N*m (0.15 - 0.25 kgf*m, 1.1 - 1.8 lb*ft)

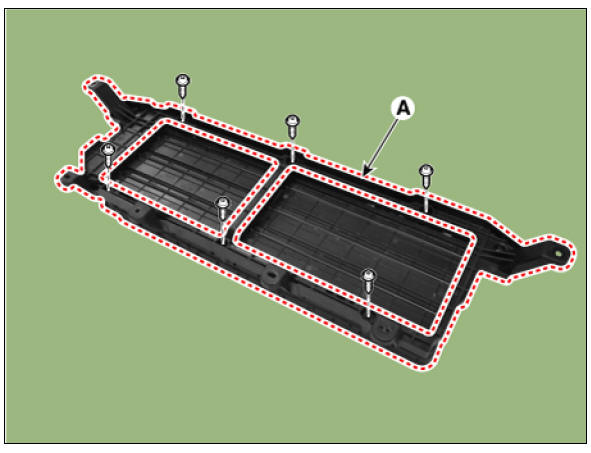

- Remove the active air flap (AAF) duct (A).

Tightening torque : 2.0 - 3.9 N*m (0.2 - 0.4 kgf*m, 1.4 - 2.9 lb*ft)

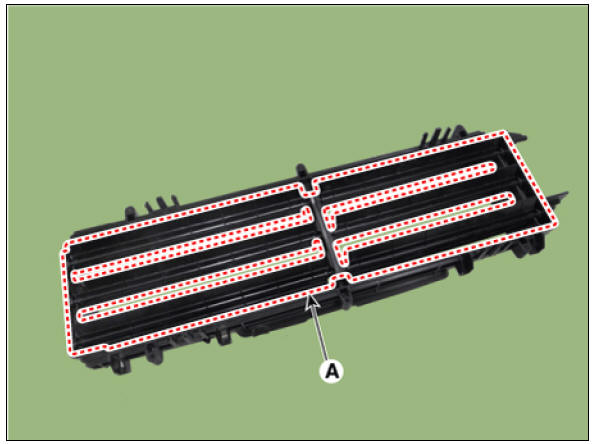

- Remove the air flap (A).

- Assemble in the reverse order of disassembly.

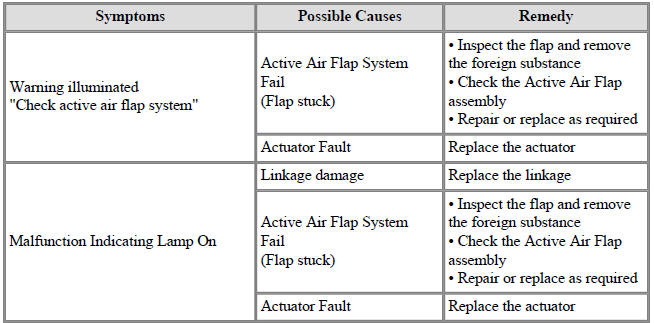

Active Air Flap (AAF) - Troubleshooting

Symptoms:

Warning illuminated "Check active air flap system"

Possible Causes :

Active Air Flap System Fail (Flap stuck)

Remedy :

-

Inspect the flap and remove the foreign substance

-

Check the Active Air Flap assembly

-

Repair or replace as required

Possible Causes :

Actuator Fault

Remedy :

Replace the actuator

Symptoms:

Malfunction Indicating Lamp On

Possible Causes :

Linkage damage

Remedy :

Replace the linkage

Possible Causes :

Active Air Flap System Fail (Flap stuck)

Remedy :

-

Inspect the flap and remove the foreign substance

-

Check the Active Air Flap assembly

-

Repair or replace as required

Possible Causes :

Actuator Fault

Remedy :

Replace the actuator

After performing repairs, clear Diagnostic Trouble Codes (DTC) and check the warning and

Malfunction Indicating Lamp.

READ NEXT:

Fly Wheel Repair procedures

Fly Wheel Repair procedures

Components

Water jacket insert

Cylinder block

Oil ring

Rear oil seal

Crankshaft upper bearing

Thrust bearing

Crankshaft

Pilot bearing

Crankshaft lower bearing

Crankshaft lower bearing cap

Ladder frame

Piston ring

Pisto

SEE MORE:

Vehicle safety system

Vehicle safety system

Anti-lock Brake System (ABS)

The Anti-lock Brake System (ABS) prevents

the wheels from locking to steer

and stabilize the vehicle.

If the ABS warning light ( ) stays

on,

contact a professional workshop as soon

as possible. Kia recommends to

Smart Cruise Control malfunction

Smart Cruise Control malfunction

A: Check Smart Cruise Control System

When Smart Cruise Control is not working

properly, the warning message will

appear, and the ( ) warning light

will

appear on the cluster. Have Smart

Cruise Control be inspected by a professional

worksh

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us