KIA Niro: Compression Pressure Inspection

Warning

If the there is lack of power, excessive oil consumption or poor fuel economy, measure the compression pressure.

- Warm up and stop the engine.

Allow the engine to warm up to normal operating temperature.

- Remove the air cleaner.

(Refer to Intake and Exhaust System - "Air Cleaner")

- Remove spark plugs.

(Refer to Engine Electrical System - "Spark Plug")

- Check cylinder compression pressure.

(1) Insert a compression gauge into the spark plug hole. If possible, place the gauge where it can be seen from inside the vehicle.

(2) Attach the KDS.

- Connect the cable of KDS to the data link connector.

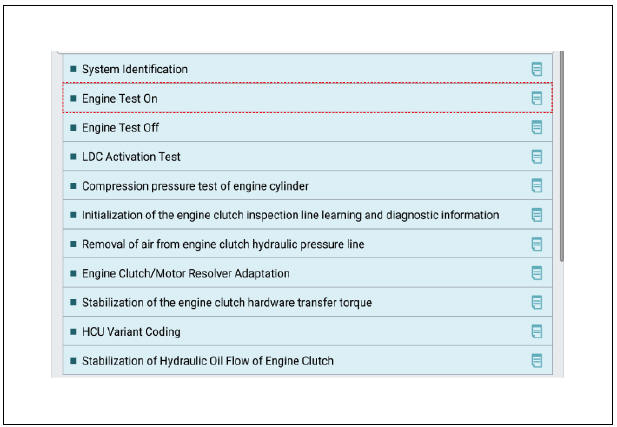

- Select the vehicle model and then the HCU system.

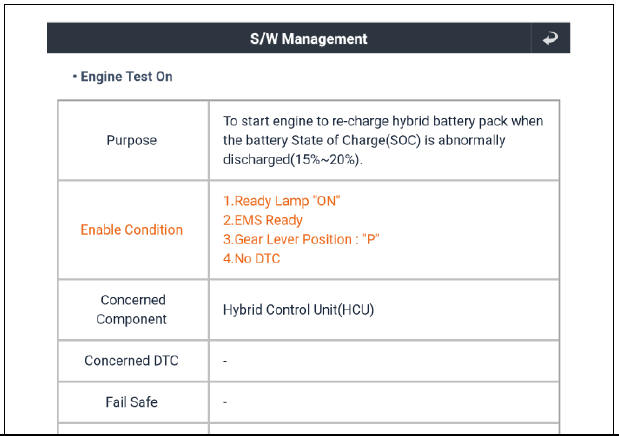

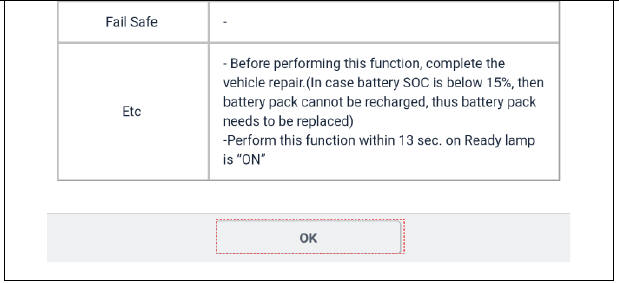

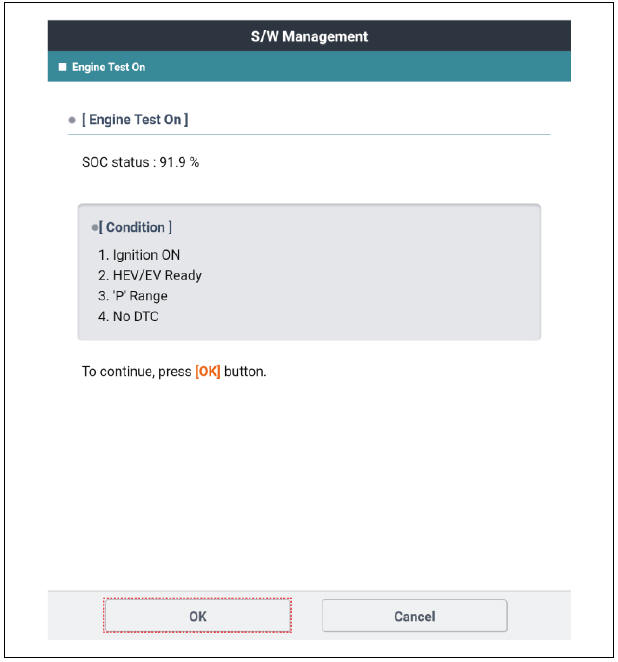

- Select the "Engine Test On". See the screens below.

