KIA Niro: Cooling Fan Repair procedures | Cooling Fan Assembly

Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual / Engine Mechanical System / Cooling System / Cooling Fan Repair procedures | Cooling Fan Assembly

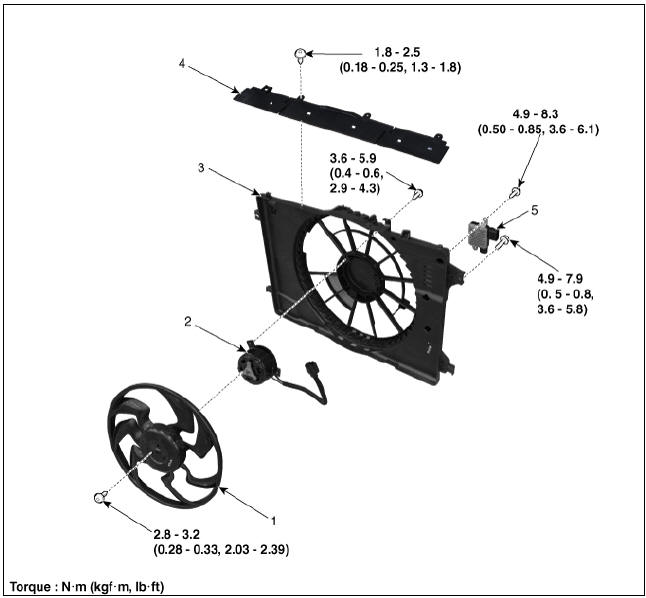

Cooling Fan Components and components location

Components

- Cooling fan

- Cooling fan motor

- Cooling fan shroud

- Air dam

- Cooling fan controller (PWM)

Description

Controls the cooling fan motor voltage depending on the duty output from the ECU (Freq.: 300Hz).

Signal from the ECU to the PWM (SI: 300Hz)

Specifications

Circuit Diagram

PWM Circuit Diagram

Cooling Fan Assembly

Removal and

Installation

- Disconnect the negative battery terminal.

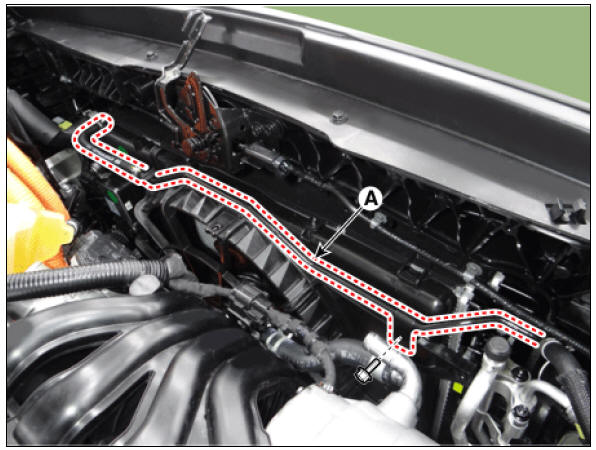

- Remove the air cleaner and air duct A.

(Refer to Intake and Exhaust System - "Air Cleaner")

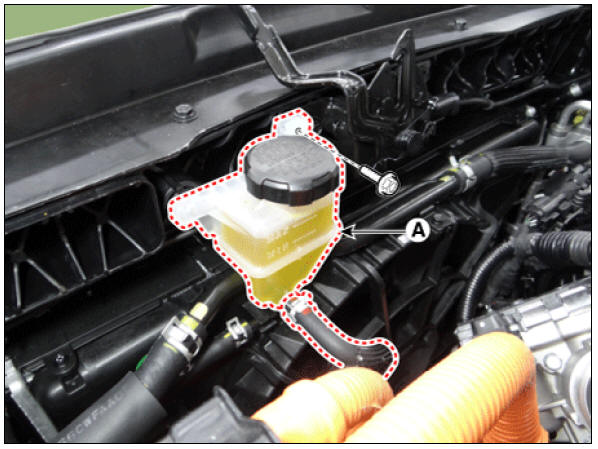

- Separate the engine clutch reservoir tank (A).

