KIA Niro: Power Cable

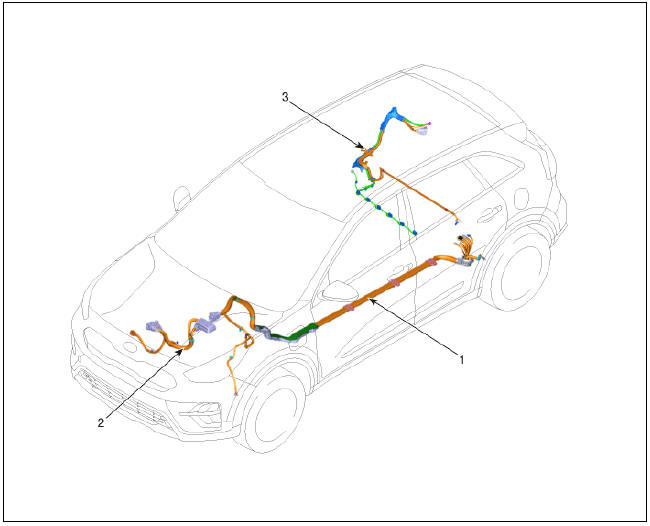

Components

- Power Cable (HPCU↔Main High Voltage Battery System)

- Power Cable (HPCU↔HSG, Electric /C Compressor)

- Power Cable (Main High Voltage Battery System ↔ Sub High Voltage Battery System)

Removal

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to read and follow the "High Voltage Shut-off

Procedures" before doing any work related with the high voltage system.

Failure to follow the safety instructions may result in serious electrical injuries.

Engine Room Fuse & Relay Box, HPCU ↔ Auxiliary 12V Battery & High Voltage Battery System Assembly

- Shut off the high voltage circuit.

(Refer to Hybrid Control System - "High Voltage Shutoff Procedure")

- Remove the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

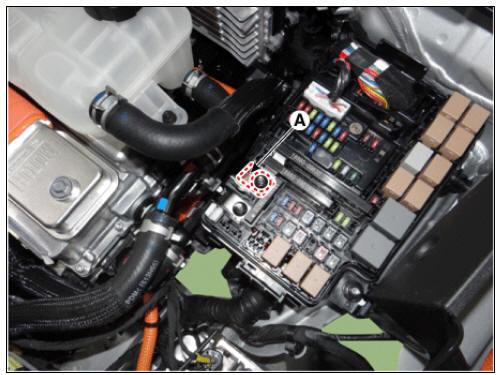

- Disconnect the power cable (A) from the HPCU.

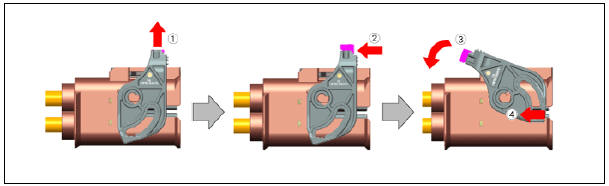

Warning

Remove the inverter power cale in the follwing order.

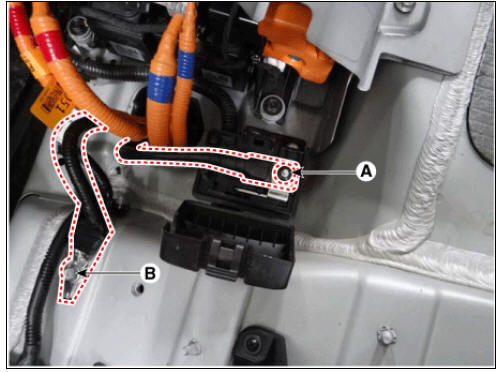

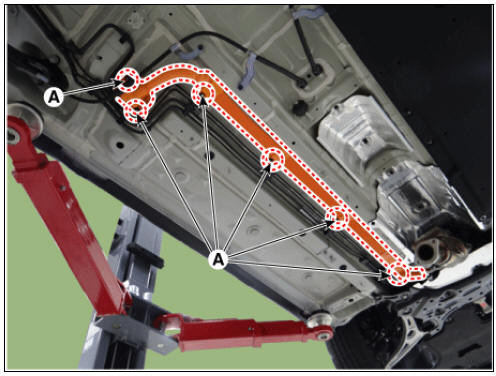

- Disconnect the clamp (A).