(3) While cranking the engine, measure the compression pressure.

- With the Brake pedal depressed, press the Start/Stop Button (SSB) one time.

- If the engine cranks, let it crank about 8 to 10 cycles (until the gauge readings stabilizes) then press the SSB one time to stop the engine from cranking.

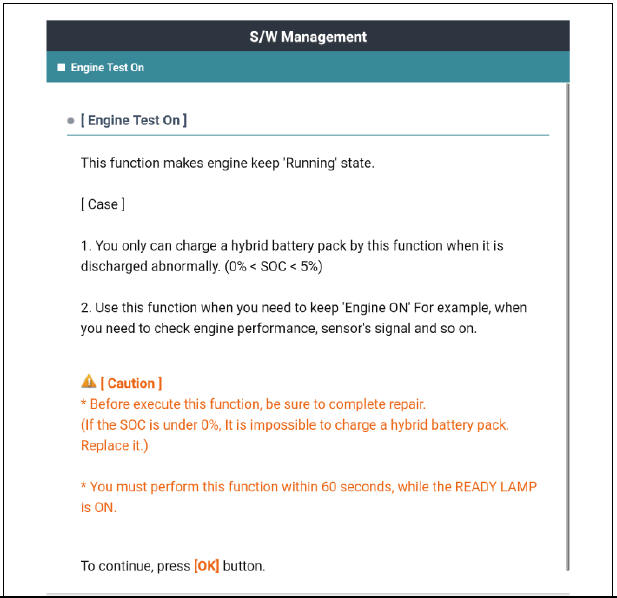

- If the engine does not crank on its own when the SSB is pressed, the KDS should be used to crank the engine. While in the "Engine Test On" follow the instruction on the screen.

- The "Engine Test On" will start the engine cranking. After the compression readings stabilize (8-10 cycles), press the SSB one time to stop the cranking.

(4) Repeat steps (1) through (3) for each cylinder.

Warning

Be sure ignition is in the OFF mode between each cylinder test.

This measurement must be done while the engine is still near operating temperature.

Compression pressure :

981kPa (10.0kgf/cm², 142psi) / 300 - 350rpm

Minimum pressure :

834kPa (8.5kgf/cm², 121psi) / 300 - 350rpm

Difference between each cylinder :

100kPa (1.0kgf/cm², 15psi) or less

(5) If the cylinder compression in 1 or more cylinders is low, pour a small amount of engine oil into the cylinder through the spark plug hole and repeat steps (1) through (3) for cylinders with low compression.

- If adding oil helps the compression, it is likely that the piston rings and/or cylinder bore are worn or damaged.

- If pressure stays low, a valve may be sticking or seating is improper, or there may be leakage past the gasket.

- Reinstall spark plugs.

Tightening torque : 14.7 - 24.5 N*m (1.5 - 2.5 kgf*m, 10.8 - 18.1 lb*ft)

- Install ignition coils.

Tightening torque : 9.8 - 11.8 N*m (1.0 - 1.2 kgf*m, 7.2 - 8.7 lb*ft)

- Connect the injector connectors and ignition coil connectors.

- Some DTC's may exist after the inspection test and may need to be manually cleared with KDS.

READ NEXT:

Engine Mechanical System / Troubleshooting

Engine Mechanical System / Troubleshooting

Symptoms :

Engine misfire with abnormal internal lower engine noises

Suspected area → Remedy

Worn crankshaft bearings → Replace the crankshaft and bearings as requ

Cooling System

Cooling System

Components

Reservoir tank

Reservoir hose & pipe

Radiator

Radiator upper hose

Radiator lower hose

Radiator upper mounting bracket (RH)

Radiator upper mounting bracket (LH)

Radiator lower mounting insulator (RH)

Radiator low

Coolant Repair procedures

Coolant Repair procedures

Warning

Never remove the radiator cap when the engine is hot. Serious

scalding could be caused by hot fluid under

high pressure escaping from the radiator.

Warning

When pouring engine coolant, shut the relay box lid and be careful

not to spil

SEE MORE:

Door locks outside the vehicle

Door locks outside the vehicle

Locking/unlocking with the smart key

Operation

Press the front door handle button

(driver's side).

Hazard warning lights will blink and

the chime will sound.

Locking: Once

Unlocking: Twice

Operating condition(s)

All

Limitations of Rear Cross-Traffic

Collision-Avoidance Assist

Limitations of Rear Cross-Traffic

Collision-Avoidance Assist

Rear Cross-Traffic Collision-Avoidance

Assist may not operate properly, or it

may operate unexpectedly under the

following circumstances:

Departing from where trees or grass

are overgrown

Departing from where roads are wet

Speed of the a

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us