KIA Niro: Oil Cooler Repair procedures | Oil Pressure Switch Repair procedures

Removal

- Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

- Drain the engine oil and then remove the oil filter.

(Refer to Lubrication System - "Engine Oil")

- Drain the coolant.

(Refer to Cooling System - "Coolant")

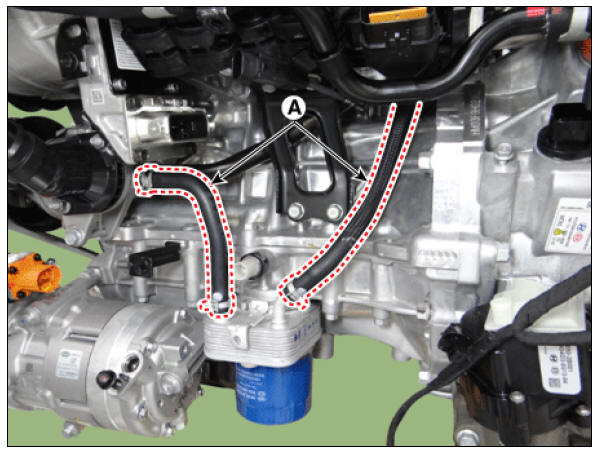

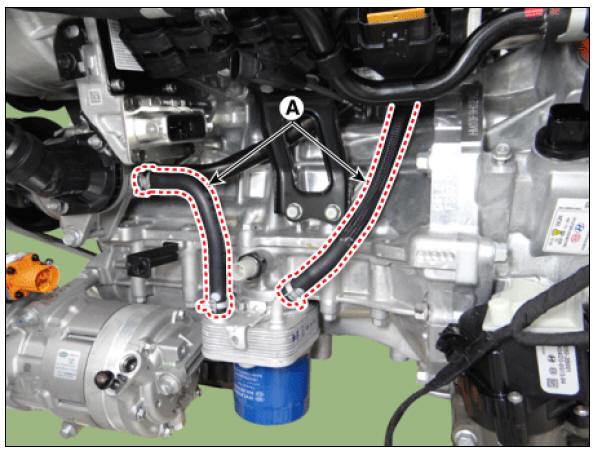

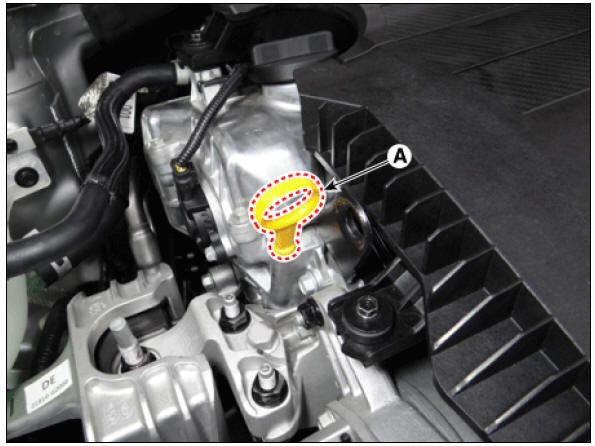

- Disconnect the coolant hose (A).

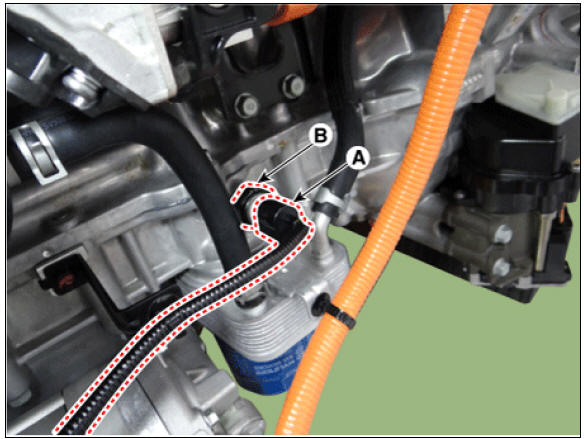

- Unfasten the fixing bolt (A) and then remove the oil cooler assembly (B).

Installation

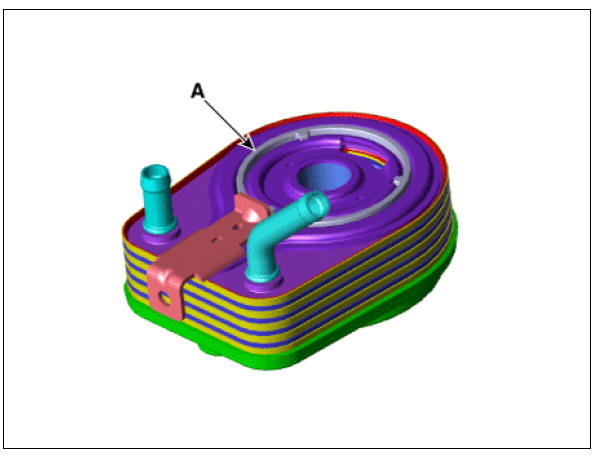

- Apply engine oil to the oil cooler packing surface (A).

- Install the oil cooler (A) with a fixing bolt (B).

