KIA Niro: AHB(Active Hydraulic Boost) System / Description And Operation

Regeneration Brake System

During deceleration or braking of an electric vehicle or HEV, the drive motor acts as an alternator and charges the battery by converting the vehicle's kinetic energy generated during braking into electrical energy. Regenerative braking amount depends on the vehicle speed, battery SOC, etc. Achieves significant improvement in fuel efficiency in city driving with repeated acceleration and deceleration.

Regenerative Braking Cooperation Control (RBC)

The brake force apportion is distributed by controlling hydraulic braking and the total brake force (hydraulic + regenerative brake) output that the driver requires is generated.In the case of regenerative brake failure, the total brake force that the driver requires is supplied by the hydraulic brake system.

The AHB system is composed of the Pressure Source Unit (PSU), the Intergrated Brake Actuation Unit (IBAU). First, the PSU generates the hydraulic pressure required for braking.Similar to the boosting effect when the driver steps on the brake pedal in a system equipped with a vacuum booster, the hydraulic pressure stored in the cylinder is supplied to provide pressure throughout the entire brake line.Second, the IBAU delivers pressure that is generated by the PSU to a caliper on each wheel. It is connected to the brake pedal to detect the brake force that is required by the driver, and to generate a brake feeling.The IBAU carries out the ABS, TCS, and ESC functions as in conventional vehicles.

AHB System Operation Principals

- Initial Status

High pressure (180 bar) between the PSU and the IBAU is generated consistently. Therefore, before removing the PSU or the IBAU, high pressure between them should be reduced for safety by conducting "High pressure release mode" of GDS connected.

- Brake operation

Apply Mode : During normal braking, IN valve becomes ON and opens; then, the high pressure generated by PSU is supplied to a caliper on each wheel by IBAU and the brake operation is engaged.Release Mode : During discharging brake, OUT valve opens and IN valve closes; then, the high pressure of brake oil return back to reservoir. At this time, CUT valve is ON and it prevents back flow of brake oil to master cylinder.

- Brake malfunction

If the PSU or the IBAU is broken, IN valve and OUT valve are closed, and CUT valve is off. Therefore, the brake force is generated by only pressing a brake pedal manually by a driver.

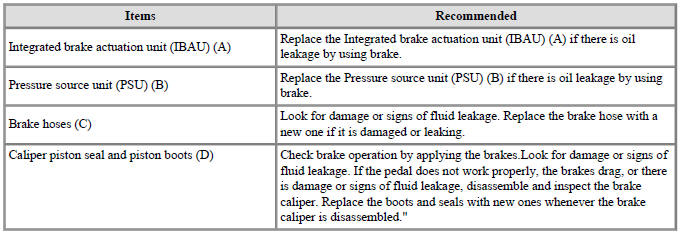

Operation and Leakage Check

Check all of the following items:

READ NEXT:

Brake Actuation Unit Repair procedures

Brake Actuation Unit Repair procedures

Brake Actuation Unit Components and components location

Warning

IBAU(Intergrated Brake Actuation Unit) must not be disassembled.

Integrated Brake Actuation Unit (IBAU) ECU

Reservoir

Pedal Simulator

Integrated Brake Actuation Unit (IBA

Pressure Source Unit Repair procedures

Pressure Source Unit Repair procedures

Pressure Source Unit Components and components location

Warning

PSU (Presser Source Unit) must not be disassembled.

Pressure Source Unit (PSU)

Pressure Source Unit (PSU) connector

Motor

Filler adapter

Bracket

Accumulator

Remova

Brake Line

Brake Line

Brake Line Components and components location

Removal

Disconnect the brake fluid level switch connector, and remove the

reservoir cap.

Remove the brake fluid from the master cylinder reservoir with a

syringe.

Warning

Do not spill

SEE MORE:

Air Conditioning System / Repair Procedures

Air Conditioning System / Repair Procedures

Checking Refrigerant Specifications

Check refrigerant specifications label inside engine room.

Examples

R-134a

R-1234yf

If refrigerant specifications label is not visible, check the

refrigerant service port diameter.

High

pressu

Rear Oil Seal Repair procedures

Rear Oil Seal Repair procedures

Replacement

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any

work related with the high voltage system. Failure to follow the safety

instructions may result in

serious electrical injuries

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us