Auxiliary 12V battery (+) cable mounting nut (Engine room fuse & relay box)

:

10.8 - 13.7 N*m (1.1 - 1.4 kgf*m, 8.0 - 10.1 lb*ft)

- Remove the high voltage battery rear cover.

(Refer to High Voltage Battery System - "Case")

- Remove the high voltage inlet duct.

(Refer to High Voltage Battery Cooling System - "Cooling Duct")

- Disconnect the inverter power (+) (A) , inverter power (+) (B), OBC power connector (+) (C) and OBC power connector (-) (D)

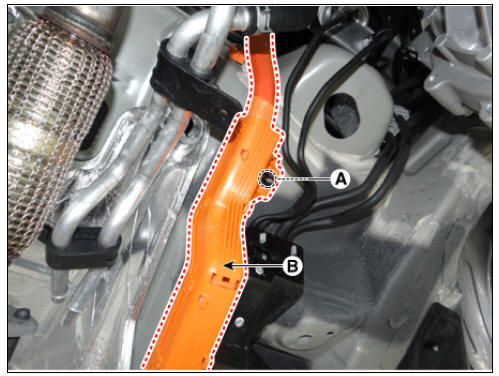

- Disconnect the auxiliary 12V battery positive (+) cable after loosening the mounting nut (A).

- Disconnect the ground cable after loosening the mounting bolt (B).

Ground cable mounting bolt (M6) (Trunk chassis ground) : 10.8 - 13.7 N*m (1.1 - 1.4 kgf*m, 8.0 - 10.1 lb*ft)

- Lift the vehicle.

- Remove the front sub frame.

(Refer to Suspension System - "Sub Frame")

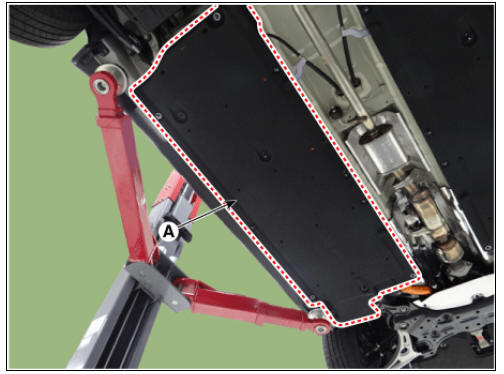

- Remove the side under cover (A) after loosening the mounting bolts and nuts.

- Remove the power cable (B) after loosening the mounting nuts (A).

Power cable mounting nut : 10.8 - 13.7 N*m (1.1 - 1.4 kgf*m, 8.0 - 10.1 lb*ft)

READ NEXT:

Power Cable (HPCU-HSG, Electric /C Compressor). Main High Voltage Battery System, Sub High Voltage Battery System

Power Cable (HPCU-HSG, Electric /C Compressor). Main High Voltage Battery System, Sub High Voltage Battery System

Turn ignition switch OFF and disconnect the negative (-) battery cable.

Shut off the high voltage.

(Refer to "High voltage Shut-off Procedures")

Disconnect the motor power cable connector (A) and HSG p

ON-Board Charger (OBC)

ON-Board Charger (OBC)

HPCU (Hybrid Power Control Unit)

ON-Board Charger (OBC)

Normal Chage Port

Power Cable (HPCU↔HSG, Electric /C Compressor)

Power Cable (HPCU↔Main High Voltage Battery System)

Power Cable

SEE MORE:

Piston, rings

Piston, rings

Clean piston.

(1) Using a gasket scraper, remove the carbon from the piston top.

(2) Using a groove cleaning tool or broken ring, clean the piston ring grooves.

(3) Using solvent and a brush, thoroughly clean the piston.

Warning

Do not

LCD display

messages

LCD display

messages

Ready to drive

A: Ready to start driving

This message is displayed when the

vehicle is ready to be driven.

Check regenerative brakes

A: Check regenerative brakes

This message is displayed when the

brake performance is low or the regene

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us