Tightening torque : 50.1 - 55.9 N*m (5.1 - 5.7 kgf*m, 36.9 - 41.2 lb*ft)

Warning

Fix position of oil cooler stopper where oil cooler resists on ladder frame stopper.

- Connect the coolant hose (A).

- Fill the coolant.

(Refer to Cooling System - "Coolant")

- Install the oil filter and then fill the engine oil.

(Refer to Lubrication System - "Engine Oil")

- Install the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

Oil Pressure Switch Repair procedures

Removal and

Installation

- Disconnect the battery negative terminal.

- Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

- Disconnect the oil pressure switch connector (A).

- Remove the oil pressure switch (B).

Tightening torque : 9.8 - 11.8 N*m (1.0 - 1.2 kgf*m, 7.2 - 8.7 lb*ft)

- Install in the reverse order of removal.

Warning

When installing the oil pressure switch, apply seal lock to the thread.

Seal lock : THREEBOND 2403

Thickness : 0.2 - 0.4 mm (0.008 - 0.016 in.)

Inspection

- Check the continuity between the terminal and the body with an ohmmeter.

If there is no continuity, replace the oil pressure switch.

- Check the continuity between the terminal and the body when the fine wire is pushed. If there is continuity even when the fine wire is pushed, replace the switch.

- If there is no continuity when a pressure of 50 kPa (0.50 kgf/cm², 7.25 psi) is applied through the oil hole, the switch is operating properly.

Check for air leakage. If air leaks, the diaphragm is broken. Replace it.

Oil Level Gauge & Pipe Repair procedures

Removal and

Installation

- Remove the oil level gauge (A).

- Remove the timing chain cover.

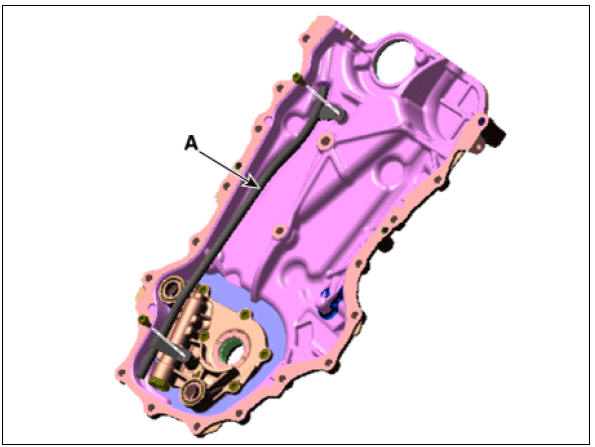

(Refer to Timing System - "Timing Chain Cover") 3. Remove the Oil level gauge pipe (A).

Tightening torque : 8.8 - 13.7 N*m (0.9 - 1.4 kgf*m, 6.5 - 10.1 lb*ft)

- Install in the reverse order of removal.

Removal and

Installation

Warning

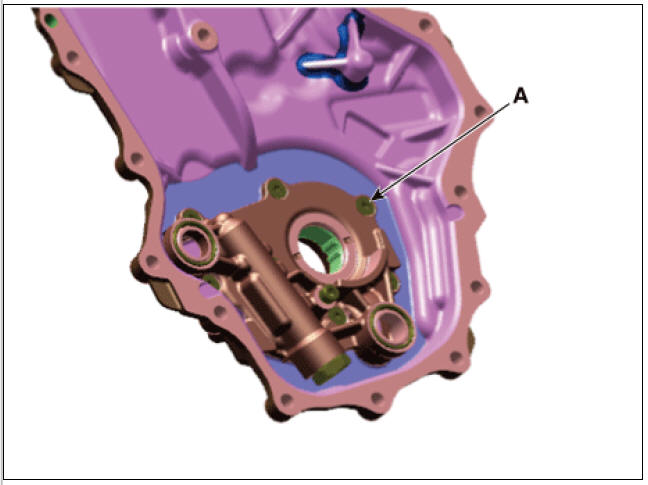

Do not disassemble the oil pump (A) from timing chain cover because it is supplied as timing chain cover & oil pump assembly.

READ NEXT:

Front Oil Seal Repair procedures | Timing Chain Cover Repair procedures

Front Oil Seal Repair procedures | Timing Chain Cover Repair procedures

Components

Front oil seal

Timing chain cover

Variable force solenoid (VFS) valve

O-ring

Timing chain tensioner

Timing chain tensioner arm

Timing chain guide

Timing chain

Timing chain cam guide

Front

SEE MORE:

Highway Lane Change Assist operating- (Kia Niro EV only)

Highway Lane Change Assist operating- (Kia Niro EV only)

Highway Lane Change Assist function

will operate, when you push the turn signal

lever to A or B position while the

function is in the ready state ( )

indicator

is green), and all of the following

conditions are satisfied:

The driver ha

DCT Control Module (TCM), Repair procedures

DCT Control Module (TCM), Repair procedures

Conponent Location

DCT Control Module (TCM)

TCM Connector

TCM Terminal Function

Connector (A)

Connector (B)

Circuit Diagram

Inspection

TCM ground circuit test : Measure the resistance between TCM and chassis grou

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us