Tightening torque : 3.9 - 5.9 N*m (0.4 - 0.6 kgf*m, 2.9 - 4.3 lb*ft)

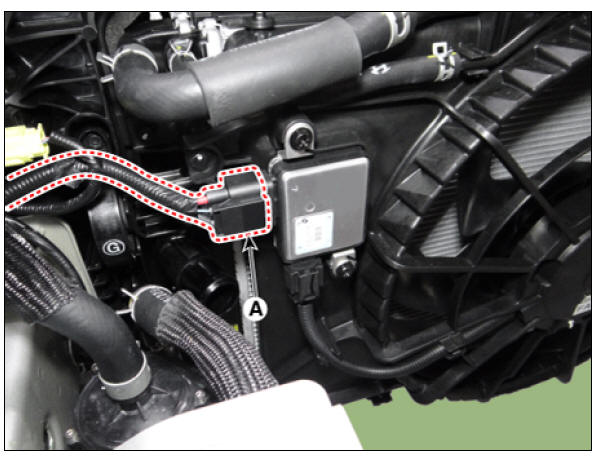

- Disconnect the cooling fan control module (PWM) connector (A).

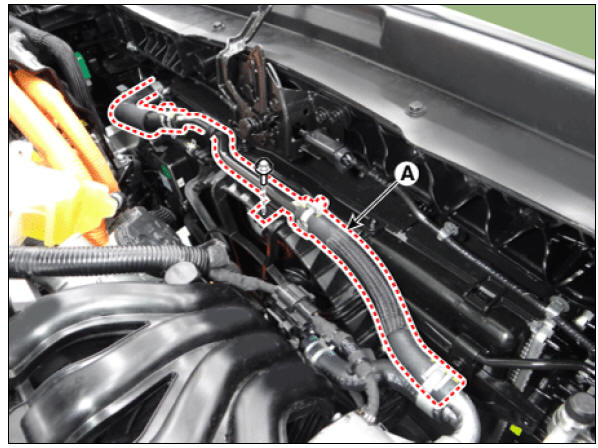

- Remove the hybrid starter generator coolant hose & pipe (A) from the cooling fan shroud.

Tightening torque : 7.8 - 11.8 N*m (0.8 - 1.2 kgf*m, 5.8 - 8.7 lb*ft)

- Separate the radiator coolant pipe (A) from the cooling fan shroud.

Tightening torque : 7.8 - 11.8 N*m (0.8 - 1.2 kgf*m, 5.8 - 8.7 lb*ft)

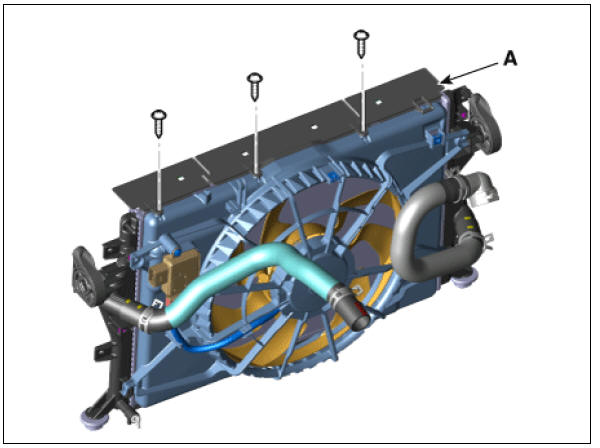

- Remove the air dam (A).

Tightening torque : 1.8 - 2.5 N*m (0.18 - 0.25 kgf*m, 1.3 - 1.8 lb*ft)

- Remove the cooling fan assembly (A).

Tightening torque : 4.9 - 8.3 N*m (0.5 - 0.8 kgf*m, 3.6 - 6.1 lb*ft)

- Install in the reverse order of removal.

READ NEXT:

Cooling Fan Control Module (PWM) | Radiator

Cooling Fan Control Module (PWM) | Radiator

Disconnect the battery negative terminal.

Remove the air duct.

(Refer to Intake and Exhaust System - "Air Cleaner")

Disconnect the cooling fan control module (PWM) connector (A) and cooling fan motor

SEE MORE:

How to connect

How to connect

Outdoor (if equipped)

Open the cover of the V2L connector.

Close the cover after connecting

home appliances and electronic products

to the power outlet.

Connect the V2L connector to the

charging hole on the vehicle.

Pr

Engine Mechanical System / Troubleshooting

Engine Mechanical System / Troubleshooting

Symptoms :

Engine misfire with abnormal internal lower engine noises

Suspected area → Remedy

Worn crankshaft bearings → Replace the crankshaft and bearings as requ

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us